“Flat” and “rigid” are terms typically used to describe electronic devices. But the increasing demand for flexible, wearable electronics, sensors, antennas and biomedical devices has led a team at Harvard’s Wyss Institute to innovate an eye-popping new way of printing complex metallic architectures – as though they are seemingly suspended in midair.

This laser-assisted direct ink writing method allows microscopic metallic, free-standing 3D structures to be printed in one step without auxiliary support material.

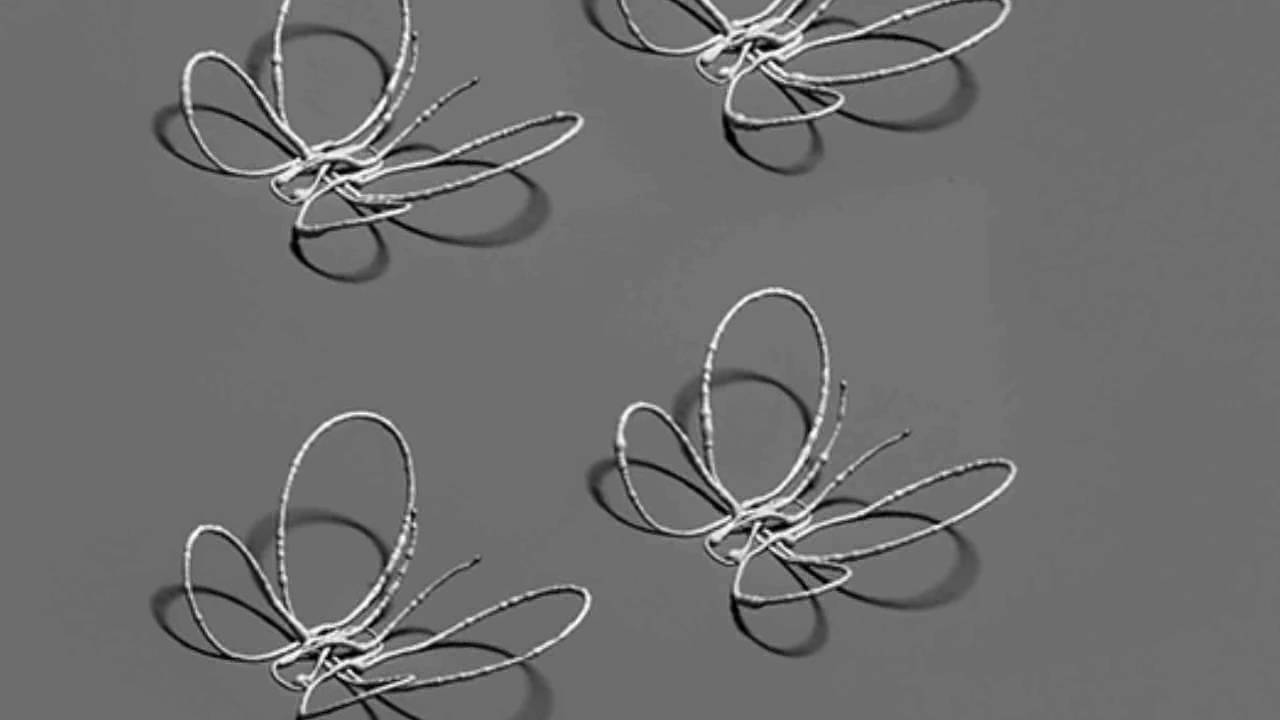

The Research team used an ink composed of silver nanoparticles, sending it through a printing nozzle and then annealing it using a precisely programmed laser that applies just the right amount of energy to drive the ink’s solidification. The printing nozzle moves along x, y, and z axes and is combined with a rotary print stage to enable freeform curvature. In this way, tiny hemispherical shapes, spiral motifs, even a butterfly made of silver wires less than the width of a hair can be printed in free space within seconds. The printed wires exhibit excellent electrical conductivity, almost matching that of bulk silver.

created

May '16last reply

May '16- 1

reply

- 953

views

- 2

users