Hi, last week we had problems in the result of parts, but later it worked ok.

Today it was printing ok, and suddenly received a stop and message of Vaccum pump out of range (or similar) Now it does not work. Vaccum Value is 1.0 instead of 6.0. Support Block appears “empty” on screen, and there is some resin on tray. Now I see Model Head leaks and the Printer is off!

Please help! Any comment is welcome! I was planning to run shutdown wizard next week because local holiday.

Best,

FabbIt

2

Hello,

i had a simular problem with my prime.

Please check if there is any material in the tube from the head to the pump.

There should be an transparent tube going from the Back of the Head all the way down in the back of the machine.

Its between the support and Material tube.

You can unscrew it to check.

If there is ametrial in it please come Back and post again.

I will show you how to change the tube (normaly it hardens inside the tube) and to setup your Pump again.

This problem comes from not switching off your machine while waittimes over 48 hours.

If the material arrives your pump it will be defect! I managed to clean it out and get it to work again. But thats a lot of work and hard to do.

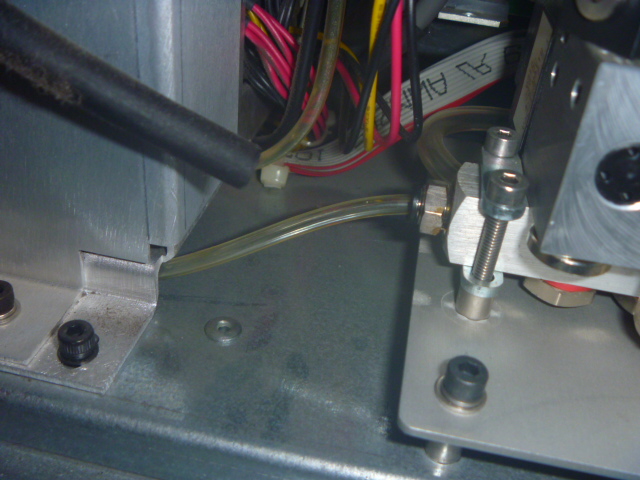

Attached is a picture of the vacuum tube.

In this shouldn´t be any material!

1 Like

Fcanaan

3

You.may want to run the SHR wizard and check the seals on the heads. If you are under a maintenance contract you may want to contact support first. This may void your warranty or piss off your service tech…

You are probably going to have to call Stratasys and either hope they will walk you through your problem or they are going to send a technician. I operate an Objet Eden at work but admittedly I am not very intimately versed in the details of how the system works. I do know that there is a sensor board for the vacuum system. They sent us a replacement one in one of our uptime kits. So this may be an item known to fail. Otherwise your pump or the tubing has possibly failed. I believe this vacuum line runs up to the small tray by the roller and roller blade to pull waste out of it. Which is why you are seeing material spill on the build tray. Clean the roller tray and start tracing the vacuum line back.

Hello,

We already called stratasys tech, but we are 700km from them and they won’t be able to come until October…

So here is the pic of vaccum tube and unfortunatelly there is material in it. Following the line, it doesn’t get to the pump in the front of the machine (it almost did, but now it is clean, see pic)

Now the printer is off, and I can’t run flush to let it off until october. I don’t know what to do…

You need to clean the vacuum tube going from head to the vacuum pump assembly. You may also clean the assembly itself, or replace the valves (just in case it’s impossible to clean). The problem usually comes from a clogged material or support material filter. It can also come from a clogged head: you need to print several times per week (even a small part), and also wipe the heads everyday with this technology.

1 Like

Clean the tube again and remove the heads and clean them also, with pure IPA (no water mix). You can unclog the heads by using a syringe and force IPA through the nozzles: you have two holes and you need to close the other one with your finger. Use goggles and gloves!

Hello, thanks for your help! Can you help me with the process? Do I need any particular tool or device? Or just “unplug” the transparent tube from Head and pump? what should I use to empty de tube? pressured air? In our city we don’t have the spare parts from Humphrey Valves (I don’t know what models should I seek)

Hope you can help me,

Best!

Flush with IPA and then dry it with compressed air.

