Thanks for the upload,

That is weird. Let’s try this…

Disconnect power, take only the working motor and connect it to a different motor connection. From the configuration.h file it looks like you have a RAMPS board. So if it is X move it to Y or Z.

Leave the other motors including the extruder disconnected and try to move that motor using the control for that axis you hooked it to. If it works,move it to the other non-working axis. I’m pretty sure the extruder motor won’t work until you get to minimum temperature with the hotend, but don’t worry about that yet, we are fixing X,Y,Z for now

If both axes work using the “known good” motor that shows the drivers are functional. Now it’s time to connect the “non-working motors” one at a time to make sure they work.The orientation of the connector on the board will just reverse the direction of the motor when it spins. Just take a look at the color sequence of the wires on the working motor and make sure the non-working ones are correct…

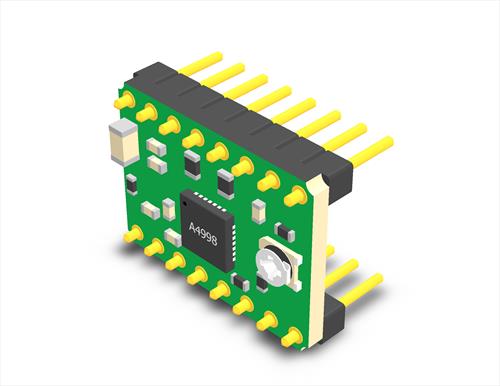

Here is a pic of the A4998 driver chip for your stepper.

That is usually the one they ship. There is another type that is more robust but that is usually an optional thing. The round shiny circular metal object on the right is the potentiometer, See if they are all set “roughly” to the same orientation as the “working” one. Without a meter that is a rough guide to get them close but not completely accurate .

I don’t want to overload you with things to check, it would be better for you if you had somebody with a 3d printer that you knew who could give you “hands-on” help, It’s tough to diagnose over the web.

If the working motor does not move on the non-working connectors it could be the driver board itself.

Here is a pic of the RAMPS board with the driver boards.

Is that what you have? The stepper connections are above the driver boards from Left - X Y Z

from top Left Extruder 0 Extruder 1

If it came with 5 you have a spare driver board.

Let me know what happens.