Buildplate temp you need to find the sweet spot…mine is at 110c now. Temp is also material dependant. If you use other material than the MB brand the temps vary bait too. Rafts and supports help with curling too. These are all design/print config items to think about. I even move stuff around on the buildplate, there may bee thermal differences on the plate as well. I use the clips too, makes for easy removal and cleaning.

Richard - for the glass…I looked into this before, do you place it on top of the existing bed? Also, how do you hold it in place and what thickness of glass do you use. I am a Kapton tape expert with no air bubbles but it very frustrating when I damage it removing parts! Cheers.

Anybody have a source for an Aluminum Extruder Block upgrade for a Rep 2X (I need left and right)? The place on eBay where I got them for my Rep 2 seems to have gone offline. If you have a better suggestion for the 2X I would love to hear your experiences.

This is the one I had wanted (scroll down on the listing)

http://www.ebay.com/itm/111566069212 29

Thanks!

For the past year I’ve been sticking prints well with Kapton tape from ebay and wiping the build plate every build with denatured alcohol. I’ve tried acetone without any benefit beyond alcohol, and acetone stinks anyway. the first couple tape application were stressful but now I have fine system that works great by having two pencils at two edges that I hold taunt during the process.

Based on info on the excellent (but now defunct) Makerbot Operators google group, I bought the Rep2 version of this http://devilsinthedetails.ca 31

It supports Rep2X too, I’m happy with it, although I’ve not managed to get ninjaflex to extrude yet, need to use the alternate spring I think.

Personally, I think it’s awesome, and well worth it, it does have some quirks and takes time to get settings ‘dialled’ in.

Being able to manually place support material in the GUI is a great feature.

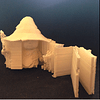

The automatic support material generation is kinda cool too; it kinds generates a concertina that can be easily removed(see attached)

The slicer is *fast*, it is multi-threaded so uses all your CPU cores.

Have you asked them directly? You might want to try.

Hi, where did you get the green panels from?

These are the upgrades I added to my Rep 2:

Aluminium X Ends: shop.raffle.ch 37

Aluminium Carriage: shop.raffle.ch 20

Aluminium Z Arm upgrade: BC Technological Solutions: Aluminum Arm 34

Aluminium 3-in-1 extruder: http://orders-3in1-extruder.davidheadrick.com 35

Heated Build Plate: BC Tech: Heated Build Plate 36

X-Axis cable RJ45 X-Cable Repair for Replicator 2/2X by whpthomas - Thingiverse 25

Power supply (because of HBP): https://www.meanwell-web.com/en/product-info/ac-dc-power-supply/adaptor/gt-200-w/gs220/product/GS220A24-R7B 10

This video of various Rep2/Rep2X upgrades is interesting, he’s done a lot with Replicators : https://www.youtube.com/watch?v=fvBLOmRXF0U&list=UUTh_cz1H9kqfxKAgaBZ38nQ 31

The attached guide also has some tips and nice exploded block diagrams. (I can’t find the original link, but the document is in the public domain)

Makerbot Replicator 2 Guide Public Edition.pdf 15 (1.23 MB)

While the article says you should level the build plate, I found that the out-of-the-box method is far from accurate. To get a truly level build plate, I haven’t found anything better than an incredibly thin leveling test print ( Leveling Test Print by DamianGto - Thingiverse 37 ) and a dial indicator rigged up on the X rails with some magnets ( Replicator Bed Level Jig by phineasjw - Thingiverse 28 )

Print once, find the point where the print came out the best, set that as your zero on your dial indicator, and then adjust the build plate until everywhere has the same reading. Repeat the process to either verify it’s level and set to the right height, or to find out how you might need to tweak the calibration, oooooorr… discover your build plate is warped in one corner and settle for not printing on that side until you get a glass build plate.

