Lol mallet or hammer?

Depends on the print. Really it’s just Newtonian physics. Taking a print off the bed is like pulling a table cloth out from under a fully set table. With the right amount of force you can make that print move away from the bed without the bed absorbing much force. When the force is properly placed between the part and the bed you don’t damage either.

If you have a removable bed pla prints pop themselves off after 2 minutes in the freezer, I use a use a very particular hairspray for bed adhesion with PLA.

As for abs, kapton tape is the way to go, a careful knock with a rubber hammer or if you can ease a chisel infer a corner that works wonders too.

Some good ideas on here I will have to try feeler gauges and dental floss

Just use this, I was skeptic at first but it turns out to be an excellent tool because the edges have a varying thickness:

http://shop.turtlecreations.nl/3DPrinters/3DPrinterAccesoires/buildtak\_spatula

Oooooh.

When I chipped my 2.0 I just bought Buildtak and have not had a problem. Its just a bandaid lol

Oh no! If the build plate is just glass, I cut my own pretty easily from glass at Home Depot / Lowes and a glass cutter (also found at the same place). Just use the cutter to score along the line to cut, put the scored line at the edge of a table and then a quick, even snap will get a clean break.

Another option is to go to a local glass shop. They will cut a pane for you and it won’t cost too much. I couldn’t manage to cut a 18"x18" sheet for my larger printer on my own without cracking it and went to a glass shop.

Either of those options should get you a new glass print bed (assuming you’re on glass) without having to wait for shipping.

This is a great idea ^^ The only issue is you would have to buy the pcb to heat the bed. Probably all together cheaper than XYZ if unless you have a valid warranty. EBay would be another good place to check, I have seen them listed $10-15 cheaper than buying from XYZ.

Also a good idea and the Buildtak might be an upgrade. Of course you could go grab some glass to hold you over and also order some Buildtak.

i use multiple single edge razor blades, make sure the bed and part are cold, or else you will warp the edges/corners, start a razor blade in each corner and gently tap them around the print to loosen it. Usually it will just pop off, if it still doesnt, i take the handle of a screw driver and tap it (with some force) on each side till it pops off. I do this all the time, cause i would rather my completed print be difficult to remove, than it coming loose halfway through a 12 hour print and having a pile of filament laying there.

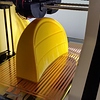

I used copper tape for stained glass to build my own heater for an oversized print bed on my Robo3D. I figured out how long the copper tape needed to be to match the resistance of the standard heater then spaced the strips so they covered the whole plate. Once installed on the glass they were soldered together and covered with capton tape to prevent damage and shorts. The bed heats quicker than the production bed. Here is a picture of the bed while printing a new customized seatback for my grandsons Big Wheel.

That’s nice, is that the original Robo R1?

I shoot a little canned air upside down on stuck prints and they pop right off.