Hey guys,

It seems to be a pretty straightforward one , but I can’t pinpoint what I should do exactly. The main question is - what should I play around with to determine the perfect settings for the printer to place the filament in the accurate location. E.g. The Nasa wrench requires quite a precise point for the whole thing not to be printed stuck together, but I can’t achieve that although the prints turn out really nicely (visually).

Note: I am using Esun filament 2PLA , which is half the price of Colorfabb so maybe the quality of it might be the issue here.

I’ve came across a problem which I am not sure how to solve. I’ve assembled the Turnigy Fabricator myself 6 and printed the first Marvins 4 and they look great. In fact, most of the prints turn out really well without much of a hassle, the problem comes when I start printing things with moving elements in them.

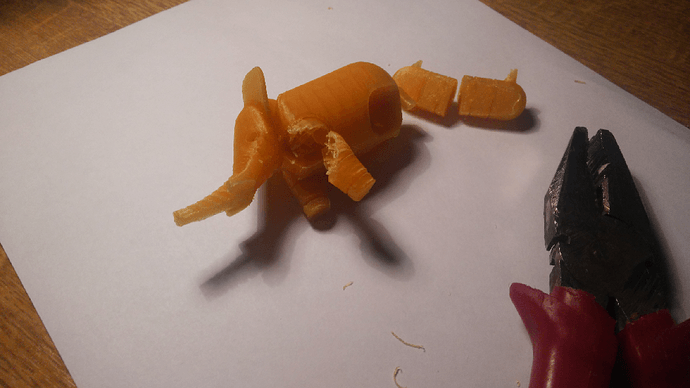

For example this bearing printed fully stuck to everything without anything moving (granted I scaled this one down to 50% of its original size)

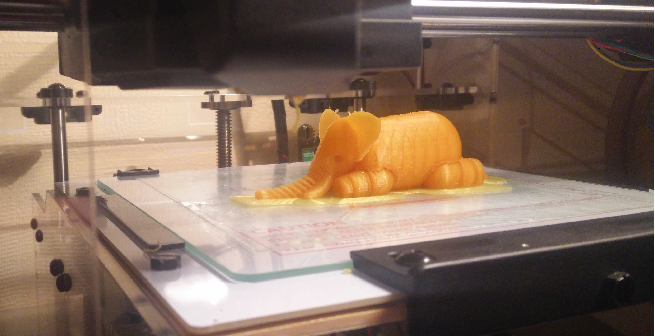

Same happened with this beautiful elephant (turned out pretty well , but the legs were stuck)

Well, not exactly stuck. I managed to move them, but I am not sure if this is how it is supposed to work (??)

One thing I did was realize that my Cura was interpreting the filament diameter wrongly and fixing that helped a little bit. Along with reduced temperature I managed to print the big ball-bearing which actually moved, but it wasn’t perfect still.

The big bearing and the elephant are actually moving now, but still not as smooth as I’ve seen other prints do. (I know that this visual with the kick-ass soviet union art in the background really helps me tell the story)

So here it is! I want to start printing some e-nable hands or something else functional and want to make sure that I can solve this first.

Thanks for the help!

created

Oct '15last reply

Oct '15- 4

replies

- 13.7k

views

- 3

users

- 10

likes

- 3

links