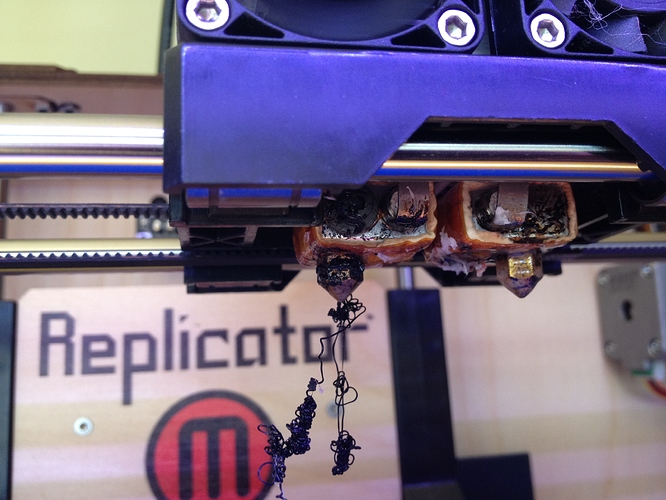

For anybody that’s a 3D printing enthusiast, you’ve more than likely ran into a clog or two - especially on those long prints that need to be done on time. I have a few tried and tested methods of my own to stop / fix clogs and have researched a few others. Here’s a compilation of the research that I’ve done and some tips and tricks along the way. As always, please feel free to add more in the comments ![]()

Preventative measures to stop clogging and jams

The best way to fix clogs and jams is to fix them before they actually happen. Here are a few things to pay attention to in regards to that.

Switching Filaments

When you are switching filaments a lot, there’s a higher probability of jams. Not all filament is created equal and sometimes those diameters or other properties are slightly off. Also, different filament requires different settings. When you are changing filament and settings, there’s usually some residual material left during the change. If you can, have a few go to filaments that you know work and stick with that. However, experimenting is fun. If possible, try and keep filament types standardized with the 3D printers you are playing with (this assumes you have more than one 3D printer). Alternatively, read on to see how to fix the jams when they happen.

Quality Filament

Don’t be surprised when that $20 filament doesn’t print too well. The cheaper filament tends to lack any sort of quality control. Do your research when purchasing filament!

Filament Storage

Ambient moisture get absorbed in PLA and a lot of other common thermoplastics that are 3D printed material. I would recommend storing your filament in a ziplock bag with a small thing of Cat litter or desiccant ( any moisture absorbers will work). I then keep it in a big tupperware container. It’s a little bit of overkill, but better safe than sorry.

Proper Temperature

Refer to the material page that has temperature best practices - These are available on most 3D printing filament manufacturers websites. You can have some variance here, but stay within the range for most use cases.

Hotends

If you are looking to experiment with more exotic material that requires higher printing temparature, an all metal hot end is a must. I’ve heard very good things about the E3D or Prometheus. I’d also recommend getting a 3mm nozzle. Once properly dialed in, a 3mm nozzle prints very well. Since there are more ‘particles’ in the exotic filaments, the 3mm nozzle prints them a bit smoother.

Canola Oil

Don’t laugh, apparently this works. Put a small amount on your fingertip and wipe it on the start of your filament spool prior to printing. Apply this sparingly, you don’t really need too much and it will was a long time. Basically, the oil is acting as a lubricant in the heat chamber. If anybody has more details on the science behind, I’d love to learn more.

My Extruder still jammed - now what?

No worries! There are methods to get rid of the jam, it’s just slightly more difficult. I try and avoid disassembly with these methods - I’ve broken a few hot ends by not applying the right amount of torque and putting things back together is less fun than taking things apart. Refer to your manual if the method recommends removing parts.

“Assist” Method

Once clogged and not printing, ramp up the heat a couple of degrees and manually force the filament through. Check the flow of the filament - if its not being pushed to the side, then it should be fine.

Modified Tooth Pick Method

Grab a tooth pick and print yourself this Thingiverse project 348. This can be used to quickly clear most filament clogs. Follow the instructions on the thingiverse page - its fairly straight forward and doesn’t require disassembly.

Guitar String Method

Get a guitar string that matches your nozzle diameter. Push it through while its heated. This can work if the clog is not very bad, but oftentimes it does not get the hard to reach places on the nozzle.

Torch or lighter Method

Slightly dangerous, but does work. Use a torch or flame to heat the nozzle. Use your own discretion, but I recommend removing the nozzle first. Can also damage other equipment, so I would avoid this method if possible.

Acetone Wash

This method requires disassembly. Essentially, remove the nozzle (easier said than done) and put it in a small cup of Acetone. Clear some of the hard to reach places out with a toothpick. Let it sit overnight. Be sure to do this in an open area, you don’t want to inhale too much Acetone fumes. This method definitely works, but depending on the extruder you have, removing the nozzle is not always straight forward.

That’s about all I can think of. If you’re printing a lot, its not a bad idea to have some spare extruders lying around for easy swapping. Like most things 3D Printing, tinkering is required and encouraged. What is everyone else’s tips and tricks for preventing and fixing filament clogs?

created

Mar '15last reply

Aug '18- 23

replies

- 11.5k

views

- 17

users

- 24

likes

- 6

links