Hello, nice to meet you all, I am new on this forum.

I bought a creatbot D600 last week, and I have a really hard time to make it work properly. I humbly require your help to resolve this mystery.

-The problem : As I do with every new printer I get, I try to print the 3Dbenchy 20, in PLA, with a 1.75 mm filament, and a 0.4 mm nozzle.

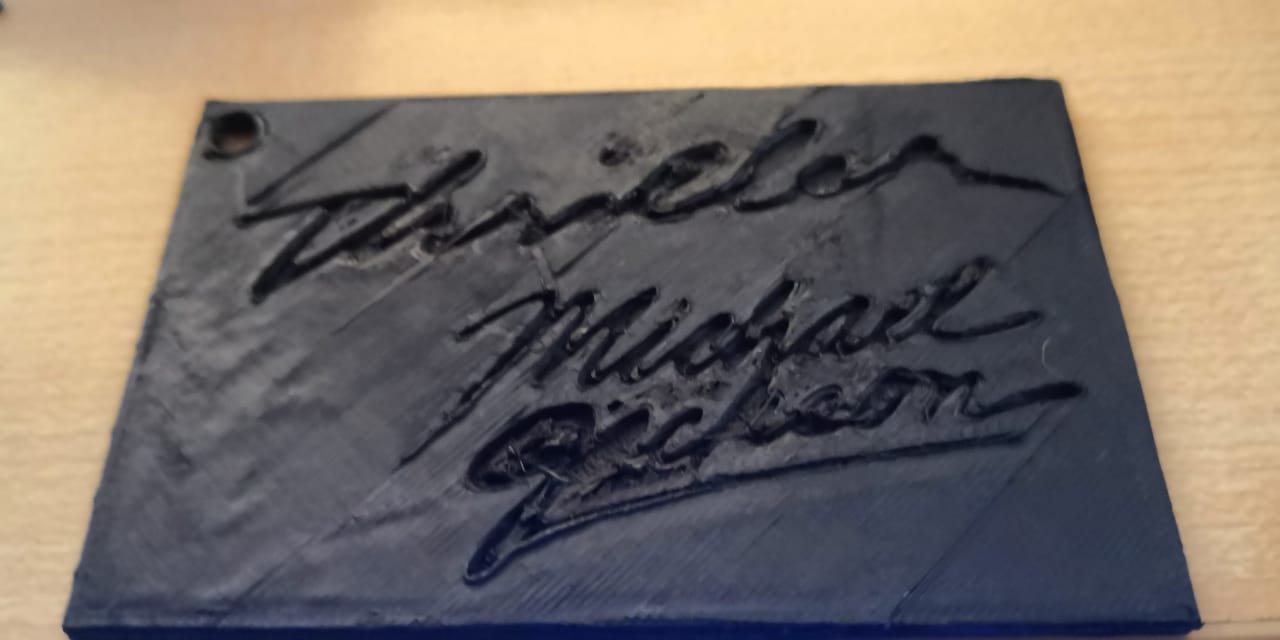

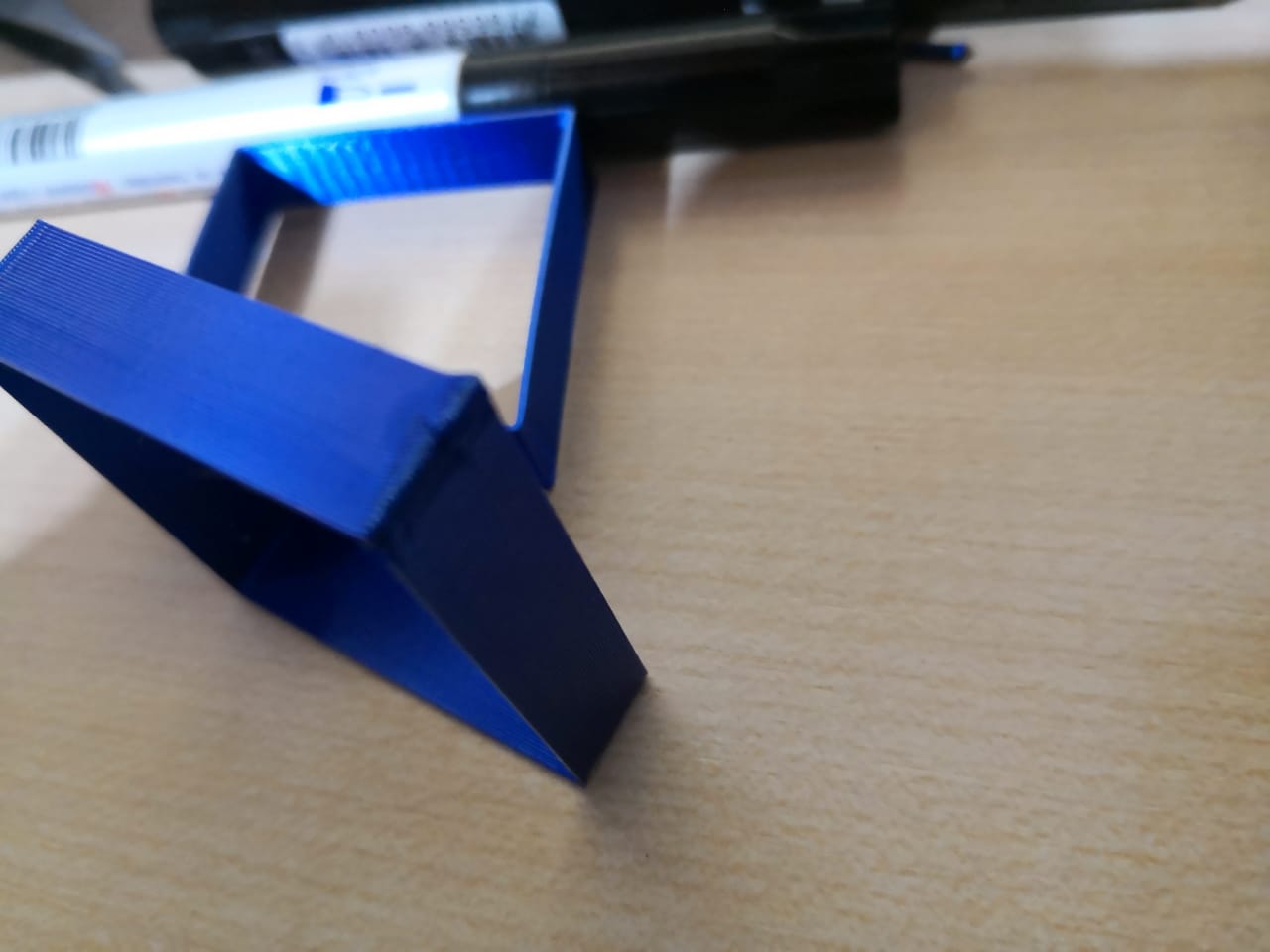

-The main issue is : at one moment during each print, the filament gets stuck in the nozzle, resulting in a quick underextrusion then no extrusion at all (pic n°1). When I remove the filament from the extruder, I can see it is gnawed by the filament feeder (pic n°2).

- What I tried :

I am in contact with a Creatbot engineer since the beginning, but his advices have been… unconclusive. I should have used creatware (the creatbot software, but the installer available online is infected with a malware… so if somebody has a clean up-to-date installer, I am interested), so I use the last version of cura, with custom printer.

Temperatures : I tried a range of extrusion temperatures from 210°C to 240°C.

Retractation: I put 1,5mm in the beginning, then removed completely retractation.

Speed : I tried 20 to 50 mm/sec.

Flow rate : 80% to 140 %

Compression nut : I tried to tighten it and untighten it.

Manual extrusion : No problem when I extrude the filament with the panel.

Shell : 0.8 mm

Top/bottom : 0.8mm.

Layer : 0.2 mm

Whatever the parameter, the result is similar. (sometimes, the filament is stuck even after the first layer).

I don’t know if you require more data. If so, just ask me. ![]()

I hope you can help me to solve my issue. Thank you for your time.

PS : Sorry if there are mistakes, english is not my native langage. ![]()

created

Apr '18last reply

Jun '19- 14

replies

- 9.9k

views

- 5

users

- 1

link