HanCon

April 13, 2015, 2:48pm

11

For a recommendation pls. firstly share your settings from Cura and additional information. You can either link to the Cura .ini file here or list the settings.

Temp. material (should be around 225-240)

Temp heated bed (should be about 100 C)

Printing Speed

Fan on/off (I suggest off)

Name and manufacturer of the used ABS

Where is the part bending? Pls. share a few images of the printed part

Jory

April 13, 2015, 2:56pm

12

Try adding “mouse ears” to the edges of the print. This should help. The size of the “ears” depends on how big your part is.

My best experience with similar parts was:

set heat bed to 104 Celsius

use no glue but acetone/ABS slurry

enclose the printer that the chamber keeps the temperature

Fan off.

print slow

set the material flow to 100%

layer 0,1

Nozzle temp 240

use high quality ABS

ShaunD

April 13, 2015, 3:12pm

14

Is there any reason why you’re printing the parts standing up? The holes are likely to be problematic as they’ll be full of support material.

The first thing I’d do is to lay the parts flat so you have less height to warp and use a brim as has been suggested before

Hi Jekyll,

I have an UM2 too.

1) Try to callibrate the bed so the first layer comes out almost transparent. Set on Cura the first layer as 0.1 mm.

2) Use the stick glue on the bed

3) Set the Bed Temp to 100°C

4) Set the Noozle Temp. as descried by the filament producer.

5) Set a slow printing speed <55 mm/s

6) Cover the printer with a Plastic so you can mantain the temp. inside.

Cheers

Ah!!!. I also had that problem with big parts. Don´t get crazy. The solution: print it in PLA (It won´t bend. Don´t lose your time printing big parts in ABS).

paul9

April 13, 2015, 4:10pm

17

Hello

I think you can solve the problem simply by using this special ABS made by this company. This is a new solution fits precisely to avoid this kind of problems.

http://www.filoalfa3d.com/it/abs-175/95-abspecial-o175mm-azzurro.html

Capton tape, totally cleaned from grease. 115 deg on the bed and cover the top of the printer where possible with a sheet of paper. just use normal ABS. It is the heat (cold) there is your problem. I have printed very large ABS print this way on my UM2. Good luck.

rspehr

April 13, 2015, 11:37pm

19

Have you tried mixing Acetone (Nail Polish Remover) with scraps of ABS to make a glue slush. You must do it in a well ventilated area. You then use a business card to slush it onto the glass. This makes a base that will not let your part come off. I use it with every ABS print. It works better than any other thing I have tried. Enjoy…and be careful to mix in a well ventilated area. I can send you a bottle of the mix if you want. Postage and the mix for about $10.00. Let me know how it goes. rspehr@gmail.com

Hey @Suminvent , what is this about? Did your comment got deleted or…? Thanks

@gabriela3d : no, i did not saw the comments beneath and just asked the same questions

FINS3D

April 14, 2015, 10:01am

22

Apply a thin layer of ABS Glue (ABS + Acetone) on the glass, it works like miracles.

Fans Off and closing up the openings help too…

MG3D

April 14, 2015, 7:42pm

23

This position looks to be the best. Try to print it very slowly without forgeting the hard glue spray!

Jekyll

April 15, 2015, 1:48pm

24

Hi everybody,

Thanks for your very interesting responses!

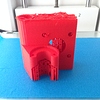

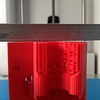

I’m using an Ultimaker 2, so 3 sides are closed. Open on the top and on one side. I tried with heated bed up to 110°C. The part is still curving on the bottom and the wall aren’t straight, specially on the bottom. That means it’s too hot on the bottom right? Do you think another position will give better results (higher contact surface with the heated bed)?

Two pictures are attached.

Sorry, not sure I can share the part because I’m printing it for a customer.

You should use brim and rafts. The 110 deg on the bed is just perfect. Use rafts to lift the model from the heat to avoid the “elephant foot”.

1 Like

HanCon

April 15, 2015, 3:35pm

26

Why do you use blue tape on the glass bed? This is not required if you have a heated bed. Have your tried without?

I am very curious to see if you find a solution that works! Let us know if you find one!

Hi Jekyll,

see my response from 2 days ago.

for the housing you can use some plastic foil.

I have had the same problem like you are facing right now.

following the steps I told already I had only very satisfied customers.

happy printing.

Alfred

I insist: have you tried to print this part in PLA…? Why not…?

Jekyll

April 16, 2015, 9:47am

30

Hi, easy answer… the customer asks for ABS.