Hi all,

My Rep 2X will print the raft (HIP) and about 3 layers of the part before air printing. Post investigation it seems like heat creap is softening the material until it flattens and either doesnt grip the stepper or goes down into the nozzle and jams because it’s too wide. Raft always completes printing but then is also always jammed by the time the 3 layers of regular plastic is printed and starts air printing so I assume the HIP has then succumed to the heat creap.

Temp measurements are (using IR probe):

- steppers are around 66degC after 30mins or printing (Hot! Can touch for about 4 seconds). All gantry and extruder steppers are about the same temp.

- extruder spring assembly about 56degC (these are now aluminum upgrades)

- mounting bar/block about 70degC

- aluminum carriage (upgrade) was about 100-110degC

My first thought was that the stepper motors are contributing to the heat creep but google searches suggest 60-70degC steppers are normal. I added heat sinks to the steppers - no diff. So the nozzle heat is then creeping up the thermal barrier tube? How is this happening when it didnt before? I had original thermal barrier tubes in there when this started, but figured maybe they lost lubrication so I bought new ones…no diff. I replaced the fans (same model). I am used to replacing a lot of fans too and never had a problem before…these fans fail bearings often! Fans are currently running fast and furious (as they should). I have heat sinks and fans in proper orientation. (fan labels not visible, fan to fins.) Could the aluminum carriage be causing heat creep? I can’t see why since the the nozzles and steppers would conduct to the mounting bar regardless, so if anything the carriage would sink heat and dissipate more than conduct it. Aluminum extruder upgrade has a tight grip on the plastic - much more than old makerbot ones. Also replaced thermocouples in attempt to fix. I’ve dissassembled and reassembled the extruder about 30 times (not exaggerating!) as much of the upgrades or replacements were done 1 at a time.

Any suggestions!?!?! I am at the end of my rope.

Upgrades:

My Rep 2X was working great for a few years with the added Bottleworks mods (glass plate + aluminum arms). A few months ago it started this air-printing. So I decided to do some major upgrades to the head unit to figuring it would fix it and improve it. Upgrades include aluminum carriage & aluminum extruders, new heater blocks, nozzles and thermal barrier tubes.

1 Like

You don’t mention the temp you are printing at. Also has the extruder been apart or adjusted at all before this all started?

Printing ABS at 230, HIPS at 250. Build plate at 110.

The printer started air printing after many good prints, wasnt after a disassembly. I have had it apart before then many times for simple maintenance. Disassembly and reassembly wasn’t anything new for me. The Rep2X as they say is an “experimental” printer, not as in “for experimenters” but as in “this printer is ‘the experiment’ and you may need to fix me often”. I’ve been very happy with it though, it’s a good printer. It’s just a Gutenburg versus a xerox. A built my own CNC mill, PCB stencil printer, reflow oven and maintain a Samsung PnP machine so not new to mechanics and maintenance by any means.

I attached a pic of the failed print now that I am an approved user.

I haven’t used HIPS so can’t advise on that!

Otherwise temps seem ok. What print speeds? I might slow way down and see how it goes.

Heat creep is usually not a real problem for ABS. More likely to be to fast a print speed for the temps.

chanman

5

I had the same problem with my Replicator 2, changed nozzles, heat tape, settings but it turned out that after disassembling the head to clear out a clog that I put the fan in backwards. You should not see the label if the fan is put on correctly.

Correct. I dont see the label.

RCole

7

What are your settings for retraction?

I had a similar problem with jams after a few layers. Turns out I had too much retraction. Pulling the hot material up too far will increase the heat creep. I changed my retraction to 0.2 mm and got a completed part (after 8 failed ones). I have settled on 0.4 mm to reduce some of the strings that I saw in the part 0.2 mm retraction. My original was 1 mm retraction and it always jammed.

Thanks Robert. I will give that a try! Here are the settings, looks like my Retraction distance is high (I never touched these settings btw):

Retraction Distance: 1.3mm

Retraction Speed: 25 mm/s

Restart Speed: 25 mm/s

Extra Restart Distance: 0.00 mm

Extra Restart Speed: 25 mm/s

While I am at it, my print speeds are (in mm/s):

Bridges: 40

First Layer: 30

First Layer Raft: 50

Floor Surface Fills: 90

Infill: 90

Insets: 90

Outlines: 40

Raft: 90

Raft Base: 10

Raft Surface Fills: 90

Sparse Roof Surface Fills: 90

All those parameters have the “Filament Cooling Fan Speed” set to 0.50. I assume this is PWM duty cycle…should this be increased to force more air over the heat sink?

cobnut

9

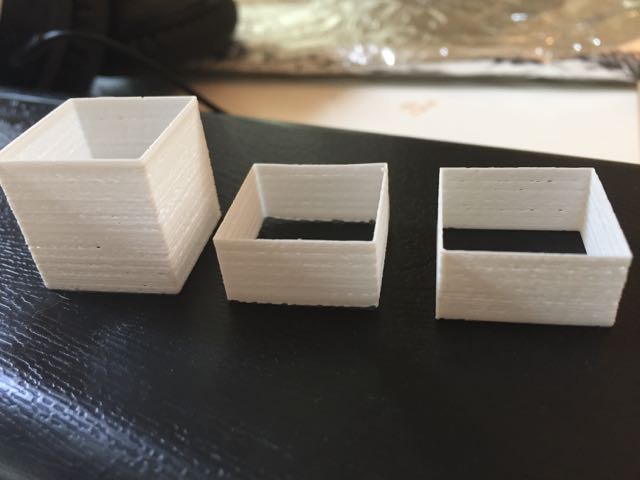

Hi @guru_florida I had this problem on my FF Pro a while back and that appeared to be over-extrusion; it seemed like too much filament was trying to be pushed through the nozzle, making it “back up” inside the extruder gearing until it jammed, quite spectacularly in some cases (see photo). I say appeared because although the problem went away when I reduced the extrusion rate, I can’t positively say that’s the reason.

