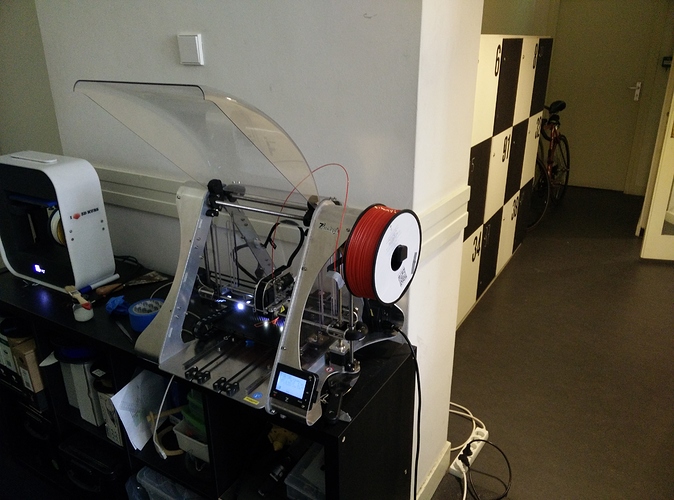

Today I’m trying to print some parts on the Zmorph here at the 3D Hubs HQ.

Although this is a super user friendly machine with loads of options I haven’t been able to get the settings right to counter warping. I’ve already applied a liquid to the platform that contains ABS dissolved in aceton that was delivered with the Zmorph. This has definitely had some effect but the problem is not solved. I’m printing a beam so this might not be the most ideal design to print either.

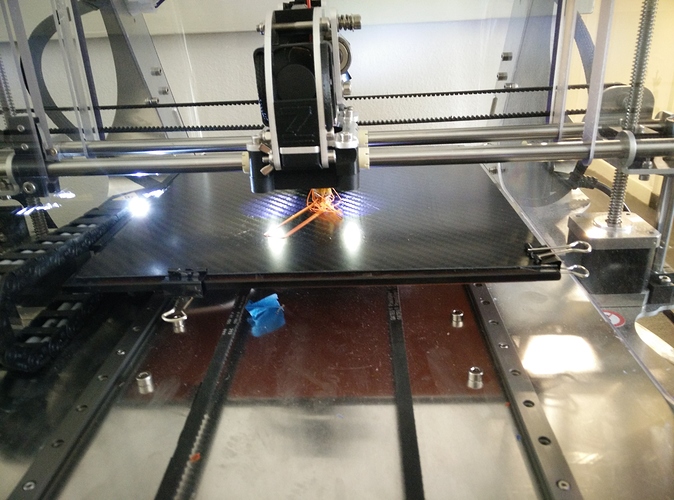

As soon as a couple of layers are printed the warping starts and the print needs to be stopped.

The settings that I’ve tried are:

- Print temp: 245C

- Heated bed temp: 100C

- Layer height: 0,2mm

- Support types: power raft ABS, brim and box

- 50% infill

Does anyone know good print settings or another similar design that has less problems warping? Thanks!

2 Likes

Hey @bramhallo , Could you show the model that you are trying to print and maybe share the settings that you have tried already?

Hi bramhallo,

my first guess would be that the print bed is not calibrated correctly. If the first layer is not ‘squeezed’ on the build plate evenly, it will start warping already after a few layers.

Also, I’m guessing there is a huge fan on the extruder (can’t really tell from the picture). I suggest you switch it off or reduce its speed. Too rapid cooling will increase warping. I even disable cooling completely and enclose my entire build volume so the part stays warm.

The beam should not be a problem to print in ABS. If you keep struggling, I suggest to reduce the infill (more infill increases stress) or to print your beam upright instead of flat.

Finally, I recommend using 3D-Lac instead of acetone-ABS mix. It’s much more user friendly and after printing, when the build plate is cooled down, the part will simply pop off.

I never use a raft or brim when printing ABS. Unless you’re printing really big parts, this should not be necessary to prevent warping.

Hope this helps!

1 Like

Hi bramhallo,

We recommend removing this carbon fiber pad from the bed. We don’t know this material so we can’t help you with sticking prints to that. One of the solution may be increasing hot bed temperature. It is possible that the pad might cause thermal isolation and the temperature of surface is not reached. Instead of this we suggest printing on the glass. If you have a problem with that check out our article. http://zmorph3d.com/print-bed-adhesion/

Let me know if it works:)

Best regards,

Arek from Zmorph Team

2 Likes

Good one! I’ve added them to this post

Hi Pieter,

Thanks for helping me out! Some very usefull comments. I’ll try again today using your tips and will get back on the progress.

Cheers,

Bram

Hi Arek,

Thanks for your comment! I will try printing directly on the glass today. Will let you know how it goes.

Cheers,

Bram

Hi Arek,

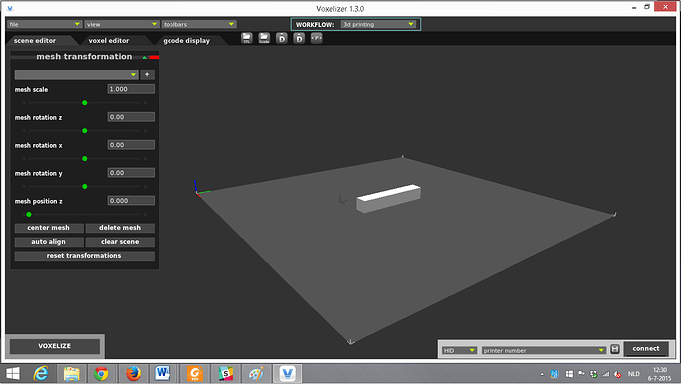

I’ve been experimenting with the Zmorph quite a bit last week and today but I haven’t been able to get any results because the ABS filament isn’t sticking to the bed. I’ve had some issues calibrating the Zmorph but I’m quite sure that I’ve got that fixed since a paper can barely move underneath it in all areas of the glass plate and the calibration tool gives the result as shown in attached picture.

I’ve had the heated bed constant at 100C. I’ve tried the glass plate, the aceton-ABS mix and blue tape. I’ve taken care of all other precautions in the link you sent as well.

When flushing the nozzles this goes perfectly fine but when extruding onto the platform very little filament seems to come out and this filament doesn’t stick to the plate but is most of the time curling up in knits behind the extruder. Do you know what might be the issue and how to solve this? Thanks a lot in any case for your help!

Cheers,

Bram

This thread is a few months old already but I wanted to document my recent experiences with ABS on the Zmorph. I’m printing 1.75mm Hatchbox ABS purchased through Anazon, using the 245C / 100C temperatures (nozzle / bed). My best prints have used rafts on glass. When I remove the raft, I find that calibrating the glass flatness and optimizing the filament extrusion speed is critical to getting parts that don’t warp as much. Also - any parts with cross sections thicker than 1.5 cm with thin aspect ratios (long and thin and thick) will warp no matter what, even if I crank up the bed temperature. I can usually tell by the opacity of the printed layers of warping will occur. Layers that are translucent usually do not warp - if I see the plastic going cloudy I know the part will be twisting up off the glass soon.

My answer to ABS’s persnickety properties? I switched to PETG. The same troublesome parts in ABS print like a dream in PETG (poly(ethylene terephthalate) - glycol modified) - with no warping that I can see so far. I’m running at same conditions as ABS and I can print directly on glass with no tape, kapton or ABS juice. PETG has the toughness of nylon with the ease of printing PLA. Give it a try and you may leave ABS behind.

1 Like