High quality is our top priority

We strive for excellence in manufacturing. Every part produced through our network meets the highest standards and we’re constantly raising that benchmark. We never settle when it comes to quality and we design our quality management systems so we never have to.

Protolabs Network is AS 9100 D / ISO 9001: 2015 certified and additional certifications are available through our manufacturing partners.

Introducing The Protolabs Network Standard

Protolabs Network’s quality management system helps us deliver parts to spec. We maintain operational excellence across our in-house teams and vetted network of manufacturing partners (MPs), ensuring on-time delivery and low dispute rates. All of these processes, qualifications and systems form The Protolabs Network Standard.

A manufacturing network with limitless capacity

Our network of hundreds of manufacturing partners (MPs) provides virtually limitless capacity and specialized capabilities. Using our platform, you can easily consolidate, simplify and bolster your supply chain at competitive prices. MPs have to meet a rigorous set of standards to join our network and we maintain their quality through live performance tracking and quick-turn corrective action plans.

Every custom part meets The Protolabs Network Standard

Working with a global network of manufacturing suppliers gives us our breadth of capabilities, but it also requires us to manage certifications and standards on an international scale. To maintain consistent quality, we have comprehensive quality processes for every part that flows through our network. These processes form The Protolabs Network Standard.

Read all about quality control

