I bought me a Duplicator i3 Plus. Brought it home, leveled (poorly) then printed the unicorn. It came out beautifully. Then I read the rest of the manual, watched videos, read some of your posts and in other forums. Printed the vase, downloaded and sliced/printed stuff off of Thingiverse, modeled (all by myself!) a torus with writing on the outside, sliced and printed it fine. Look at me! I’m a happy 3D printer owner!

Then something happened. I don’t know what. The extruder and the bed are alternately ganging up on me - mostly the extruder. It doesn’t extrude straight and things don’t stick. I thought I may have printed something too closely (it left an gouge of outline on the bed). So I thought I must have damaged the nozzle. I replaced the scored bed (first with the extra bed cover, then with 1/8" glass). I think that eliminated the bed problem - esp after fixing a slight tilt in the Z-rails.

Nothing I do is working. All those successful prints when I didn’t know what I was doing - now I think I know more and I can’t even print that M3 thumbwheel. I’m ready to throw the thing out the window (not that that will damage it - I’m in the basement and the ground is 6" below my window). I have faith. You will see what I’m doing wrong and tell me and life will be good again.

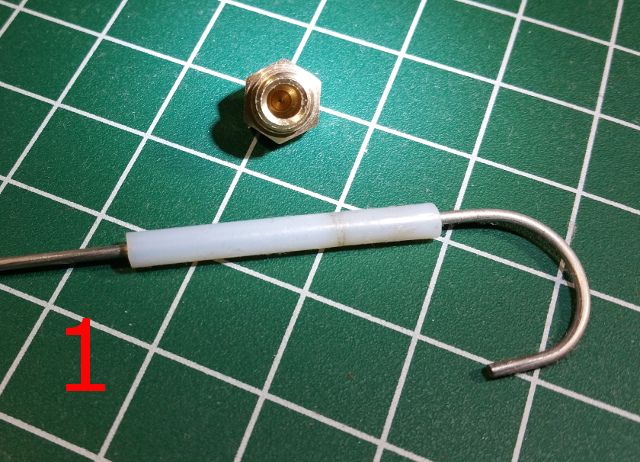

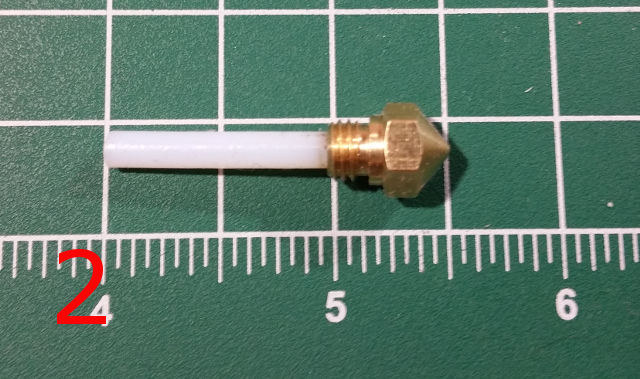

I bought some new nozzles and tried the following (each number corresponds to a picture):

- Brand spanking new nozzle. The old plastic throat thing, but clear of obstructions.

- Insert the plastic throat thing into the nozzle all the way.

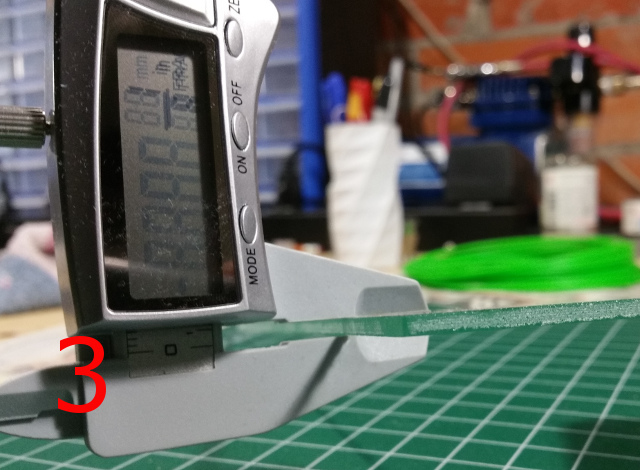

- Cut a sheet of 1/8" thick glass to fit. Just plain old glass that used to be in my buddy’s window before the baseball incident. Cleaned it with rubbing alcohol until it squeaked.

