Is there a way or place to post casting instructions for resin castable prints? Since these require a different ramping temps speeds and times, those of us who like to cast and have for years need this information so our resin casting come out the very best possible.

Toddmichael

3 Likes

Hey Todd,

If you’re interested in writing something up, I’m sure many people would find it very helpful. We are working creating more content and tutorials and casting is a very interesting subject. For now, the best place to put it would be on Talk. Let me know if you have any questions and I can help you out.

Alex

Hi Todd,

Have you allready check this out? http://formlabs.com/en/support/help/advanced/using-castable-resin/

Hope it will help!

Best,

L

Hey @Toddmichael, on this note, we’ve created a new channel for /Casting, so that all related content can gather in one place. How does this sound?

Hi Todd,

EnvisionTEC has a variety of instructional information available including casting and molding instructions for various materials. Here is the link:

http://envisiontec.com/jewelry-best-practices/

If you have further questions, feel free to contact us!

Jenna

Hi Todd,

We utilize a Form1+ and have experience with both the Formlabs Castable resin as well as with the MadeSolid FireCast resin. I’ve tested the thresholds for burning out both materials, at different time lengths with quick burnout processing at full temp with investments designed to do so, as well as from cold oven starts, pushing ramping times and soak times. Depending on ring size and the mass that’s being burned out, I find that both materials we’ve worked with burnout quite easily and cleanly, close to that of ash-free wax for jewelry or dental laboratory uses. I’ve actually had more of a difficult time getting beautiful ash-free burnouts from the 3D systems Visijet resins that utilize the paraffin wax for support material than I have had with either of these materials in the Form1+.

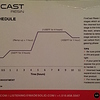

Additionally, I’d like to contribute the burnout specs for the MadeSolid FireCast resin for future referencing of other users here. The attached image is the card that comes with the FireCast resin when purchased.