Hey guys,

You may be familiar with a technique called hydrographics which is mostly used for autobody parts in large scale contexts.

Hydrographics machines are used to apply graphics, designs, and patterns permanently to objects. Machines typically cost between $50,000-$150,000, and use toxic chemicals.

We have invented the world’s first desktop hydrographics printer. The Finuvo Aqua allows hobbyists, 3D printers, and prototypers to apply beautiful, brilliant designs to their 3D printed parts, using a completely safe and easy method.

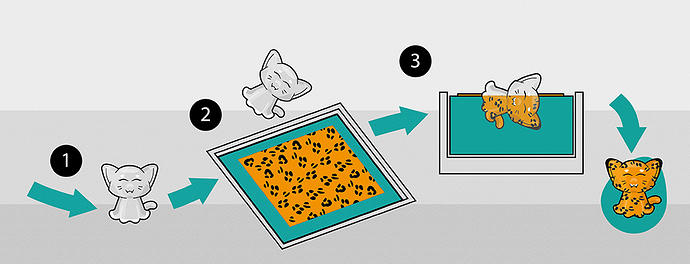

How does it work?

A special hydrographics film is layed on top of the Finuvo Aqua and the 3D printed object (or any object, really) is carefully dipped into the vessel. When it comes out of the Finuvo Aqua it has a permanent coating on it.

Computer mouse with beautiful cherry wood coating

This is what the process looks like on our prototype Finuvo Aqua:

And here’s the final product:

Marvin printed on the MakerGear M2 and dipped in a funky pattern with the Finuvo Aqua

When we say permanent, we mean perfectly solid. The coating will not fade, flake, or crack. We’ve put it on shoes, computer mice, water bottles and tons of other objects and the design is still as brilliant as ever after heavy use.

Terminator Exoskull printed on our FormLabs Form 1+ and dipped in brushed aluminum coating with Finuvo Aqua

The film comes in almost unlimited designs – wood, camo, animal prints, flames, funky patterns. Soon it will also be possible to design your own film with custom graphics.

We want to make 3D printing even more beautiful and awesome, and we want to make hydrographics accessible to all of you.

Follow us on Facebook for updates 8 (and info on our upcoming Kickstarter campaign)

Also, we’d love to get your feedback: What do you want to see dipped? Tell us in the comments!

created

Aug '15last reply

Feb '16- 54

replies

- 10.1k

views

- 23

users

- 97

likes

- 4

links

There are 54 replies with an estimated read time of 5 minutes.