Hi all!

So I’m having some issues with my printer that I hope you can help me with. I’m currently trying to print two copies of a cookie cutter at the same time, and I’m having top layer issues on only one of them! I assume that this is a software issue, since one of the prints always comes out ok.

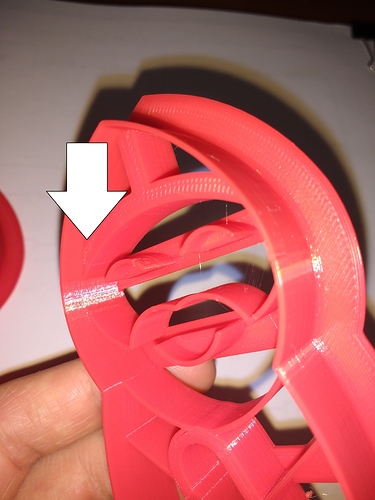

If you look at the picture with the white arrow, you can see the gaps in the top layer of the infill. It’s difficult to get a good picture of the issue - but trust me, the surface quality is noticeably different between the two copies of the cookie cutter. There are visible holes in the top layer of the print.

I’ve tried rotating the models on my print bed, but that doesn’t seem to make a difference - there’s always one of the models that has this issue?

Any ideas?

Thanks!

Relevant info:

Printrbot simple metal

Sliced with Simplify3D

100% extrusion, 90 mm/s travel, 2 mm retraction, 60 mm/s retraction speed

First 3 layers at 200 C, rest of the print at 190 C

3 top layers, 3 bottom layers, 3 outline shells

20% infill

Coasting distance 0.25mm

created

Nov '16last reply

Nov '16- 2

replies

- 1.3k

views

- 1

user