Hi All

I know that some of us are having issues with this printer, however if you do manage to get it to work here are some tips.

Firstly forget the slicing system in the printers software just use it as a way to connect to your printer, send the g_codes.

download

Meshmixer at www.meshmixer.com

Slic3r at http://slic3r.org

Meshlab at http://meshlab.sourceforge.net

Now I use Meshmixer to add the support structure to the Model, Slic3r to generate the g_code then upload with 3d create and print.

now Meshlab I use to convert the sketchup file to stl as sometimes the sketchup plugin fails.

Here are the settings for PLA in Slic3r I use which seem to work.

In Print Settings

Layers & Perimeters

Layer Height 0.2

First layer Height 0.2

Perimeter 3

Solid layers top and bottom 3

Seam position random

Infill

Fill density between 25% and 80% depending how strong you want the Model

Fill Pattern Honeycomb

Top & Bottom Fill pattern Rectilinear

Combine every fill layer 1

Only when needed tick

Solid infill layer 3

Fill angle 45 degrees

Solid infill threshold 70 mm2

Infill before perimeter tick

Skirt And Brim

Loops 4

Distance from object 4

Skirt height 1

Minimum Extrusion length 0

Brim width 0

Support Material

Make sure it is not ticked as you will get better results from Meshmix do look on youtube for tutorials.

Speed

Perimeters 30

Small Perimeters 20

External Perimeters 15

Infill 50

Solid Infill 50

Top Solid Infill 50

Support Material 50

Support Material Interface 60

Bridges 60

Gap Fill 20

Travel 80

First Layer Speed 30

The rest of the settings make sure they are set to 0 except Max Print Speed set to 80

Multiple Extruders

Make sure the settings are set to 1 and the tick boxes are empty

Advanced

Make sure all settings are set to 0 except these settings

First Layer 200%

Infill Perimeter Overlap 20%

Bridge Flow Ratio 1

Threads 2

That’s all the setting for this section

Filament Settings

You need to set that according to the material you are using and the recommended settings**.**

Printer Settings

General

Bed Shape Rectangular

Size 140 X 140

Origin 0 0

Extruders 1

G-Code Flavor RepRap

Pressure Advance 0

Vibration Limit 0

Custom G Codes leave alone

Extruder 1

Nozzel Diameter 0.4

Extruder Offset 0 & 0

Length 1.5

Lift Z 0.5

Speed 20

Extra Length On Restart 0

Minimum travel after retraction 1.5

The two boxes not ticked

Length 10

Extra length on restart 0

This should set you up for printing

When you do load the G-code the printer will tell you the bed is heating , But it will not mention the print head. Just let it run.

Now as for the Printer

That square PCB build plate get shot of it as it is useless.

Get hold of some sheet Aluminum the same size as the PCB. Rough the surface with some 80 grit emery paper.

When you get ready to to print spray the Aluminum with cheap Hair Spray, this will help combat warping.

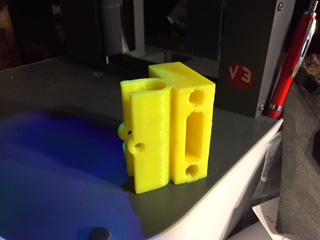

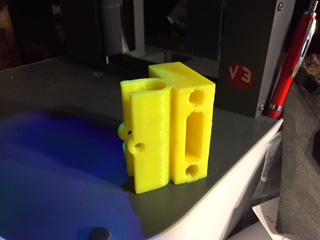

I have added a Photo of the results.

Do search for tutorials on the software packages I have mentioned, but ultimately get a better printer for half the price we had to pay for this thing.