I have to admit, ever since I’ve joined 3D Hubs as an Intern I’ve become addicted to 3D printing, talking about 3D printing and anything else related to it. When my Internship in the main office ended and I lost access to the printing Lab it was a little weird. Being back in Lithuania , telling everyone around me, going to the Tech fairs was the only thing that kept me breathing.

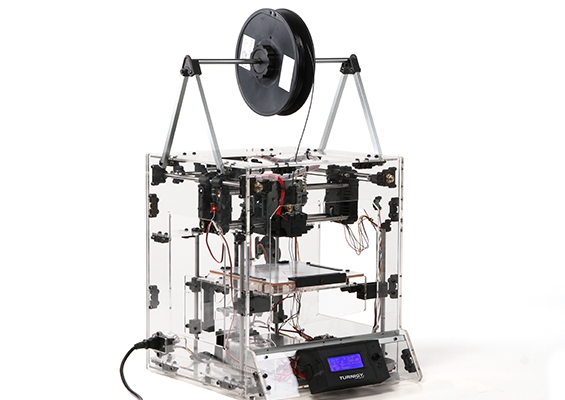

Having very limited resources I wanted to come back to the printing itself and I think I have found a pretty optimal solution. Enter: Turnigy fabricator

Buildsize: 150x150

Slicer: Cura

Price: ~400$

Nozzle: 0.4

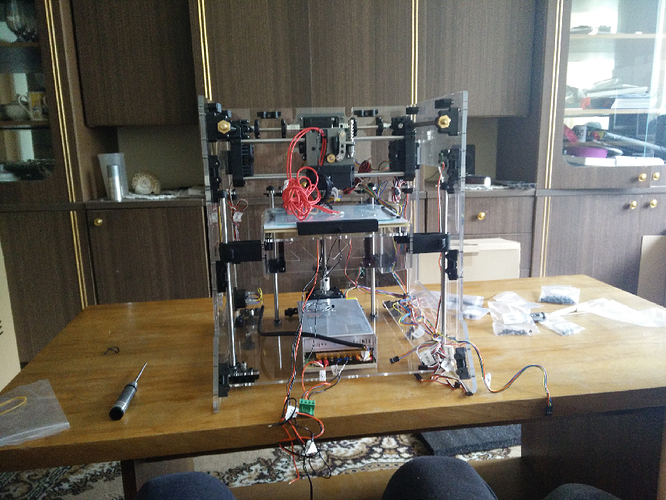

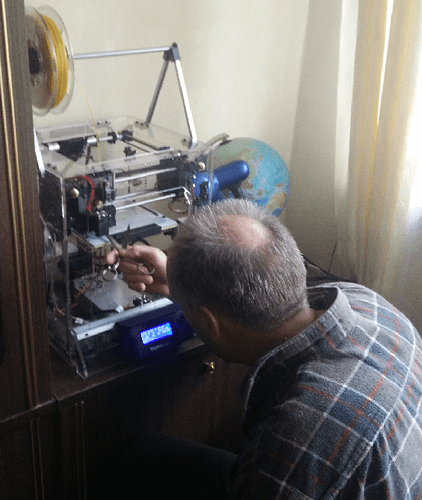

It’s a 3D printer kit and it’s cheap. Keep in mind that I have never built anything in my entire life so I was looking forward to the challenge of learning everything that a 3D printer contains.

Fortunately or not, everything was so simplified that the only resource which was needed was time. Everything up to the different little screws were labeled and put in many different boxes which were also labeled to make sure nothing gets lost.

As long as you follow the book (There is also the entire assembly process on YouTube as well), you’re good to go for sure. When my dad saw the way it was organized he said (and excuse my dad for this) : “Oh… this is for these dumb Americans”

In the end, I’ve got one spool of Filament to try out the printer and the first printed thing was obviously a Marvin. Here it is:

I’ll share the settings of this and my further Marvins in a next thread 4, but it was very very easy and so far I am very satisfied! Few things like the printer having no Filament feed-in function or being incompatible with the latest Cura version did suck, but I’ll get to that later.

I’ll make sure to share much more of what I do with this thing later on ![]()

p.s. In the end: My dad is even more excited about the printer than I am.

created

Oct '15last reply

Dec '16- 20

replies

- 3.8k

views

- 14

users

- 53

likes

- 1

link

Nice, one Arnie, I always liked your style!

Nice, one Arnie, I always liked your style!