You can use them, but warranty will be void.

If you want to experiment, buy some other machine. the M 200 is designed for Z-Filament series.

The fact that it can “work” with any other it’s just because maybe that particular filament is in the same range of Extrusion temp. But it doesn’t mean that it will perfom ok.

The Z-filament purpouse and concept is to offer customers high quality product, and a certainty on chemical and mechanical properties not like those “other” filaments, Actually very limited manufacturers test and provide information related to this properties.

For fabricating “maker crap” you can use any cheap filament. For producing high quality results, several alternatives are available, aside from Z-filaments like colorfabb, Orbitech, Ninjaflex, etc. none of them cheap.

Hi Guys,

As pointed out by others, the Zortrax uses it’s own proprietary 1.75 ABS filament (although other “Z” materials are available. The quality of the Zortrax filament is extremely good although it prints at much higher temps than other 3rd party ABS filaments. It prints as much as 20-30 degrees higher than most (typically around 260). By using the correct Z-ABS, removal of support is a walk in the park. When you print with other filaments, although it may work, the support will be bonded much stronger to the print which may may removal a lot harder.

Allegedly (LOL) the filament that UP! supply uses the same nozzle temperature and (allegedly) it prints identically with perfect support removal. To be honest the UP! genuine filament isn’t really cheaper and it has nowhere near as good a range of colours compared with the range offered by Zortrax, however it is more widely available in the UK.

As others have said, certain materials aren’t available as official “Z” branded and approved materials. For this reason, the print profiles similarly aren’t available.

There is soon to be a commercially available 3rd party plug-in mod to be released which will provide the ability to change extrusion temperature which will be a really exciting prospect for many Zortrax users. Use of any mod would of course void the warranty (which to be fair to Zortrax has been a VERY good warranty for me).

I would say one thing though, printing with Zortrax filament is virtually bullet proof. You can load a file, walk away and know that a 24-36 hour print will complete without you having to nurse the machine through every hour of the print. The material profiles are exceptionally good. It’s why I LOVE the Zortrax. Although the ability to print “alternative” ABS or materials at lower prices is a wonderful plus, it will of course mean that in some instances, printing will revert to being less predictable or plug and play.

I have an UP! Plus 2 printer as well as the Zortrax and to be fair, although I have a temperature mod for it, I don’t actually print anything other than genuine UP! (or Zortrax as they’re so similar) filament for the majority of the time.

Cheers,

Jay

The warranty void is a bullshit thing. Yes they claim that without being specificaties. But in the end it can only voor The warranty on your nozzle, which has no waranty at all. And on The makercrap: my customers were not satisfied with the too yellow white from Zortrax. So I printed more than 800 parts in non Zortrax filament. Customer satisfied and I earned my printer back twice. Yes Z-abs creates beter removable support. But sometimes there are good reasons to choose other filament. If you are afraid of warranty void just keep an extra nozzle…

Hi Jay,

The meaning of my answer was to understand if it was possible to print with SPECIAL FILAMENTS ( woodfill or bronzefill) rather than with cheaper alternative ABS or PLA.

You can try but unless you change the firmware of the machine theres no way to adjust the printing temperature on the M200 and each type of filament needs heated to a certain temp to properly print. The Zortrax M200 filament is designed to be a bit different then normal filament to add proprietary for exclusive use. You can try different loaded parameters on the Zsuite and test other filaments with it but don’t be surprised if they don’t print right.

Eventually all types of filaments (wood, metal, flex etc) will be available for the Zortrax M200 but as of yet they are not available. I believe they are working on Z Flex right now and fixing an issue with Z Glass.

I have heard of success with some different ABS filament but they don’t print as nicely as the Z ABS.

Good luck with it and if you succeed, please let us know.

vT3Dv

20

Unfortunately this is not possible because you can not change the temperature setting of the extruder

1 Like

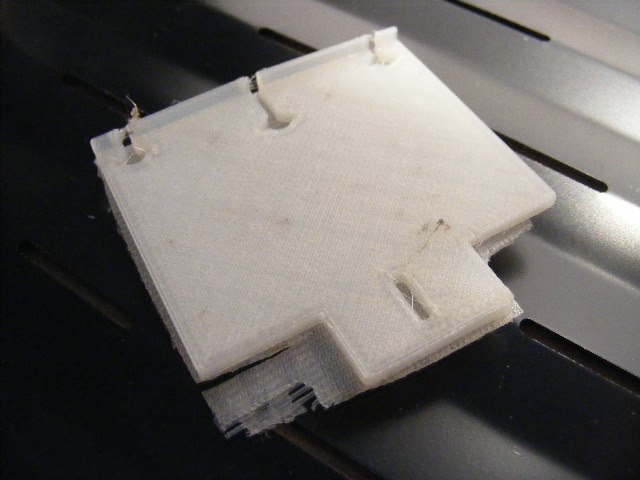

A bit of modding can be done to the machine like putting a resistor between the thermocouple of the extruder. It really would not be too difficult to do and will work with normal filaments. I have used some super cheesy filament for $20 at my local microcenter (the unbranded stuff) and have been able to get great results. The raft and supports came off just as easily as the regular material but was a bit too hot causing bridging to droop and did smoke just a hint when printing. If this was lowered any abs would work perfectly with the zortrax, and the prints that I was able to do came out great.

The Z-Temp™ is now available, providing Zortrax M200 users with extensive control of extruder temperature, visual display of actual extruder temperature, and output for measuring extruder temperature accurately, and the ability to disable bed heating.

www.z-temp.co

5 Likes

So what filament did you use any brand in particular or a specific type of filament ?

The formfutura filament. It has a high printing temperature. Just testes another roll: easyfill white. It is really opaque white, i had been searching for that for some time, prints good. Before I used frosty white and pink from formfutura.

Hi guys, Oo-kuma ABS Works like charm on zortrax, in my experience much better than its own grade!

especially their carbon-fiber abs content is very good to work with zortrax.

cheers, arda

Great idea for the m200. Have it my self and it works great easy to install!

Nice work Julia! This takes away the single imperfection of the M200.

Cicio

28

Hello everyone, avet eprovato printing the filament flexible? obviously with the form Z-temp

Hello it is possible to print the PLA with the M200 . just use the parameter Z- Glass in Zsuite . I also use a lot cheaper than ABS Z- ABS (http://www.machines-3d.com/filaments-resines-abs-machines3d-xsl-367\_413.html) . A printing it releases a strong odor, the print quality is similar to Z -ABS

1 Like

you mean to keep an extra nozzle or you expect to need a extra hot end?

Thanks for your help.

I would like to try it, but little affraid of it

These ABS filaments print very well with Zortrax M200 printers.

Printer with Taulman PCTPE goes very easy with this setting but I get not the raft off

Does anyone already have a solution for this?

Zortrax M200 - Z suite 1.10.0

ABS base materials configuration

Nozzle: 230°C

Bed: 70°C

Layer: 0.14mm

I know this is an old thread but just in case someone stumbles upon this as I did. Zortrax has opened their machines to third party materials. Z-suite now contains the option to switch to third party materials and make adjustments such as speed and temp.

4ndr34

34

Hi,

now with the new z-suite you can use also others filaments brand and type. In the advanced settings there are many opened parameters. Just try them