Bavilo

1

Hi everyone,

I am having some troubles with my Original Prusa i3 MK2 and getting the Marvin print to turn out good. The Printer was a kit but calibration says that everything is perpendicular. Belts and everything are also tensioned, I don’t believe that something is stuttering.

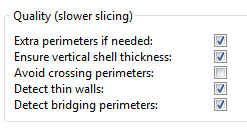

I am using the Prusa Slic3r version 1.34.1 with default profile settings except the changes on the attached settings screenshot. Furthermore I am using Colorfabb Economy PLA (2.2kg) in white with these temperature settings - 210°C / 55°C

I have completed the print in 100 and 200 microns. 100 micron looks very rough with some layer jumping near the top. 200 looks somewhat better but still very rough.

100 microns

200 microns

Any thoughts?

I really want to get this sorted out and start printing in good quality so I can open my hub.

Bavilo

2

Here are the settings I changed.

I would drop the temp 5 degrees at a time and see. Heat is a problem printing Marvin.

You could reduce speed some but the default for PLA isn’t to bad. I think I was at around 20mm/sec but on a different printer.

You can also print 2-4 at a time which will help on heat.

Your .2 one isn’t bad. It may just be the filament also.

You could try backing off the extrusion multiplier just a little like no more than .05.

First thing maybe is do one of the test prints on the SD card and see how that goes and compare how the filament looks.

Bavilo

4

Good idea, I believe Marvin is included on the SD Card, I will print this with the silver Prusa filament, followed by the Colorfabb. I will post results once the prints are done!

Bavilo

5

Ok so I tried printing Marvin that came on the SD Card. It still not as good as it should be…

Printed with 100 microns

Hi Bavilo, I also had those issues and what I ended up doing was buying the silicone socks from e3d and did the PID tuning with the sock on. After that it came out perfect  It has to do with the temperature deviation being to big… Here is a link to a video explaining how you can do it: E3D Silicone Sock on Original Prusa i3 MK2 + PID Tuning - YouTube

It has to do with the temperature deviation being to big… Here is a link to a video explaining how you can do it: E3D Silicone Sock on Original Prusa i3 MK2 + PID Tuning - YouTube

Fuli

7

Try is with the silver prusa filament and like wirlybird said, play with the temperature. Printing speed for a marlin should be around 20-30 mm/s

Do you print at normal speed? Try use another slice. In use cura with my prusa mk2

In my case i have live-adjusted the Z-axis (you can set this in the settings menu) to -0.300. That was a result of the test prints of calibrating the first Layer. It is well documented in the manual: http://www.prusa3d.com/downloads/manual/prusa3d\_manual\_mk2\_en.pdf

Chapter: 6.3.9.

After fine-tuning this “live z-axis” i got much better prints and the first layer is perfect.

Probably this helps for you, too?

Greetings,

;-liver

Hello, what speed did you use ? Have you try with Cura ? I have the same printer as you, in kit, and i had some issue with slicer, this is why i use Cura and the result are compliant with my expectations now. Z adjust is also -0.300 to get a good first layer. Let us know ! For economy silver PLA from Colorfabb (2.2kg) i put 213° for hot end and 60° for bed. ED

The live z adjust is dependant on each individual persons printer and the height of their PINDA probe, which is manually adjusted

Exactly!

I don’t know how many I have seen with damaged beds because someone said “set you live Z at xxx” or “you live Z needs to be at” and then they crash the nozzle into the bed.

Bavilo

13

Correct,

My PLA live z-adjust is at -0.615 mm. Which makes the first layer look perfectly fine.

I have done another print yesterday, I will upload the result in a few hours. I have reset all my changes in the printer profile and used the default setup. On top of that I have tensioned the belts a little more (Not sure if this had any effect). But the print came out much much better.

Pictures will follow soon as I probably need to tweak it some more!

He looks pretty good.

I would work on a .2 version and get that nailed first before fighting with .1!

Remember temps are going to be one of the big issues on Marvin so printing 2-4 at a time can help. Temp on yours doesn’t seem bad though. Speed may be a factor. I printed at about 20mm/sec but then heat can become a factor more.

I think the settings are close so small changes and one at a time to see the effects of the change.

Some of the problem areas are good on yours like the key chain ring.

Bavilo

16

Thanks for this video!

I was having these oscilations as well and I thought it was normal. Now after the calibration the temperature is SPOT on!

Bavilo

17

Ok so here are my latest prints:

200 microns looks good. 100 is still screaming for improvement. Is it still printing too hot? This was 205°C

I haven’t used slic3r much, but is there a minimum layer time? It looks kind of like the layers aren’t having much time to cool. Try printing one with a cooling tower next to it (print a Marvin and a simple small cylinder at the same height as the Marvin) at the same time and see if that helps. It also looks like you may have some z wobble. Make sure you y and x belts aren’t too tight, as that can cause the same issues. Print a 20mm calibration cube with low infill and extended in the z axis to 100 or 200 as well. This should give you an idea if you have z wobble around a certain height. Once it’s done if there is ringing around 110mm you know that something goes wrong at that height. I had an issue where my smooth rod for the right side of z was a little bowed, and at 140mm it bowed inwards, causing the x axis belt tension to get thrown off, causing some issues. Let me know if any of this helps.

What speed are you printing at? Maybe try slowing down a bit?