Amen on the test print for leveling. However my thingiverse print only 20 takes 2 minutes to print. Its set to only do hatching at corners and over each spring adjustments. Thing 80227 waste alot of material and time. Yes, I’ve found that the best leveling leaves the back left corner as an area to avoid. (or minimize with a raft)

Its the cooling personality of ABS that makes it warp. Warping can be avoided by building in a heated chamber, by using PEI (PEI bed surface - Hardware - LulzBot 13) or Buildtak bed liner. Kapton, glue, acetone slurry,hairspray (aqua net), blue tape, white glue mix will all work. The white glue mix can be made so strong that the parts will break the glass coming off so be careful. By using Buildtak we have found the parts become stronger by curing under stress.

Warping can be caused by long unbroken, straight lines of filament being put down in the slic3r engine and breaking up the pattern helps. Build plate heat traces cause some issues too as others have noticed that moving the part around on the plate can help. Avoid drafts and fans with ABS. Use an enclosure.

Currently I am testing and using Buildtak in a production environment. Its been the best stuff that I have used so far.

Two points:

1. The spring loaded mod is a must, but I had to go another step further for exotic filaments. This knob adjust makes it easy to apply just the right amount of force on the filament. Thingiverse - Digital Designs for Physical Objects 18

2. I’ve found that the NEW large rolls of PLA from MakerBot reguire ABS temps to avoid jamming. That and reduced print speed.

Acrylic warps over time with heat and is impossible to keep flat. I’ve gone another way with build platform issues… 2 items solved this for me. Buildtak http://www.buildtak.com/ 8 for the surface… I’ve not had to replace it after hundreds of hours of jobs… and an alum platform (because i upgraded to a heated platform ). Glass could do the same. I also enclosed the chamber and put an enviromental control on it for better temperature control.

Even with Buildtak you still need a heated bed right? I’ve got access to an Ultimaker 2 and a Makerbot Replicator 2. The U2 is supposed to be ABS capable, but so far it was not delivered. Buildtak would solve the adhesion and warping issues on it right? As for the Rep2, I’d love to find a cheap way to make it ABS capable.

Could you expand a bit more on what you did for the larger rolls? My school just bought a few of them, and I was the first one to test them out. My jobs, ranging from 3-5 hours, will start out great, and have even worked for hours, but always get some kind of jam before completion. It’s not the printer, as its in good condition, and has printed jobs well with other, smaller spools. However, its a 4th gen Rep2, and the set temp for PLA is already 230 C, so should I try to push up to 240 C for the larger spool? I’m already printing at sluggish speeds of 40 or 30 mm/s trying to keep the jobs good quality at low resolution.

To be honest, I barely get good results with anything I try and I’ve since been avoiding them unless the color is just too perfect to not use. My suggestion is to try and obtain some non MB PLA and see if it helps.

ok, well it’s my schools printers and materials, and I’m too broke to get my own right now, so I guess ill just have to make do. I think I’ll raise the temp, as the issue isnt on the spool, or on the print, so hopefully a bit of an increase in temp will make enough of a difference. Will the PLA be ok at 240 C? How high do you think I could go? Thanks, -L

I would suggest a few small test prints and trying hotter temps a couple degrees at a time.

A heated bed and climate controlled chamber are good for ABS. PLA is much more human friendly so I use PLA when I can. May I suggest to make a portable, contained heated bed using a piece of glass from an old scanner tray or a FLAT piece of 1/8" spring steel (stays straight, but flexes) and Buildtak . Go to Ultibots and buy some supplies like the heater trace stickers from 3M then get a controller… etc…

Make sure those big rolls are spinning freely in the holder and try adding a filament cleaner (cloth). It is possible that the filament has dust on it. Dust can accumulate and end up jamming the nozzle. I print at 215C for MB PLA with good results but I switched to 9 euro / kg rolls at microcenter in the USA. The plastic comes from Toner Plastics in Pennsylvania. Makerbot, Lulzbot, Stratasys all use the exact same supplier and formulation for the ABS so maybe its the same for PLA.

Cheers