Yeah. I don’t think I have the budget. I’ll just get mine up.and running with new extruders and a board. Then work up from there.

I think you misunderstand how crap he3d products are…sure a tightened frame may help, but if your going to rebuild a printer then do it right and do it once… sticking with a poor frame that needs retightening and resquaring once a week isnt really worth the time…as for sales…meh, i just reccomend parts that i have personally used and know do a great job, i dont make a cent from reccomending anything and Im sure there are others that can do the job, but im not in a place to reccomend them.

There are a few other great printable upgrades like wobble isolators bearing holders for the bottom of z rods one piece motor mount and top frame parts I will this evening compile a list of thingiverse links for you that I would recommend

Ok fair enough all prusa printers suffer from loosening up that’s were a little penetrating thread locker and a few extra nuts are for I am sure that any prusa I1/I2 style would be crap to you it is a 6 year old design how ever your printer the i3 was the evolution of this design and has a few flaws too I am sure as most machines do Glad you enjoy it

That would be great. Thanks!

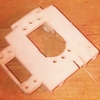

I have a prusa I2. I just installed the e3d titan and e3d hotend. It was a trick to get it on those horizontal parallel rods. Look.

upgrades I would do

x carriage

frame braces

extruder with a mk7 gear

Direct drive 1.75mm filament extruder which work fine for prusa.

It use the standard 50mm M4 holes, and Jhead adaptation.

And is specially designed for 1.75 jhead Nozzles.

[NOTE] V0.6 is the last version

Caution! This is a prototype, it's not sure it...

z rod clamp

z motor mounts

z screw isolator

or

and then find a fan mount kinda like this

these should all be pretty inexpensive and were most of what I did to my machine it made a big difference

with a e3d hotend you should be good to go for quite a while I would just get a heater pcb and

I’ve had good luck with a MKS 1.4 board and and E3D clone hotend on my all metal HE3D Delta 600. The only drawback to the clone hotend is you need to drill and chamfer the push connect fittings.

1 Like

Hobby shops or digikey.com Maybe if you have a radio shack like shop Amazon probably as well

Hmm. Could your motors handle the extra wieght of the Titan extruder? I’m not sure mine could.

Cool. Do you think my x motor can handle the extra weight of a direct drive, or should I keep it a bowden?

I am sure it will be fine

With a good controller they will be fine But if you want to be sure post a pic of the label on the motor if there is one But they look bigger than the motors on my prusa really its not much more load as it’s a pretty low friction setup you might have to adjust your x jerk setting but I can help with that

Interesting. Thanks. I am currently out of town for the holidays. Is there anything specific I should look for on the motor? Also, is there a need for that heat bed electricity rerouter if I go with the board that was suggested below? Is there a specific heated bed that I should invest in?

do you find the solution in this website 3dprintmanual.com

Hey Broncosis. Thanks for the files. I have a question about the x carriage. How would I make it a bowden e3d v6? Would that be possible, and if not do you know of any carriage designs for that specifically? I want it to be bowden, because the direct drive will limit my 3d printing space dramatically. At worst, I would just use the direct drive but I still need it for an e3d (how would I do that?). Thanks again for all your help.

I am sures there is a prusa mount out there on one of the sites I will find it for you in a bit when I get to my computer

That would be great! I’ve been looking as well, but lots of them have the belt tensioner in the middle. Mine would have to be on the back of the carriage.

The adapter works perfectly with E3D type etruder, but it works as well for j-head type.

This design consist in two main parts, the body fits in the printer carriage and the clamp fit the extruder in position with two M3 screw.The bowden tube can...

this would be my first choice

it looks nice a simple and would work with a e3d or any of the knock off’s

but if that fails

This kit aims to convert a "standard" prusa to a bowden set with minimal changes.

You need a standard 50mm extruder mount, and for instance a JHead hot-end, I will made more adapters on demand and with specs ;)

with out the fittings just run the tubing straight into the e3d

should work I know it prints I used it to attempt a 3mm bowden setup long ago