Can you send me photos please???

Thanks!

Can you send me photos please???

Any recomendations when detaching tubes? Will I need to seal when assembing again?

Thanks!

FabbIt

12

It looks like the Material doesn´t reached your Pump (lucky You).

Its not deep inside the tube.Unplug both ends and use a wire to loosen the harden Part of resin in there.

The Blow Air from the other side (vacuumpump side) in it and it will clean out.

At last you flush the tube manual with alcohol and dry it with air.

If you need a Tutorial on that or photos let me know

a.roser@fabb-it.com

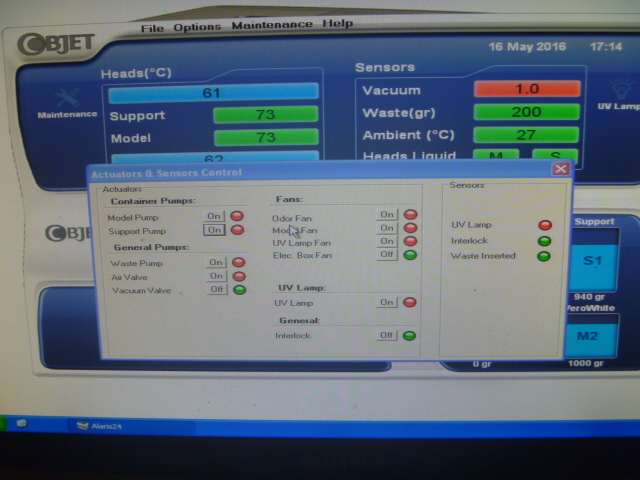

Finally tube from head to pump was clenaed out and empty (only air). Turned on again, but pressure keep low in 0.9. So we tested pumps and valves from “maintenance > actuators & sensors control”. It all seems to work ok. You can see model and support pump spin in the back. And Tac is heard when turning on waste pump and air and vaccum Valves. But the bad thing is that when turning on support pump, liquid begins to flow through transparent tube.!!

Any suggestions?? Thanks

L2D_TW

14

Hello everyone,

Is this problem be solved?

My objet has the same problem, it just happen today.

Looking for a new THOMAS 30030533-4V Vacuum pump now.

I have to check my objet 30 and to clean the head every hour.

So sad.

Jay

Hi Jay, I solved it applying WD40 in the axis a couple of days, ans it got back to spin normally and get the 6.0 pressure. They do not sell this spare part as far as I know

1 Like

L2D_TW

16

Hi protoserie,

Sorry for reply late, I didn’t got the notification, or I close it - will check it later.

So far, what I done is to shutdown my Objet and clean the print head continuously, until the material and support not dropping.

I didn’t clean the vacuum tube from head to pump, not yet.

And the pump company - Gardner Denver - just like you say, THOMAS 30030533-4V is special OEM part for selling to Stratasys only.

So, back to what you say…

Can you tell me or show me some images, which axis is need to spay WD40 a couple of days?

It will be very helpful to me.

Thanks again for your kind reply, and have a nice weekend.

Best,

Jay

L2D_TW

17

Hello protoserie,

Do you mean the axis of this tiny vacuum pump?

Best,

Jay

L2D_TW

19

Thanks @protoserie

Finally, the pump back to work.

I wrote down these steps and take some pictures on my blog.

but it seems that I can not allow to left link here.

goo.gl/ydRi5a

I would like to share with someone who need this.

Thanks a lot.

Best,

Jay

L2D_TW

20

Hi everyone,

So far, we can use WD-40 or something similar to let it back to work, but just in case if someone need to replace this miniature / micro drive “THOMAS 30030533-4V”, someday…

You can contact “FAULHABER”, which is the company producing this micro-motor, as you can check on the bottom information of THOMAS pump.

“FAULHABER”

“1525T012BRC”

“XY3306”

“1214”

attachment is the PDF of FAULHABER, check the last page (P.69) then you can find the information.

They should have worldwide reseller.

And it’s not that EXPENSIVE as THOMAS.

Good luck!

Jay

technical_information.pdf (4.01 MB)