Putting The Protolabs Network Standard into practice

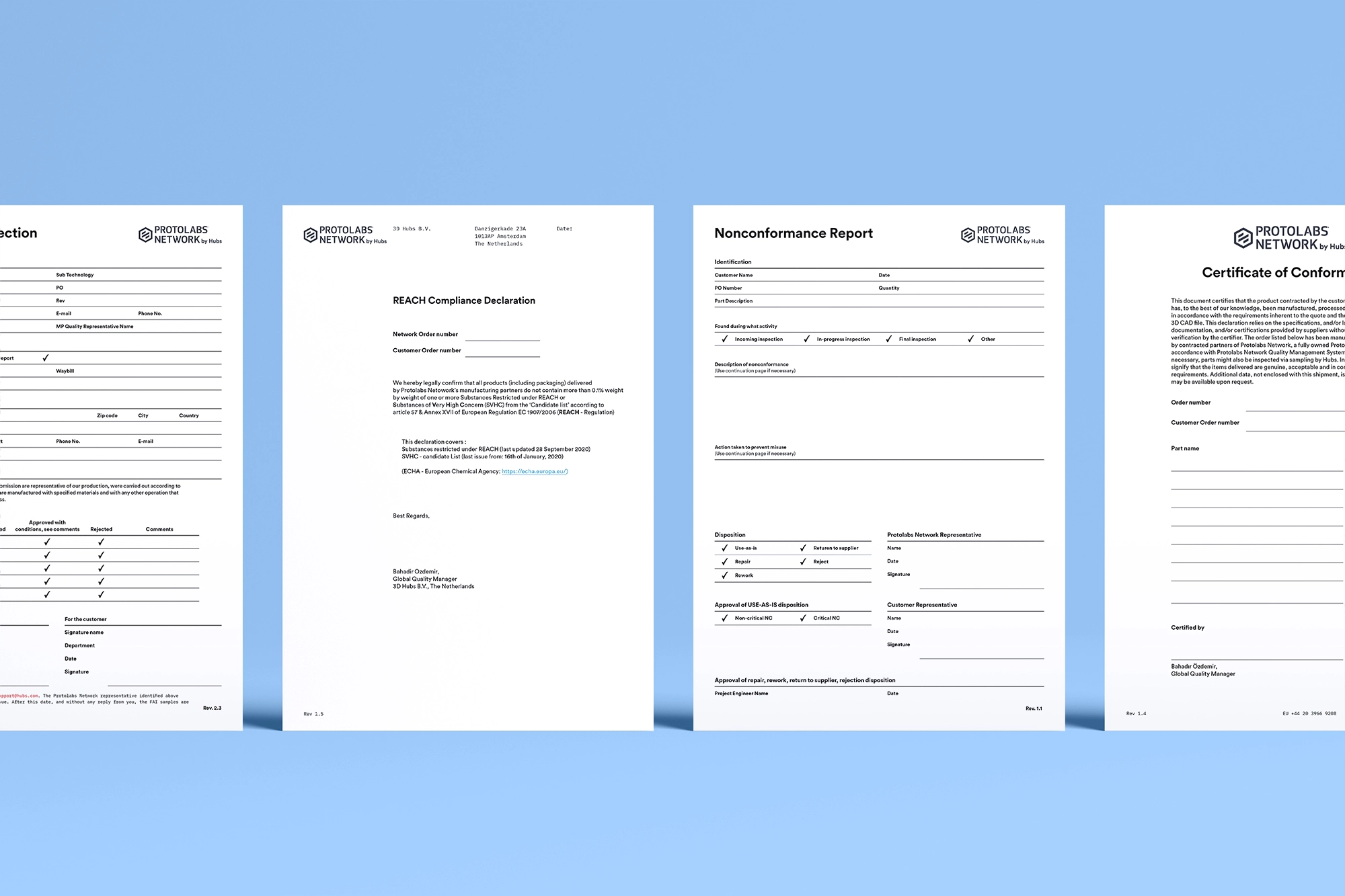

Protolabs Network is ISO 9001 certified and we can provide essential documentation like CMM dimensional reports, REACH and Certificates of Conformance upon request. We make it easy to trace orders from quote to delivery and our Customer Success Team is always ready to rapidly resolve disputes. And because manufacturing never stops evolving, we frequently audit our systems to guarantee quality, every time.

Protolabs Network is ISO-certified

We can certify your parts to the following industry standards: ISO 9001, AS 9100, ISO 13485, ISO 14001 and ISO TS16949. It’s always possible to have your parts manufactured with industry-specific certifications. To find out more about Protolabs Network’s certifications, contact your account manager or email networksales@protolabs.com.

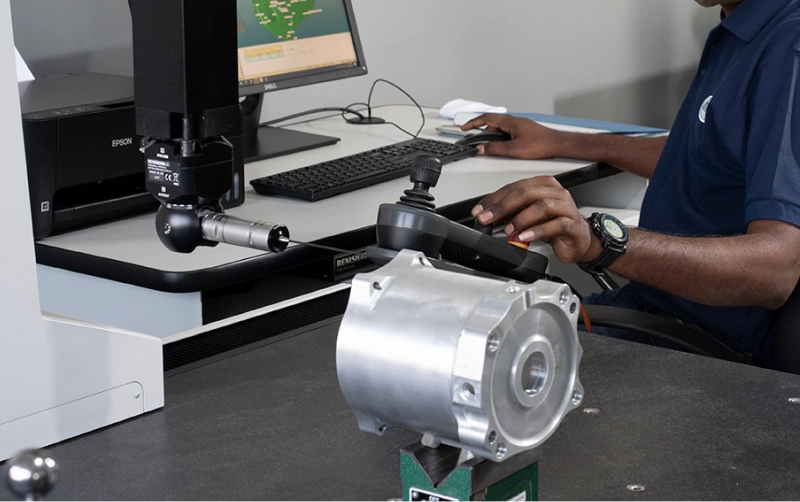

Cross-docking to maintain quality standards

Protolabs Network has two specialized cross-docks at our Amsterdam and Chicago offices where we perform extensive quality control checks. Here are the main checks we do on-site.

Learn more about The Protolabs Network Standard

- ISO certifications

- Selection

- Onboarding

- Audits

- Performance tracking

- Cross-docking for quality inspections

- Packaging inspection

- Document review

- Non-conformance correction

- Complete reporting available

- Certifications and documentation

- Vetting the MP network

- Handling disputes

- Systems for maintaining guidelines

- Comprehensive manufacturing standards

Your parts are in good hands with us. Start a production project today.

Get an instant quote