Hello all,

I got a Lulzbot Taz 6 last week and simplified 3d and am trying to learn the ins and outs. Big stuffs not bad so far but small is hard. Here is a picture of baby groot and a gun the hands and the guns trigger area simply wont print correctly. I have it at .15 resolution, 100% infill (tried 15%) , 3000 mm/min speed and 210c temp. Any assistance would be appreciated to figure out how to get the smaller stuff working.

Hello puck34696!

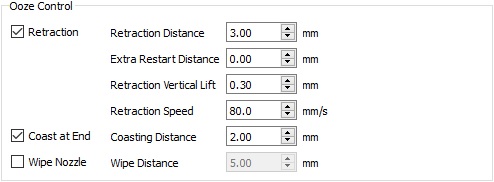

Oh, we’re going to get this working. FIRST, Simplify3d is awesome and you’re awesome for getting it. SECOND, and I say this only because I would hate to see other people yelling at you, but people might tell you to switch your display speeds to mm/sec instead of mm/min. Maybe not, depending on where you live, but if you want to, Tools > Options > Preferences Tab > Speed Display Units. THIRD, and this is just from my own personal experience, but 3000 mm/min (50 mm/sec) might be too fast for the smaller parts you are trying to print. I was printing a dozen small 28mm tall figurines for a buddy of mine, and was trying to print at 50-60 mm/sec, only to find that the figurines weren’t very smooth looking. Maybe try slowing down to 20 mm/sec or less? That may also help with the stringing between the arms and legs. May I ask what your retraction settings are? I spent a fair bit of time perfecting those for my Makergear M2 because I was seeing stringing, over-extrusion, and globs. I finally landed on the settings I’ve attached in the picture, and that also solved a lot of my problems with printing small figurines. Now, your printer will probably require some different settings, but hopefully that would be a good starting point. Let us all know if this helps in any way. And please feel free to ask as many questions as you want!

Zapaer

3

Hey @puck34696

Just adding on to what @SolarCell007 wrote, it may help printing multiple copies at the same time especially for smaller objects. This is to balance out and reduce the heat accumulation in one area. You see when the nozzle sticks around one area for too long, the plastic tends to absorb that heat and result in a poor finish as it’s not able to cool down to below the glass transition temperature fast enough.

Also speed wise, with a Taz 6 you should be easily able to print it at 50mm/s. A good rule is to keep your flow rate below 8mm^3/sec.

This is determined by: nozzle diameter*layer height*print speed. It should never be more than 8 for good quality prints.

Also for smaller prints (delicate) use a smaller nozzle size (0.4/0.2mm).

Finally, make sure you have a good part cooling fan. And if all that doesn’t work, try lowering the hotend temp by 5-10C.

Happy printing!

P.s. S3D has a great website to help you solve your print problems you should check it out: Print Quality Guide | Simplify3D Software

WOW first off the support on this forum is great! I love the details and @SolarCell007 thx for the unit tip saves me from converting every time!  My settings are below, I love all the options in S3D and am really trying to learn them though I know Cura can pump out some good quality but isnt very optimized and is wasteful (support structure size etc). Should 2mm layer height be good for smaller figures ? I’ve tried 1.5 and 1 but they either clog or dont stick at some point and the printer goes on printing into thin air. Thx both of you let me give theve a try and see what I get.

My settings are below, I love all the options in S3D and am really trying to learn them though I know Cura can pump out some good quality but isnt very optimized and is wasteful (support structure size etc). Should 2mm layer height be good for smaller figures ? I’ve tried 1.5 and 1 but they either clog or dont stick at some point and the printer goes on printing into thin air. Thx both of you let me give theve a try and see what I get.

https://goo.gl/photos/3FX856gUpiWVyzw89

ok so what am i doing around, trying with the setting above I get jamming and fil. grinding, using the default S3D settings I get what you see below.

please look at these and offer suggestions if you can.

temp 205 head

temp 60 bed

1.75mm fil.

.2mm layer height

retract speed 1.5mm

retract dist 30

infill 15%

other default settings