Hello All - long time 3D-printer, short time CTC owner and I am stumped - hoping yawl can help.

I have the infamous CTC dual-nozzle Black ‘Belzer’ and been trying for months to get a 20mm calibration cube - I have attached a PIC of what I wrestling with. This was printed w/PLA ~190C HPB ~35C and real slow 20mm/s & 0.20mm layer height

The side showing the boogie bands is always rear-facing edge. Doesn’t seem to matter what material (PLA ABS) or temperature. (clicking extruder cold to running water hot) o whatever I do.

It seems like the unit over-extrudes on the back edge only - like you can see the nozzle pushing the plastic up ~0,5 mm on the back only (!?!?!) (very noticeable)

I’ve tried everything I and others can think about except active cooling - different slicers, flow multipliers (SLIC3R), extruder K values in EEPROM, CTC 1.0 & Sailfish 7.7 firmware - nothing seems to make a difference.

Not sure if this is related but I find the bed height to be pretty inconsistent but I do (have to) adjust before printing.

My previous printers run Marlin and seen quite impervious to things like layer height and filament temperature but Sailfish is a different animal…(pun intended)

Thanks

I think it’s time to try active cooling. If your afraid of soldering the mosfet, just power it directly from the psu with a simple toggle switch. After the first layer, toggle it on. There are many different ducts on thingiverse that utilize a40mm fan. Ctc was kind enough to install a useless fan blowing on the stepper drivers. Remove that fan, it goes back to some original design flaws, and use it to cool the filament. If you are willing to spend some money, look for a duct that uses a blower fan.

Thanks - I was wondering that - I just thought active cooling shouldn’t be absolutely necessary - esp w/ABS and it’s propensity to warp!

I do have a v1 cooler printed just was a bear finding 24v 40mm fan laying around - now I have one - TY for tip!

But again, why should I NEED this? Never had to w/other printers and done some stupid things that never should of printed!

If you cant print out a “pretty good” cube without active cooling then you have a much greater problem than airflow. Dont try to fix a bullet wound with a bandaid.

Active cooling it what you play with for further improvements after you can already get an acceptable basic print free of mechanical issues.

What Slicer are you using?

The whole cube looks over extruded if you ask me…and not from heat if your only using 190c

Try re slicing the cube but add 10% to your filament diameter setting to see if you get any kind of extrusion improvements. Its a quick way to play with different overall extrusion settings.

Increase diameter for more less extrusion and decrease for more.

Also in the slicer place the cube 2cm forward of its current position to see if it yields a different result for that “back line”

Also slice the cube without rafting and take a close up picture of the 1st layer completed.

Then get back to us with results.

I used SkeinForge 50, SLIC3R and MakerWare for the slicers. I had tried specifying larger filament dia (or lower extruder multiplier in SLIC3R) but at 40+ mm/s speeds

But I will do you steps and get back to you with the results, thanks!

Look like over extrusion to me. This guide may help.

https://www.simplify3d.com/support/print-quality-troubleshooting/

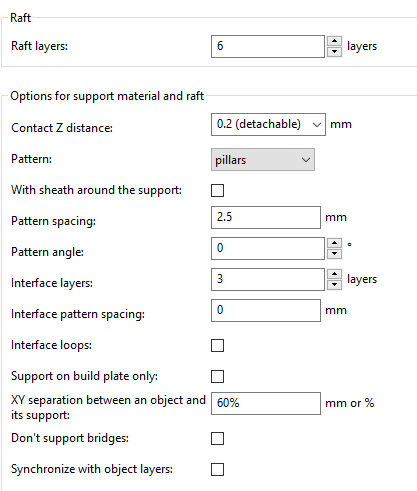

I’ve only used PLA on mine and have my build plate set to 0C aka no heating at all. I’m using the latest version of makerware with my move and extrusion speeds ~50 mm/s. I’ve attached my settings here. Hopefully it helps a bit.

This is great - thank you - I’d been looking for a pictorial troubleshooting guide for months!

I received my CTC 3D printer last night and successfully printed off the 20mm calibration cube on my first try using ReplicatorG. There was a bit of variance on my cube, about +/- .07mm, but I’m happy with that for now. I’ll briefly describe the settings I used.

After I loaded in my 20mm example file, I found some information online as to what temperatures are best for printing PLA. I generated my gcode and then clicked the gcode tab and manually edited the temperatures. I changed the hbp starting temperature to 50°C and the hot end to 200°C. I accidentally printed this first print at 80mm/s so the 90° corners were slightly rounded, but hardly noticeable. On my next print, I slowed down my print speed, used the same temperatures and I got an awesome print.

I hope this little amount of information helps. I’m obviously fairly new to the hobby, but I’ll attempt to help as much as I can. Let me know if there is any more information I can give you!

That’s great news Nicholas! Yea, my CTC was a lemon and it’s since been returned - guess I need to mark this a closed! Good luck w/your printer - sounds like you got a good one!