Want to know more about the Zortrax

Do a member of Facebook group “Zortrax 3D printer users”

That includes individuals who work at Zortrax

tridos

6

What do you mean by medium quality and poor colors? So far I’ve had absolutely no problems with any of the filaments and the quality is always top-notch. Zortrax just came out with like 15 colors for ULTRAT too.

We have v3 and v4 they are pretty much the same. But with v3 it is easier to load the filament because they have changed the filament feeding cover in v4, it is longer and that causes the filament to stuck in the feeder more than v3.

Diameter and roundness is perfect.

What about colors, it’s personal taste, but when I print in red ULTRAT and end up with orange I call it poor color. Also white ABS is not as opaque as competitors (it’s semi translucent and looks cheep to be more precise). I didn’t take greens at all because both of them (green and android green) looks like cheep fluorescent plastic. I’m happy with gray HIPS and blue ULTRAT.

What I mean they cost way too much for that.

The Zortrax is easier to use and produces better print quality. The Ultimaker2 allows more material options with less expensive filaments. We have both at work and the two Zortrax machines get used 90% of the time because the prints are so good and reliable. We use the Ultimaker2 when we want to print a large part using PLA.

Hello Tareq,

the last hardware version is V4, so don’t buy new M200 if it’s an older version. Or buy it as an used machines. Ciao Alberto

Pricing is comparable to just about all other high quality ABS and when you break it down to price per gram its an extra penny or two. That factored in with the overall increased reliability makes it cost the same or less if your looking at it from a business perspective. And they have been frequently going on sale or having good bundle discounts that make it even better.

As for color I haven’t used the UltraT red so I cant comment but I have used the red ABS and its a great shade of red. For white, I agree it is a bit translucent but I disagree on the cheep look. I think it looks higher quality than some of the very solid looking colors I’ve seen from other filaments. Some colors from other places are just too heavy and look cheesy. I think the greens are great. Customers love the fluorescent color of the android green and regular green is what I would expect from green. Android Green truly stands out and I hope the new neon UltraT colors are just as impressive. And to add to that the new line up of UltraT is going to truly make it stand out from the rest of the market.

From a reseller the only thing you will get right now is a v4.

In our office we have 4 M200’s, 2 Cube Pros, 2 Cube 3s, Taz 4 with 5 parts, Makerbot replicator 2x, Objet 30 Prime, EnvisionTEC 3SP and an EnvisionTEC Micro EDU.

As for FDM Printing, My zortrax machines have become my go to machines. I have 1/10 the failures of the other machines. The fine detail results are so much better then the other FDM printers. zortrax’s support structures are the best I have seen so far and are very easily removable. When I make the move to have a 3D printer at home the M200 will be the one I put there.

I don’t just say this because we are a reseller of Zortrax Printers, we are also resellers for 3D Systems Cube, ekocycle and cube pro printers, Axiom (Air Wolfe), EnvisionTEC and we are looking at bringing UP Box and Fusion 3 printers online as a reseller for them. We also run a print service with our printers and when I say the M200s have become my goto printers I say it because they have.

Thanks,

Tom

1 Like

ToeJam

13

I have a Zortrax and Love it (purchased new feb 2014). Never used the ultimaker2 but from what I’ve seen on-line a lot of clean up. That’s why I went with Zortrax. There are a lot of people on Zortrax forum that would know what the difference between the version are.

Nothing big is changed version to version, parts which have reports with failure rate bigger than 5% are updated and most of changes is to make our life more easy at assembly and testing time.

I love the M200 and wouldn’t use another printer.

Tareq, we are using M200 Zortrax 24/7 literally as we are running our productions on them. V4 is the latest Zsuite Application (not hardware as someone wrote). It is application translating .stl file into specific Zortrax Z-Code (think as the Gcode) to slice and place model on the bed. V4 is the latest version and have some very good features like PAUSE (you can pause print at the specific layer to change filament color (we tried it, works great), calculating print cost of the model (available since previous release), new materials (PCABS) and few improvements to speed up print generation. If you are buying printer and there is no v4 with it, no worries, using printer serial # you can logon at ZORTRAX web site and download for free latest version. Remember to download and update microcode too.

Happy printing.

Can I ask where are you located?

Best

Kuba

kuba@paliproto.com

I have every colour of filament for Zortrax z-abs, z-ultrat, z-hips, z-glass, z-petg and they all work great, almost as good as my sla machines.

I have many materials for Ultimaker and again work great.

If you only want to build abs parts Zortrax is the best.

with over 11 years operating large SLA, FDM, and Connex 3d printers i would say both Zortrax and Ultimaker are very good value for money.

Paul

www.pbmodelmaking.co.uk

www.LaserLayers.co.uk

There are different versions of the printer, though subtle it may be. Thats why you have to pick the version you have when you use Zsuite.

From a Zortrax user:

“The V1 and V3 have ball screw on the Z, the V2 have lead screw on the Z. I have both versions, and at the beginning was a problem with dimensional tolerance with lead screw, they solved it in the software so that’s why you need to choose HW version in the ZSuite.”

