Hi everyone,

I have a problem with the branded Fairphone case. I use a Replicator 2. In my cases, we can see holes. They are always at the same places.

I use Simplify3D with these parameters:

Layer: 0.15mm

By writing and verifying my parameters, I perhaps found what is wrong…

Please, let me know if you had same troubles.

4 Likes

One more case printed with those parameters

Layer: 0.15mm

The problem is EXACTLY the same

Anyone could bring me some help?

Hi @GloomySparker , sorry to hear about this. Maybe @Joerg_4 , @NikolaiK , @HanCon , @Fab_Lab , @pixólido or @Philipbee might be able to help?

Hi there,

I use an Ultimaker, maybe the settings are different, but I do:

Layer 0.15 mm

Infill: 0%

Number of shells 2

Speed: 1800 mm/min

4800 is a very high speed, how long does it takes for printing the case?

Do you usually print that fast?

Also the infill part is so tiny that is useless adding a small percentage of material.

Hope it can help!

2 Likes

Hi,

I am printing on the Ultimaker 2 and I don’t have this problem. I am not familiar with makerbot, so unfortunately I cannot help in this case.

Nikolai

Thanks for getting back to us, Nikolai!

Joerg_4

November 20, 2014, 9:31am

7

Hi,

as Philip already mentioned you should change 3 Parameters:

Shells: 2

Speed: approx. 1200-1800

hth,

Joerg

Thanks @Philipbee and @Joerg

I printed a Technology Case with same parameters (infill 10%)… same problem.

In fact, I successfully used those parameters for quite long. Those params are those that 3DHubs is giving in the PDF. It took 4 hours to do the print…

I’ll try a technology case with the params you mentionned

Hi,

I´m afraid I will not be very helpful either, I use an Ultimaker and Cura, but I can tell you I print hollow with one shell using “spiralize” option (I don´t know if you have a similar one) at 0,15 mm and 25 mm/sec, while my usual speed is three times that.

Good luck!

1 Like

What are your nozzle width settings in Simplify3D?

Nozzle dia: 0.4mm (which is the real diameter)

Extrusion multiplier: 0.9

Extrusion width: 0.4mm

I printed about 10% of my print and it seems that you resolved the mentionned problem AND another one I was dealing with for a long time now.

My problem was to deal with retraction filaments. The back of the cases were messy at the end of the print. I had to do too much finishing (cutter and THF). For the moment, the filaments are only between the two end sides of the cover. It will be very easy to remove them using a cutter.

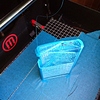

On the photo, you can see the current print.

I will come back with the final result for this print.

Thanks

That’s good. I’ve seen problem when you set the extrusion width on auto. The other obvious one is filament size.Have you checked that?

Sorry, I didn’t notice the extra images at first. The last one makes it look like it’s the number of shells that could be the issue. Try printing with 1 or 2 shells.

And if you preview your print, perhaps you can see whats wrong. is it printed concentric or rectangulair?

How many top solid layer do you us ? Reducing infill won’t help

James_2

November 20, 2014, 2:09pm

16

you should not be getting that stringing - the trick is to use single outline corkscrew printing - like drawing without taking your pen off the paper!

then randomise the remaining strt points.

I print at 3000 an it was fine.

And use a brim - otherwise it gets tricky at the top.

James

James_2

November 20, 2014, 2:09pm

17

oops - noticed you are using a brim

Launching a Fairphone branded case with your parameters (exactly the same) and I will come back to you in 3.5h!

Here is the result with these parameters… For the Technology case, the result is good… not perfect. I have quite a lot of strings and there are some tiny holes on the front side.

Then, I tried with the Fairphone branded case… As you may perhaps see (sorry for the quality), directly on the right of the Fairphone text, on the front side, you will notice many holes.

I am currently trying the corkscrew method (see below in this post).

James_2

November 20, 2014, 6:57pm

20

@GloomySparker reduce your print temp to as low as you dare to get rid of the stringing and help the bridging.

The slower speed should help with this - but it is a fine line as you need to get good layer bonds and yet good bridging.

I always had to do a small amount of hand finishing with a scalpel and wet/dry sandpaper, but you want to keep it to a minimum!

1 Like