The instructions (printed and video) indicate the use of two M2*12 threaded screws to attach the limit switches to the supporting acrylic piece. However, the screws are too short to pass through the switch body and into the acrylic to the depth required for the screw to “grab” / get purchase in the plastic. The screws came in the appropriately labeled plastic bag, and appear to be the only M2 screws, so I’m pretty sure I have the right ones. If I gently screw one of the M2*12 screws directly into the acrylic far enough to reach a grab point, and then position the switch alongside, it’s clear that the screw is not long enough. I’m hoping that there is a simple answer to my plight (like user error), but if anyone else has run into this issue and solved it, help would REALLY be appreciated. It chagrins me that this is blocking progress VERY early in the build. Thanks in advance!

gikam

2

All my screws and switches were ok. Which switch have problem? what is the thickness of your switch? can u post some detailed photos?

The only problem I had was too hard to screw and I broke the plastic support for x switch.; so I had to glue the switch.

The screw size was normal for the switch

1. Your instructions could be wrong. You could need longer screws. I had an Anet A8 and my instructions were both wrong, and the kit came with different sizes than it said. You might have more than you need in your kit, just use a longer one for this step and do #2 or #3 if you need to.

2. Your kit could have came with the wrong components, contact the manufacturer… or just…

3. Buy some longer screws. Buy a kit of them, you are likely going to want them for moving parts of 3D prints in the future anyway.

4. Drill a hole a few millimeters into the acrylic so that the M2*12 screw reaches.

gikam

4

on my Anet a6 all the switches are 6 mm thick. So a 12 mm screw is long enough.

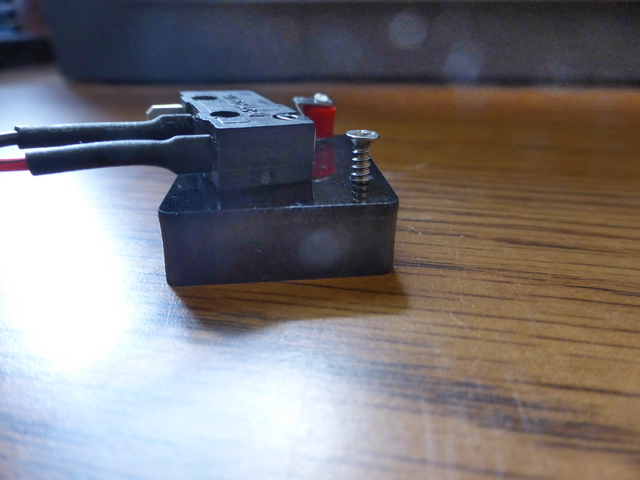

gikam - Thanks for the response! I don’t have a metric measuring tape, so the following are in non-metric units: Thickness of switch: 1/4in.(roughly 6 to 6.35mm). Length of threaded, cone-headed screw: 7/16in. total, 6/16in. to base of cone. I’ve attached a photo.-- I dropped the M2*12 into the hole in the acrylic, so you can see how far in it would need to go to begin to grab. I placed the switch next to it for comparison, so you can see the discrepancy between the length of the screw and what would be needed for it to work. If I can’t get longer screws, I might wind up following your approach and gluing the switch to the acrylic, using the existing (but too short) screws as alignment guides. That would be a last resort!

travisW - Thanks to you as well! I didn’t understand your suggesting to drill a hole into the ‘acrylic’, since the screw has to pass through the larger inherent hole in the switch to get to the acrylic, where the threads have to bite in. If you were suggesting drilling a little ways into the =switch= so that the screw could go in deeper, and thus reach the acrylic with sufficient threads to dig in, I agree with your thinking. I tried ‘countersinking’ just a little, but was reluctant to go deeply enough for fear of destroying the switch. As you pointed out, I suspect I’ll need to find longer screws. (Have to wait until wife gets home with the car!)

gikam

6

wait

which switch are we talking about? x,y, z?

Y-axis. (Though I would expect to run into the same issue in each case, given that all three switches look to be the same – just different wiring lengths.)

gikam

8

OK

Now i see where your problem is.

That’s a piece of plastic support which is fixed to the chasis with a single M3 screw, right?

The problem is: the hole for the M2 is too large!

I suggest to fill the hole with a plastic soldering gun or glue the switch, since it won’t affect the assembly, or use some wire to tie it tight, or find a longer screw. Or (not sure; u have to measure to be sure) u could drill another 2 holes (1.7-1.9 mm diameter) a few millimeters to the left of the ‘bad’ holes. (drill in the acrylic)

good luck

gikam - Thanks again. Went to stores for longer screws, but not obtainable here. So I’m going with “Plan B” and filling the hole part way as you suggested. I haven’t worked with a “plastic soldering gun” =or= a “hot glue gun”. By the former were you talking about one of the approaches that uses UV light to fuse a liquid substrate? I have some of that, but haven’t gotten around to even trying it yet, so this might be the maiden voyage. If you were thinking about “hot glue gun”, I bought an inexpensive one and have that available as well. PS: I’m chagrined to say that only today did I realize that the holes in the acrylic – into which the threaded screws are supposed to go – actually go all the way through. So just a longer screw might not have worked anyway, though the taper of a longer screw might have been just enough to do the trick. School of hard knocks knowledge!

gikam

10

I just got started building my Anet A8 and have the same problem. I used the smaller of the supplied screwdrivers to bore out the holes in the switch a little so the screws would get at least a little traction in the acrylic. I believe there are mods around for moving the limit switches. I will definitely be looking into those.