I downloaded cura and think you get a lot more control with repetier. I did not give it a fair chance though. Im getting some good results with my 0.3 mm head. I adjusted the layer height to 2.4 mm and that seemed to do the trick. The undercuts and curved bridging is still an issue but not as noticeable as before.

Cura is a bit more user friendly than Repetier. It provides a good belance between easy printing and configurability. Good to hear the PrintrBot produces acceptable results again.

Check the PrintrBot talk forum if you run into some issues in the future. It contains lots of expert users, information related to troubleshooting your PrintrBot and expert tips to finetune to print on 100 micron or less

Ken

Type M501 into Repetier-Host and check what it returns for M92. Your steps/mm should be 80.00 for X and Y, 2020.00 for Z, and 96.00 for E on the Printrbot Simple Metal. This will ensure that your dimensions and extrusion rates are accurate, assuming you’ve entered an accurate filament diameter in your slicer (1.75 or close to it, if you measured your filament with calipers). Are you using the stock 0.4mm nozzle? It should work fine for anywhere between 25 micron to 320 micron layer heights.

One thing i cannot reccomend more is to callibrate your z probe and keep it tight. And callibrate it down to a hundreth of a mm. Also try using a raft. And for the extrustion multiplier i wouldnt change it but change the steps per mm val which is shown on thomas sanladerers youtube channel. Also my ubis hot end never skips you may have a clogged nozzle which i have had before thats the only time my printer has skipped steps. it also may be if you are printing too cold i print at 200 c for pla.

have an early 2013 printrbot simple. i use to print cubes to calibrate to the detail the axis, check the tension of the belts, and make a good control of the temperatures of the filament. I passed the test at fist try, and i think is because i tried many filaments before. I use PLA at 210ºC first layers and switch to 205 after. This model requires 100%fan al the time. my max speed is 60mm/s even 50mm/ ti aassure the printinh have enough time to get cold between layers. usinic3r, but the last version. The bad part of your side is motor skipping steps, i think. and the cooling

Good luck

Yeah, from what I understand Repetier has a lot more fine-tuning options. I’m planning on trying it at some point, but for now Cura is working for what I need it to do. I’m glad you got this working, your print is looking good.

Try running at a higher temperature at a lower speed of under 30. Tighten the extruder and try it again

sorry to hear it. I too am struggling with printrbot settings First layer printing problems - YouTube

Hey Patrick. It does look like your z offset may need to be adjusted a little lower, however I expect that the majority of your adhesion issues are due to your bed prep. What type of blue tape are you using, and how did you prepare it for printing? Painters tape is coated with a wax, which helps its primary function for masking paint edges. It makes a lousy surface for hot plastic to stick to, though. It’s important to remove this coating before trying to print. Some say that the brand of tape makes a difference - I can’t say for certain because I’ve only used Scotch 2090 since it was confirmed to be good. You also need to wipe down the tape with alcohol before printing to remove the wax and any other oils or contaminants. Most people use isopropyl alcohol, I use denatured alcohol from the hardware store just because I had that on hand but no isopropyl when I started printing.

Scotch 2090 tape is very easy to find, although it will cost a bit more than store brands. It’s the one with a white stripe on the packaging and says “general use” or “multi-use” (I can’t remember for certain.) It will say Scotch 2090 on inside roll, but I think it’s also listed on the outer wrapper as well. I use the widest roll I can find, it technically costs a little more per square inch but it’s a lot quicker and easier to lay down and I have less seams.

I hope this helps, if you still have trouble let me know.

Thanks, I had not heard about the wax and alcohol. I am using 2090 3m scotch tape and freeze hold hair spray.

Try without the hairspray as well. I’ve never used it with blue tape, it’s my understanding that it’s used with a bare metal bed. I’m not sure if it’s good at getting a better release when printing is complete, I often have trouble getting my prints off the bed without marring the tape and having to put down a replacement strip.

My secret for the PrintrBot Simple Metal without heated bed was: kapton tape on the metal bed combined with woodglue (PVA + 50% water). A slight layer of that PVA mixed with water did the trick creating a nice first layer adhesion between the print and the kapton tape. It prevented almost all warping effects and also created a smooth bottom surface as if it was printed on glass.

Repetier may give you more dials, but it’s moot if you don’t know which way to turn them.

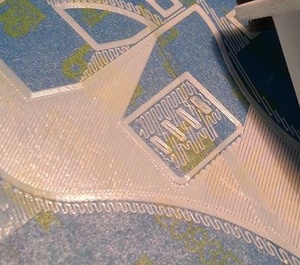

Marvin in 3D Solutech “Real Silver” sliced with Cura 15 and printed on the stock Printrbot Simple Metal heated bed model 1403 with thing:356001 and thing:607836 upgrades; printed at 0.09525 layer height (all layers), 187C, 15mmps, 4-shells, 30% infill, 40mmps travel, 0.98 extrusion multiplier (on calibrated extruder), 100% fan @ 0.2mm, PVA (Uhu) over PET on 0C bed in far-left corner with 25mm diam, 2-shells “cooling” cylinder printed in close-right corner:

https://www.3dhubs.com/san-francisco/hubs/fiveangle-same-day/

this is amazing; all the little support material is right where it is supposed to be.

wow, I wiped the bed with alcohol and it’s super sticky! Thanks who suggested that.

What filament did you use for the shiny marvins on the right? Do you have more pictures of stuff printed with that?

Its the same filament as the other picture, but at 200 micron. has a satin look.

I would use a layer height of .2064 and a base layer height of .254 this is the reccomended layer height using the 3/8 lead screw according to the prusa calculator and printrbot. Also try slowing down your print i had luck printing marvin at 30 mm/s and also adjust your z offset to the hundreth of a mm and use a raft when printing small intricate objects.

What is it called?

fiveangle, thanks for the details here. Have you ever printed Marvin with ABS at 0.1mm?

What settings would you use for ABS?

I assume that your “cooling cylinder” is a second model which you are printing to move the hot end away from the primary print to allow each layer to cool. What retraction settings do you use when doing this?

I have attempted to print Marvin with Yellow PLA and Black ABS on my Printrbot Simple 1403

The PLA print came out nice, but I am still having trouble with ABS.

I have images posted on my hub page:

https://www.3dhubs.com/montgomery/hubs/craig

Thanks