Hi there! I’m Bram and I’ve been stretching the shredding, extruding and printing machines to the limits here at our 3D Hubs HQ. After a lot of experimenting now it’s time to show the results of some serious printing with recycled filament. A sneak peak, this is what your homemade fully recycled PLA prints could look like:

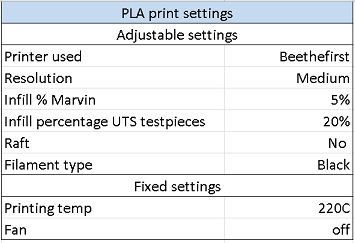

PLA is in general regarded to be more ‘easy’ to print with than ABS. With the strings of filament that I produced I definitely had this experience since printing PLA went super smooth whereas printing ABS took quite a while to figure out. For printing the PLA filament samples I used a Beethefirst printer by the @Beeverycreative company. This printer is very user friendly and produces very constant and good looking prints. Recently an update of the software for the Beethefirst came out that allows you to import and export Gcode files. However at the time I made the prints this was not yet the case so only a few of the settings could be altered.

(Print settings Beethefirst printer)

I printed with filament samples that I made using a @Filabot extruder. To produce each sample I used a different mix of recycled old prints and new pellets as input material. If you would like to see the way in which I made the different recycled filament samples check out post 1 and post 2 from my previous series.

These are the PLA filament samples that I made:

- New filament

- 100% Pellets

- 75% Pellets 25% Recycled prints

- 50% Pellets 50% Recycled prints

- 25% Pellets 75% Recycled prints

- 100% Recycled prints

Using the Beethefirst printer I turned each filament sample into a Marvin and into 3 pieces to test the strength of the material. The pellets were blue and the recycled old prints were white and as you can see from Marvins different tints both of these materials mixed very nicely.

(From left to right: new filament, 100% pellets, 75%pellets, 50% pellets, 25% pellets, 100% recycled material)

The Marvins turned out great and to be honest I was surprised by the quality of the prints but even more so by the very small differences between the different prints. The higher the percentage of recycled material in the mix is the rougher the surface of Marvin looks. Apart from this there seem to be no real differences between the Marvins. At least not ones that can be seen by eye. Furthermore all Marvins needed only one cycle to be printed.

To see the difference between fully recycled and completely new filament I printed two Marvins that used the same original filament. One of them (on the right) had been recycled with the Filabot already once and the other one (on the left) is brand new.

(Left Marvin: 1st cycle, Right Marvin: 2nd cycle)

As can be seen from the next picture the difference between a fully recycled Marvin and a Marvin printed with filament from 100% new pellets isn’t that big either.

(Marvin left: 100% pellets, Marvin right: 100% recycled)

Quantitative results

For each filament I printed three pieces that are designed to test the strength of the piece.

Using an Ultimate Tensile Strength (UTS) testing machine the strength of a material can be measured. The machine pulls on both ends of a part with a constant speed and measures the load that is applied:

(UTS testing machine)

A typical stress-strain curve for a test experiment would look like this:

You can see that the load is increased until a certain point after which the load evens out and starts to decrease. The maximum load is used to determine the UTS. After some analysis this figure shows the Ultimate Tensile Strength for the different experiments:

Experiments:

- 100% Pellets

- 75% Pellets 25% Recycled prints

- 50% Pellets 50% Recycled prints

- 25% Pellets 75% Recycled prints

- 100% Recycled prints

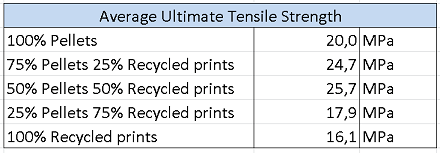

Based on these results the averages are the following:

Conclusions:

- Excellent printing results can be achieved when printing with filament that is produced by a Filabot.

- For visual quality of the prints there is little difference between fully recycled filament and filament made from new pellets. However the more recycled material is used the rougher the print is.

- The strength of printed parts is actually highest when using somewhere between 25% and 50% recycled material in combination with new pellets.

This is the third series of 5 on recycling for 3D printing. So far I’ve covered:

Series 1: Introduction to 3D printing recycling

Series 2:

Series 3 will be all about the results I’ve been able to achieve with my homemade filament.

- Post 1: Printing results for homemade PLA filament

- Post 2: Printing results for homemade ABS filament

In series 4 I will look into the promise of recycling your household waste into new filament and in series 5 I will put the plastic Polypropylene to the test to see how it holds up in this recycling process.

Stay tuned for some ABS info following soon!