Hi,

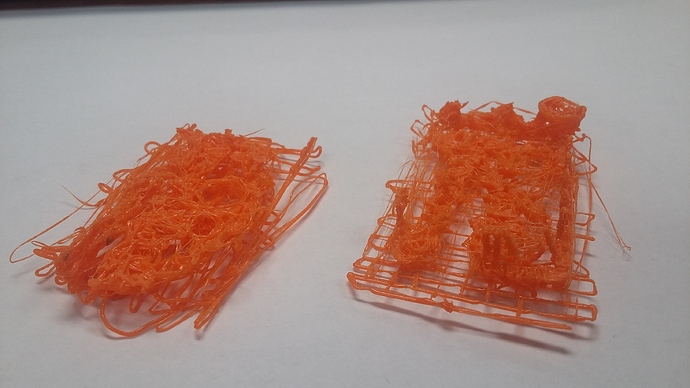

I am a teacher at a small Charter School and found a CTC 3D printer in a back room. Apparently when it was purchased a few years back no one could get it working. I took it home and after some testing with a lack of Z-Axis movement found the Z-Axis cable was plugged in tot he wrong place on the motherboard. The first image is what I was getting prior to fixing the cable. I used MakerBot to connect with the printer.

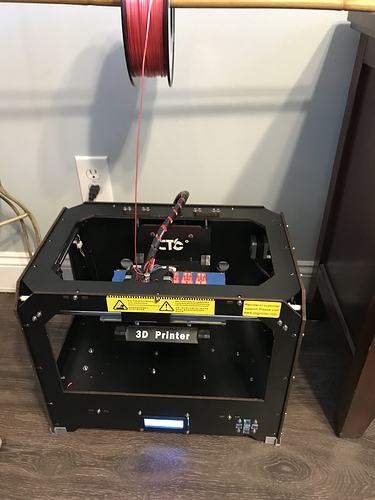

Unfortunately I also upgraded the firmware to Sailfish when I fixed the motherboard and the second…this is the result.

I’m getting Z-axis movement but the print quality is crap (I have tried using both MakerBot and ReplicatorG with no improvement). I have tried the atomic cleaning method and the PLA came out clean (although a flat nose instead of pointed). I have tried adjusting print speed (as best I can using either system) and temperatures. I am at a complete loss. As near as I can tell I am dealing with something along the lines of under extrusion combined with not sticking to the plate (the picture represents the best I’ve managed to get since the filament usually curls so much at some pint that it balls up the whole model).

I can provide more images and information if you tell me what you need. I would really appreciate any help. If I could somehow get back to the original firmware that might help (minus the lack of Z-movement the original prints were significantly better), but CTC’s website has proven less than helpful in that regard.

I had the same problem with under extrusion and not sticking. There is one known problem with these printers when you use sailfish as I eventually figured out and it’s that the temperature sensors can read the temperature incorrectly there for the nozzle element and the bed element do not get hot enough. I know this sounds crazy but try setting you nozzle temperature to 260 and your bed temp to 110. I also use a glue stick before the print on the bed to help with adhesion.

There are some other tips and tricks to help with printing on this printer, you may contact me directly through email / FB if you like to help you further.

I hope this helps.

Best

Nathan

Nathan,

Thank you for the advice. I turned up extrusion temperature to 260C and saw an initial improvement. Here is a picture (someone tore it up not realizing we needed the failed sample to help fix it):

I took the image upside down to better show how the filament started. Unfortunately it quickly went back to how it was and then down hill from there. I have not been able to recreate the initial improvement in the above image.

You can contact me directly at my work email: jmcknight@technicalacademies.org

Hi is this the CTC with black wooden frame and dual nozzles?

Yes, the black wooden frame and dual nozzles. Here is what I got on my initial layer today:

I confirmed my suspicion that the clicking (sounds like gears struggling) coming from the extruder coincides with inconsistent thickness in the filament being extruded. If left to continue the model continues being built similarly to the model in the first picture (on the right side). The base is no where as dense as the test image suggests it should be. Also the nozzle occasionally bumps into the extruded layers while building.

Ok i have the same printer and would like for you to put on some new 3m blue tape if you have any and level the print bed. I am going to send you a file to print it will be and X3G file so just load it directly onto the SD and print. no need to slice i’m going to slice it in S3D with my settings. Are you using PLA or ABS?

I am using PLA but do not have the SD card. Could a SD card from a video camera replace it?

Yes as long as it is the correct size

The one i have is an SDHC 4GB

When i said size i meant physical appearance of the card not the GB of memory. I think if your running sailfish it can handle up to 16GB card not sure though. I have always used the 4GB card that came with the printer

also save any photo’s on the card to pc and reformat the card to FAT32.

almost forgot. When you level the bed be sure to preheat the bed to 50C then to the leveling procedure.

Reformatting now, you have the file for me?

Verry important to make sure you preheat the bed to 50c then level it. B4 printing that file

Let me know how it turns out

No luck. Too cold and the PLA was curling on exit.

Saw how help full you were. Mine prints well but I can’t get the second head to print. Can you help? Hopeful you have a dual head.

Hey Donblevins

Did you select which head to print with in makerbot desktop? When you put your print file through makerbot desktop software you need to click on the model then click the Object information icon on the left (Its a picture of the letter i). Once you have done that you can then selsct which extruder you want to use.

Hope this helps

Best

N

Hey Donblevins

Did you select which head to print with in makerbot desktop? When you put your print file through makerbot desktop software you need to click on the model then click the Object information icon on the left (Its a picture of the letter i). Once you have done that you can then selsct which extruder you want to use.

Hope this helps

Best

N

I have the ctc replicator. Knock off. So I’m using a different splicer. I haven’t tried the makerbot GUI. Does it work with the CTC replicator.