However, if the filament is jamming or stripping, you should be able to see evidence of that in the filament itself, if it’s jammed, well, that should be obvious, if it’s stripping you should be able to see the “worn” area on the end when you retract the filament. If you can, when it next happens, try and disassemble the drive so you can see the filament entering the hot end, that should tell you a lot about what the problem is, or should at least rule out stripping/jamming…

Wow! That is a jam.  What I can see with mine is that the filament is flattened, that’s why I suspect heat creep primarily. I.e. the filament softens due to the heat and the new extruder upgrades applying more gripping force. It may also be partly because of over-extrusion though too. I have measured and entered my filament diameter but I did replace the nozzles and maybe the nozzles aperature is smaller (they should be 0.4 but I cant measure it). Is there are way to test if I am over-extruding? Or do I just have to do trial and error?

What I can see with mine is that the filament is flattened, that’s why I suspect heat creep primarily. I.e. the filament softens due to the heat and the new extruder upgrades applying more gripping force. It may also be partly because of over-extrusion though too. I have measured and entered my filament diameter but I did replace the nozzles and maybe the nozzles aperature is smaller (they should be 0.4 but I cant measure it). Is there are way to test if I am over-extruding? Or do I just have to do trial and error?

Thanks!

Colin

PDXDDD

11

I have printed a lot with my Rep 2X!!! it is a duel head machine but really unless your running just one side at a time it can be a total pain. I like to think of the (helps me with the $3200 expense) printer as coming with a spare set of parts since it has the duel head assembly that is flawed by design. There is no adjustment between the print heads (like on the new ultimaker 3) an offset of the hot ends. i’ve noticed when printing at higher resolution’s (under 200 Microns .20 ) the idle print head will ram the layer the other head just printed. to prevent this I just use one print head. I wanted to use both print heads but at this point makerbot support is saying I need a new Mightyboard.

I have printed over 3000 hours with this machine and used it for several large prints so I know it is a capable workhorse but at this point I only use it for specialty filaments like ninja flex or ABS. so make sure your not trying to use both print heads at lets say .15 or .10. or 100 150…Oh and only use ABS on the rep2x or season your hot end EVERY time you load filament. and make sure you have the spring loaded extruders not the ones with the alan key adjustment (so bad)

I’ve replaced lots of wiring on the printer as well a gantry bracket and the nozzles and a bot step. probably more if I think aboiut it but I am definetly looking hard at the Ultimaker 3…

good luck

So I had a thought that if heat creep is causing the issues I should go back to a print that only uses 1 head, that way I only have 1 nozze+stepper generating heat instead of two. I do make it farther but eventually the head still heats up to the same level as before (110degC on carriage/mountingblock, 60degC at stepper.) Once it has reached the temp things start failing.

The attached image is telling. You can see how it lays down about 5 good layers then suddenly the noodle placement is all over the place. The noodle placement is still centered properly so I dont think it’s XY stepper/wiring issues (missed steps). It might be extruder stepper missed steps but I suspect I may have what this guy talks about in his blog post. This page is really worth a look-see for everyone…but the TLDR version is that he disassembles stepper from head, heats up nozzle and pushes filament through easily. Then he heats up the mounting block and starts noticing a lot of resistance.

http://www.makesea.com/wiki?p_p_id=54_INSTANCE_9jGVcyv6Jb3y&p_p_lifecycle=0&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=3&_54_INSTANCE_9jGVcyv6Jb3y_struts_action=%2Fwiki_display%2Fview_page&_54_INSTANCE_9jGVcyv6Jb3y_nodeName=makeSEA&_54_INSTANCE_9jGVcyv6Jb3y_title=makeSEA+Knowledge±+Printing+Magnetic+PLA+from+Proto+Pasta+with+Replicator+2X

I noticed during printing that at about the spot it started failing I could hear the guh-guh-guh of the extruder stepper slipping on the filament. Same sound as when it totally jams during loading but softer. Likely softer because it’s not feeding as fast as when loading filament. It was still feeding filament while it was happening though - I could see it…sooo…the extruder is definitely encountering resistance after heating up.

Image attached: yellow is bad layer, green shows good first 5 layers.

I would like to ask a favor, could someone who has a 2X and a IR or temp probe measure the temps of their head unit after a half hour of printing? I am curious how other units heat up. Something must be different from when my Replicator did work (for 12h prints!). I would be most curious what the Aluminum Carriage temp is at since it is directly connected to the thermal barrier which is where my problem likely is.

FYI I solved the heat creep issues by replacing the fans/heat-sinks with water cooling using a Koolance CPU cooling unit. Works great, mounting bar stabilizes at 43degC over hours of printing. More info at: