Tareq, we are using M200 Zortrax 24/7 literally as we are running our productions on them. V4 is the latest Zsuite Application (not hardware as someone wrote). It is application translating .stl file into specific Zortrax Z-Code (think as the Gcode) to slice and place model on the bed. V4 is the latest version and have some very good features like PAUSE (you can pause print at the specific layer to change filament color (we tried it, works great), calculating print cost of the model (available since previous release), new materials (PCABS) and few improvements to speed up print generation. If you are buying printer and there is no v4 with it, no worries, using printer serial # you can logon at ZORTRAX web site and download for free latest version. Remember to download and update microcode too.

Happy printing.

Can I ask where are you located?

Best

Kuba

kuba@paliproto.com

I have every colour of filament for Zortrax z-abs, z-ultrat, z-hips, z-glass, z-petg and they all work great, almost as good as my sla machines.

I have many materials for Ultimaker and again work great.

If you only want to build abs parts Zortrax is the best.

with over 11 years operating large SLA, FDM, and Connex 3d printers i would say both Zortrax and Ultimaker are very good value for money.

Paul

www.pbmodelmaking.co.uk

www.LaserLayers.co.uk

There are different versions of the printer, though subtle it may be. Thats why you have to pick the version you have when you use Zsuite.

From a Zortrax user:

“The V1 and V3 have ball screw on the Z, the V2 have lead screw on the Z. I have both versions, and at the beginning was a problem with dimensional tolerance with lead screw, they solved it in the software so that’s why you need to choose HW version in the ZSuite.”

For the record, there are no HotEnd v3 and v4. There are v1 for regular Z-ABS, Z-HIPS and Z-Ultrat. HotEnd v2 for Z-Glass, Z-PETG and Z-PCABS, plus everything what v1 is capable. In addition ZSuite is not defining HotEnd, but it is allowing to chose material during build.To be clear v1 is still good with v4 ZSuite as long as you chose proper filament.

Best

Tareq:

Good day to you. I am a Zortrax owner/user. In fact I have (2) two M200’s. V1 - V4 are version numbers of the machine . My machines are both V4 units. As far as a recommendation goes “I love my machines”. I would waist my time on any other machine. But, that is me. You may have different needs, wants and desires. Please advise if I can be of more help. I am also a 3D Hubs member. I hope you have a great day and make the right decision in your purchase.

Hi Tareq!

It is different hardware versions. You check it in the meny on the display of the printer and choose the right version in

Z-suite.

Not a big deal, i belive.

I use my Zortrax M200 every day nearly and it is working great.

The prints are top of the line!

Best regards

Svante Sandberg

3d4you

21

Hi,

as already mentioned, zortrax is a very reliable plug n play machine. Very good quality. But only zortrax materials should be used. 3rd party abs may work. Nothing to set. Not even print temperature. Good choice if you want print results.

Ultimaker is open source and much more flexible. Can print various materials. Many settings. Some can be changed even while print is running. Good choice if you like to play with it. Quality can even be a little bit better than zortrax, but printing slower.

On www.3d4you.net both machines can be tested.

Hi Tareq!

As these helpful members mentioned, there are software updates and a couple hardware changes (v1-v2 hot end) however, what has not been mentioned is that there were multiple hardware changes to

1. the extruder cable

and one change to

2. the perforated build plate (thicker)

So in reality it is not just a software change, some of the hardware does change from v1-v4.

I have absolutely LOVED using the Zortrax m200! So much that we started reselling them!

If you have any more questions regarding v1, v2, v3, or v4 of the printer, please email me at:

service@protoripe3d.com

We would love to help you gain information so that you can make a great purchase!

Cameron

p.s. check out the pictures to see the differences…

With an after market Z-Temp addition to the Zortrax M200, it can print any material that is on the market.

I have found in my business that I have had some with Ultimakers that needed a quality print, hired my M200 to print it for them. I am sure the ultimaker can do quality but with so many tweaks needed to the settings to get that quality print, I wouldn’t even attempt to delve into that world. lol

http://www.3dzprinting.com

Hi Tareq,

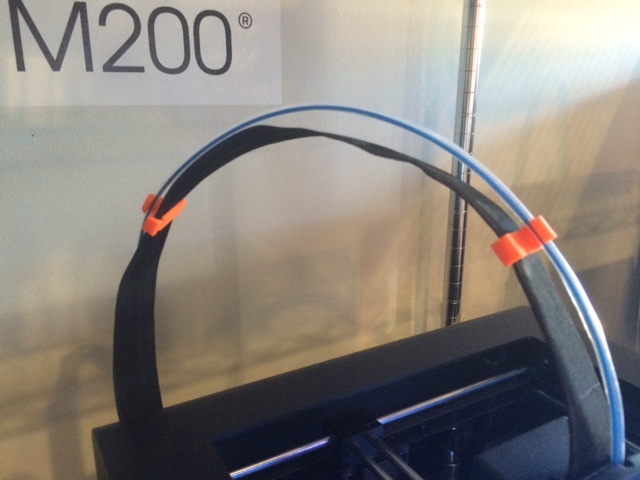

Zortrax is a great printer and if you need to have reliable printer, with filament formulated for the specific printer for the best quality prints and don’t want to spend time on thinking about parameters and settings - buy M200. After reading all entry, clarification is needed as folks mixing software, microcode and plain hardware. 1). Z-Suite is exactly 1.4.1.(commonly called v4), printer had 2 versions, first at original Kiskstarter with rounded extruder cable, quickly replaced with flat cable (by the way you should print kit keeping extruder flat cable and plastic extruder feeder together to prevent cable being damaged - see attached picture). 2). Both HotEnds v1 and v2 are supported by Z-Suite 1.4.1, both plates v1 (thinner) and v2 (thicker) are supported by Z-Suite 1.4.1 3). M200 hardware and functionality changes are driven by new microcode, again nothing to do with Z-Suite as software is compatible with new and “old” hardware, microcode is really much more important to be current…

New plate is better in preventing warping (model and plate itself, made from aluminium) and is more evenly heated. New Z-Suite version is solving bugs, changing some functions available during slicing, adding more precise slicing algorithm etc.

New microcode is adding new function like filament load and unload, time of print, progress and so on visible on LCD screen. yes, you should have latest versions of ZSuite and Microcode, but if you can buy older without at bargain price, go for it as every thing you can download from Zortrax web site. Confusion is created by some of the distributors, resellers as they proclaimed different version of Printer by bundling HotEnd v2, Plate v2 and sometimes side covers together and selling it as v4 or “Professional”. All parts can be acquired separately and assembled into your printer, again nothing to do with Z-Suite.

Base printer in US is around $1,990.00, other elements varies. New printer generally are shipped by Zortrax with HotEnd v2 and plate v2 and side covers can be purchased separately, as they help preventing model warping.

if you have more questions please let me know

Kuba@paliproto.com

I got my M200 from Kickstarter and as you can see from the pics, it has a flat cable. I have never heard of a M200 with a round cable.

austweb

26

I own a Zortrax and what your talking about is Firmware that runs the machine, always get the latest version of software and firmware, that way your kept up to date.

As far as the Zortrax Machine goes, I cannot fault it, I have had it running for a year now and no trouble at all, compare a Zortrax to an Ultimaker, I would not put them in the same bucket, Zortrax to me is superior, Industrial grade Prints that I cannot fault.

I have several machines from different makers and about 6 of my own built, Zortrax stands above all, I would have no hesitation in buying a Zortrax over any brand.

Other Filaments can be run in a Zortrax, but you need an add on from :

It is very good !!!

HB3D

27

Hello,

The differences are in the extruding and the nozzle. This printer is really a professional because very precise level : 90 microns.

The update is very followed by the manufacturer and provides access to a pro library.

The machine is reliable. I have no problems over one year long.

I recommend zortrax for Professional prints

I thought at some point they had wifi in version x. I know they also improved the platform between certain versions. I have the latest version 4. It’s the best printer I had by far. I had a RepRap and Form 1+. The Zortrax has been printing for over 20 hours now without a single problem.

Tareqq8

29

Thank you so much

i have received new one v4 great yet . but i need more choice

what about Z-Temp any one used ?? good idea ?

Hey, congrats on the printer, your going to love it.

As for Z-temp I’ll say this. I own two M200’s, one has the Z-temp. I’ve had the printers for over a year and I waited till my first ones warranty ran out. My main reason for the year though was just to get experience and learn the machine. I’m not sure if this is your first 3D printer but if it is I would certainly wait a little before worrying about Z-Temp.

It seems like a great tool but really you will be able to print anything you need really with the regular machine. Only thing I wish I had was the option for ninja fled but z temp can’t even do that.

Ill ll also add I’ve not had very good luck with the z temp. I’ve only tried using it a few times and the material I’ve tried isn’t very highly recommended so it’s not a great example. I’ve spent probably more time taking the hot end off and cleaning it then I have printing.

Ztemp is awesome! I use mine all the time. It really opens the M200 up to all possibilities.

Julia_1

32

Your suggestion to gain some familiarity with the printer before venturing into third-party materials is a sound one that I agree with.

As for “being able to print anything you need” without a Z-Temp, I would respectfully disagree - you cannot print any of the myriad and wonderful PLA, nylon, or tree-lignin based materials out there. Warping is an issue with all of the Zortrax materials, and pretty much a non-issue with the others. I’d owned my first M200 for a year before developing Z-Temp (yes, I’m the developer) and printed a boatload of ABS and UltraT with it - now I almost never use it because PLA prints so beautifully warp-free.

As you note, not all PLAs work well, but more and more compatible ones are appearing on the market all the time. There’s a complete guide to what works and what doesn’t at http://www.z-temp.co/materials-guide.html.

Regarding nozzle clogs, it’s simply a matter of being sure to run a few feet of material through the nozzle at full temperature whenever changing to a lower-temp material. I haven’t had a clog in many months.

As to Z-Temp “not even being able” to support NinjaFlex, that’s nothing to do with Z-Temp - the design of the M200’s feed system, with the feed gear several long inches from the nozzle, precludes its working with rubber-like materials. You can’t push a wet noodle! Taulman PCTPE, however, works great and while not really rubber-like, can provide flex for many applications.

2 Likes

I have to disagree to an extent on your results. Have you printed with the v2 nozzle and plate? I am able to get full build size prints with zero warping. (ABS and UltraT)

Also a little bit of slurry does help with that. I will get a few warped parts but that usually due to the middle being .02 off from the rest of the build platform. This means that the build plate needs taken apart and cleaned then back to printing.

I can confirm that the Zortrax M200 has an enormously high print quality and we printed even defect-free parts which the printout lasted over two days.

We can be excited about what brings the new Zortrax Inventure with its monitored material consumption!

think it | print it | like it

www.iprint3d.ch