This series will explore the potential of recycling household plastic waste into homemade 3D printing filament. I will look specifically into the potential for cost savings and waste reduction.

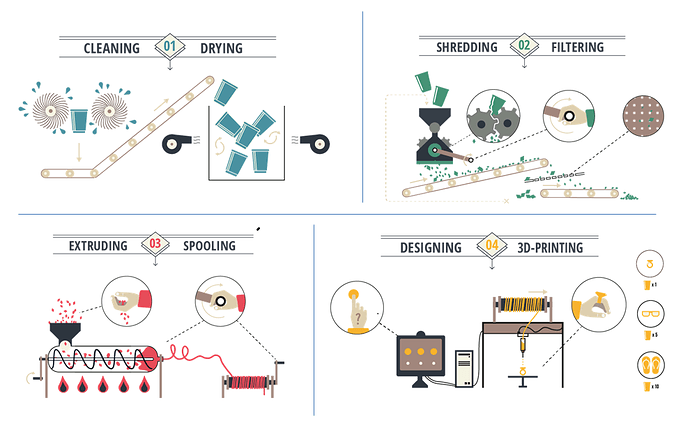

In the first 53and second 53 post of this series I looked into the different reasons for making your own recycled filament and what the process to do this looks like. Now that we know that we want to recycle and what the process looks like let’s take a look at the different machines that are available to do this.

The recycling process (source: Better Future Factory, design: Studio Dolour)

Especially for extruding there are already many different machines available ranging from very basic to industrial grade machines. This overview is meant to show what is currently on the market and to guide a first scan of machines that might be suitable to your needs.

Shredders:

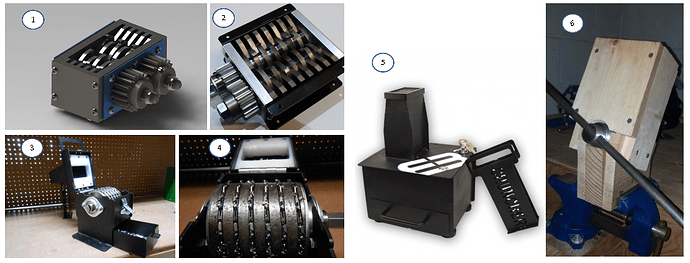

1&2 The Filamaker shredders 834

German programmer and inventor Marcus Senicky has invented a shredder that is specifically designed for tearing up your old prints. It comes in a small (1) and a larger (2) size for €370 and €550 respectively. Check it out hard at work 272.

3&4 The Filabot Reclaimer: 673

This is a shredder made by Filabot that is expected to be available for sale at the end of this year.

This shredder produced by the makers of the Extrusionbot has just launched its kickstarter campaign. $485 will get you the basic package which is claimed to be way below the retail price that will be used once the project is backed.

For the more adventurous and skillful people out there there is also the possibility to make your own shredder using this 661 DIY guide on instructables.com 218. It claims to be more simple and cheap than the other options on the market so it might just be worth your while.

Of course you can also try using any other machine that can shred plastic into smaller pieces. For instance using a normal office shredder or an industrial shredder might work. I don’t have any experience with this but if you do please share in the comments!

- Extruders:

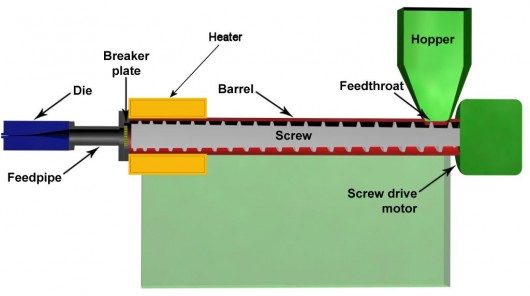

Most extruders work in pretty much the same way. A screw pushes the plastic pieces through a heated area where the plastic is melted. The liquid plastic is then extruded through a nozzle. This is roughly what your average extruder such as the Filabot would look like if you cut it in half:

Check out what this looks like in motion in this short animation 108. In case your up for a more in depth and seriously '80-ies style explanation check out this video. 29

Now let’s get to the overview of the different extruders that are currently available. We have only been able to test the Filabot 251 extruder here at our HQ which works great. There is a rather wide range in pricing but there might also be significant differences in quality of the different extruders but unfortunately at this point we can’t say much about that so I’d like to invite you to share your experiences in the comments. If I’ve missed one please post it in the comments as well so I can add it to this post.

- Strooder 1.1k | on sale for $249

- Filastruder kit 603 | on sale for $300

- STRUdittle 298 | on kickstarter | starter pack for $300 full package for $500

- Lyman filament extruder 174 | DIY project | costs of material approximately $600

- Extrusionbot 213 | on kickstarter | starter kit for home assembly $365 full package $675

- Protocycler 264 | Combined shredder and extruder | pre-order for $699 (expected shipment fall 2015)

- Filafab pro 100 171 | Easy assembly | on sale for $749

- Noztek Pro 127 | on sale for $749

- Filabot original 251 | on sale for $949. Get itwith a nice discount through the 3D Hubs perks program 251

- Recyclebot 240 | Reprap project | electrical components can be bought for +/- $800

For a more elaborate overview of what’s on the market I highly recommend reading this post 71 on the different machines that are currently available.

What’s next?

This is the first of 5 series of posts meant to cover the topic of recycling for 3D printing. The next 4 series will dive deeper into the world of recycling and will focus on:

Series 2 | How to make your own filament by recycling old 3D prints

Series 3 | 3D Printing with recycled filament

Series 4 | The promise of 3D printing with recycled household waste

Series 5 | Can Polypropylene (PP) plastic be the next big thing in 3D Printing

However I’m very eager to hear what research area’s you would like me to research as well!

That’s it for now.

Cheers,

Bram

created

Jul '15last reply

Sep '15- 21

replies

- 29.0k

views

- 12

users

- 30

likes

- 21

links