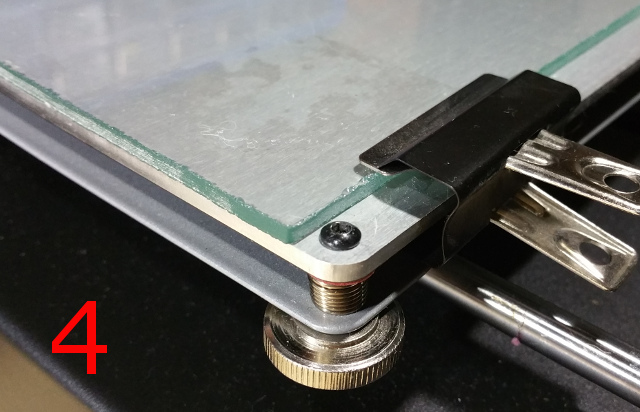

- Put in on the nicely cleaned aluminum bed with clips (I had previously tried thermal silicone, but it didn’t keep the glass immobile). I adjusted the clips after this pic to ensure they didn’t get in the way of the print head during levelling.

- Preheated to ABS temps, then using a 0.40 mm thick business card, I leveled the bed with the built-in auto-leveller. Then I leveled it again. Did this until I went through the auto-level steps without making an adjustment. The way I did it is to place the card where the nozzle will go before the nozzle moved. Then I moved the card back and forth, narrowing the gap until the nozzle stopped the card. Then widened the gap until I could just feel the nozzle against the card as I moved it back and forth. Repeat for each of the five stops the nozzle makes.

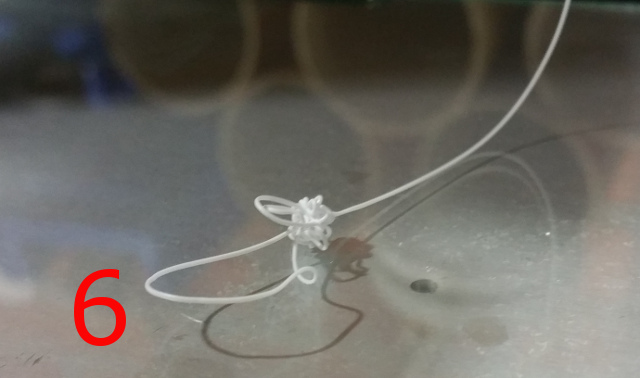

- Then I loaded the filament using the “Load filament” button. The filament came out in loops at first, then eventually started coming out straight. I didn’t catch it with the camera in time. You seen in this picture the loops that used to be bunched up directly under the nozzle - now at the end of a long filament. When this happens it’s as if the filament defies gravity. “I’m going down? Nope, lemme just turn around and go back up.”

- Before trying a print, I checked the bed temperature. I’ve heard the glass makes it not warm up as much. With the LCD telling me the bed temp is 54°C, my thermometer tells me the glass is just under 51°. I’ve checked at different temperatures and the bed is consistently 3-4° cooler than the LCD thinks it is. I think this is okay.

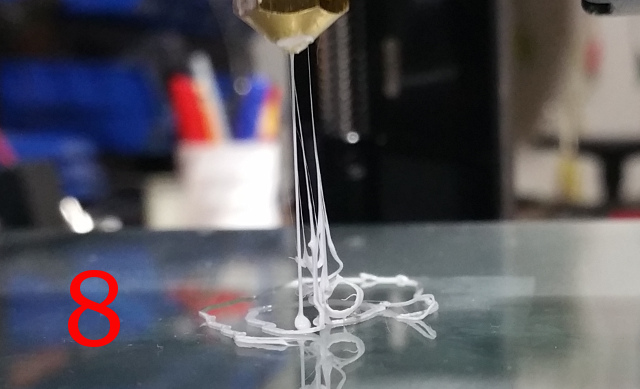

- Started a print, and blammo - happened again. The filament loops a bit, giving something to catch on until very quickly I get something like this picture.

If a picture is worth a thousand words, how much is a video? Well, I’ve got three:

- After laying down a few passes in the brim, it immediately bungles up when trying to print the actual thing.

Extruder problems vid1 - YouTube 41 - By the time I hit it, the ooze has climbed back up and attached to the nozzle. I didn’t notice before I hit [+] E to extrude a bit. Kinda pretty, but definitely not helping print what I want.

- YouTube - Another attempted print. You’ll see me clear away a bit of ooze before the print starts. In the brief time after that and before the print starts, you can see a tiny loop form - dooming the print.

Extruder problems vid3 - YouTube 14

What am I doing wrong? I’ve tried thinner and thicker cards to level with smaller and larger gaps. I’ve checked the Z-axis rails. I didn’t do any of this for my first several prints - they were easy and hassle free. Now, nothing I do results in a successful print.

Help!

created

May '17last reply

Mar '19- 29

replies

- 8.6k

views

- 14

users

- 1

like

- 5

links

Also, I wasn’t clear in the OP, but I’m using PLA.

Also, I wasn’t clear in the OP, but I’m using PLA.