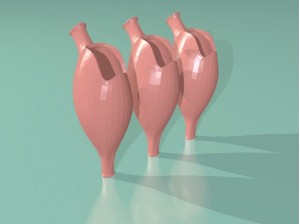

A beautiful small sculpture by designer lara behmoaram.

Preparing for Printing

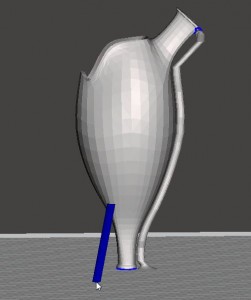

The supplied model is a single file containing 3 identical parts. We will split this up because we’ll run a test print first and we don’t want to triple the risk and potential waste. Meshmixer is the ideal tool for this.

The orientation of the model is fine and it looks perfect for FDM printing, except that there is not a lot of contact area with the build plate. a brim will be added by the slicing software, but that will likely not be enough, so while we’re in Meshmixer, we’ll add some custom support.

And now we have a printable model with a low failure risk using @ColorFabb recommended settings for bronzefill:

- Layer Height 0.2

- Fill 100%

- Speed 50mm/s

- Bed 60ºC

- Nozzle 220ºC

Finishing Bronzefill

Removing the supports

The Meshmixer supports remove very easily, and any support artefacts can be gently filed away. After polishing the models any remnant of the supports will be gone.

Lara is happy to do her own finishing on this occasion, and being aware of the tessellation in the model, she is not yet sure what her preferred finish will be. To give her a few ideas of what to expect, we print an extra model to test the finishing on.

Steel wool

First off- a rub-down with steel wool very quickly removes the Course MDF-like matte finish, and really shows up the tessellations in this case. This result is after a couple of minutes at most.

Spit 'n polish

Now a little elbow-grease!

The finish at this point is beautiful, with the tessellations making a wonderful contrast to the flowing shape of the object and they catch the light nicely- the picture here really doesn’t do it justice.

But there is one more step…

Sanding smooth

Using 360 grit Wet & Dry sandpaper with the aid of water to prevent clogging, we polish out the tessellations and any remnant of print lines. this is a lot easier on the gentle curves but naturally takes more effort to get around the sharper curves and crevices. This is worth bearing in mind when designing or perhaps smoothing a scanned model. We could possibly have gone a little courser -240 grit - to reduce the effort required, but ultimately after another round of Brasso, the final finish won the day.

See them side by side, which do you prefer?

See the original post here.

created

Mar '15last reply

Mar '15- 10

replies

- 1.8k

views

- 8

users

- 3

likes