For the record, there are no HotEnd v3 and v4. There are v1 for regular Z-ABS, Z-HIPS and Z-Ultrat. HotEnd v2 for Z-Glass, Z-PETG and Z-PCABS, plus everything what v1 is capable. In addition ZSuite is not defining HotEnd, but it is allowing to chose material during build.To be clear v1 is still good with v4 ZSuite as long as you chose proper filament.

Best

Tareq:

Good day to you. I am a Zortrax owner/user. In fact I have (2) two M200’s. V1 - V4 are version numbers of the machine . My machines are both V4 units. As far as a recommendation goes “I love my machines”. I would waist my time on any other machine. But, that is me. You may have different needs, wants and desires. Please advise if I can be of more help. I am also a 3D Hubs member. I hope you have a great day and make the right decision in your purchase.

Hi Tareq!

It is different hardware versions. You check it in the meny on the display of the printer and choose the right version in

Z-suite.

Not a big deal, i belive.

I use my Zortrax M200 every day nearly and it is working great.

The prints are top of the line!

Best regards

Svante Sandberg

3d4you

21

Hi,

as already mentioned, zortrax is a very reliable plug n play machine. Very good quality. But only zortrax materials should be used. 3rd party abs may work. Nothing to set. Not even print temperature. Good choice if you want print results.

Ultimaker is open source and much more flexible. Can print various materials. Many settings. Some can be changed even while print is running. Good choice if you like to play with it. Quality can even be a little bit better than zortrax, but printing slower.

On www.3d4you.net both machines can be tested.

Hi Tareq!

As these helpful members mentioned, there are software updates and a couple hardware changes (v1-v2 hot end) however, what has not been mentioned is that there were multiple hardware changes to

1. the extruder cable

and one change to

2. the perforated build plate (thicker)

So in reality it is not just a software change, some of the hardware does change from v1-v4.

I have absolutely LOVED using the Zortrax m200! So much that we started reselling them!

If you have any more questions regarding v1, v2, v3, or v4 of the printer, please email me at:

service@protoripe3d.com

We would love to help you gain information so that you can make a great purchase!

Cameron

p.s. check out the pictures to see the differences…

With an after market Z-Temp addition to the Zortrax M200, it can print any material that is on the market.

I have found in my business that I have had some with Ultimakers that needed a quality print, hired my M200 to print it for them. I am sure the ultimaker can do quality but with so many tweaks needed to the settings to get that quality print, I wouldn’t even attempt to delve into that world. lol

http://www.3dzprinting.com

Hi Tareq,

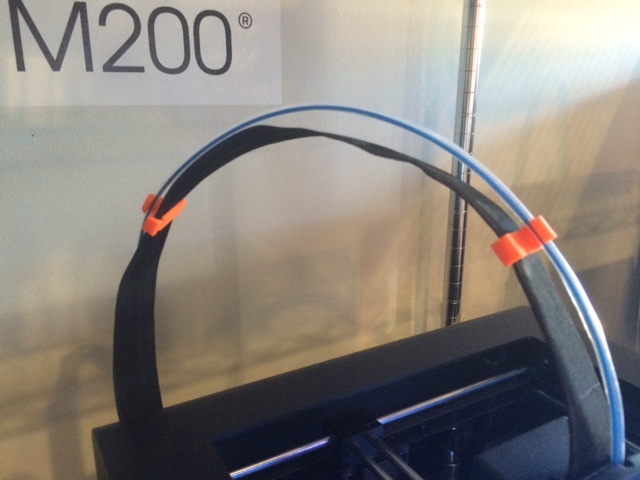

Zortrax is a great printer and if you need to have reliable printer, with filament formulated for the specific printer for the best quality prints and don’t want to spend time on thinking about parameters and settings - buy M200. After reading all entry, clarification is needed as folks mixing software, microcode and plain hardware. 1). Z-Suite is exactly 1.4.1.(commonly called v4), printer had 2 versions, first at original Kiskstarter with rounded extruder cable, quickly replaced with flat cable (by the way you should print kit keeping extruder flat cable and plastic extruder feeder together to prevent cable being damaged - see attached picture). 2). Both HotEnds v1 and v2 are supported by Z-Suite 1.4.1, both plates v1 (thinner) and v2 (thicker) are supported by Z-Suite 1.4.1 3). M200 hardware and functionality changes are driven by new microcode, again nothing to do with Z-Suite as software is compatible with new and “old” hardware, microcode is really much more important to be current…

New plate is better in preventing warping (model and plate itself, made from aluminium) and is more evenly heated. New Z-Suite version is solving bugs, changing some functions available during slicing, adding more precise slicing algorithm etc.

New microcode is adding new function like filament load and unload, time of print, progress and so on visible on LCD screen. yes, you should have latest versions of ZSuite and Microcode, but if you can buy older without at bargain price, go for it as every thing you can download from Zortrax web site. Confusion is created by some of the distributors, resellers as they proclaimed different version of Printer by bundling HotEnd v2, Plate v2 and sometimes side covers together and selling it as v4 or “Professional”. All parts can be acquired separately and assembled into your printer, again nothing to do with Z-Suite.

Base printer in US is around $1,990.00, other elements varies. New printer generally are shipped by Zortrax with HotEnd v2 and plate v2 and side covers can be purchased separately, as they help preventing model warping.

if you have more questions please let me know

Kuba@paliproto.com