Thanks - it’s hard to beat 99 pounds ($129US) each! I have wasted at least that much and more in my time. I’ll send them a note and see if they can do this kind of thing. Thanks for the link. -J

Yes, please: Thank you for the private message.

Thanks for the input. We half-tried the alcohol but the job wasn’t monitored and the alcohol dried up while it was soaking (bad but maybe not catastrophic). We re-hydrated with more alcohol, reinstalled the heads and I’ve been doing head cleaning and pattern checks. I haven’t run a weight test (aka load cell calibration) yet but it’s on my list of things to do. I just found a video on line for it; thank you YouTube! -J

snrp

20

I’ve been running an Alaris30 since 2010, and only had to replace one head this calendar year. Since I only run VeroWhitePlus, I can’t speak to the Durus materials, but my practice has been to more blot with a denatured ethanol dampened cloth, with about a 30 second soak against the heads.

When the one head failed abruptly following a crash, I tried to resuscitate it by flushing it with alcohol, after removing it from the machine. This was not successful, and actually demonstrated a negative result. Consider trying the the ‘solvent’ they sell for long term storage. It’s actually a base like the support, without the curing agents.

Good luck!

Hard to make out from the images exactly, but I was told the print head will need replacing if:

Up to 5-7 nozzles blocked in one place MAX.

Up to 12 nozzles blocked in total across one head.

You can fit the print head yourself.

The printer overlaps the print pattern to compensate for some blocked nozzles, but if more are blocked than detailed above this will have an effect on the parts.

Thanks for these good ideas. Our heads were swapped about a year ago so I think I might have some Durus model material gunk in either head so I have to do the heavy-duty cleaning on either/both. We half-tried the alcohol but the job wasn’t monitored and the alcohol dried up while it was soaking (bad but maybe not catastrophic). We re-hydrated with more alcohol, reinstalled the heads and I’ve been doing head cleaning and pattern checks since then (about 2 weeks). Unfortunately, they’re printing worse than ever now. I have some NaOH here from when we had a Stratasys 1600 SST system (soluble support meant we kept a bath of NaOH for dissolving it). Hopefully it can burn away any of the old gunk and new gunk. It is tempting, however, to pack them up and send them off to the print head recovery company… For $129 (99pounds) each, it seems like they know what they’re doing and I’m just fiddling around. Thanks for your input. So, you don’t expect the NaOH to burn up anything on the inside of the head? I could try using a syringe to push it through the ports… or, we could pay those nice people to do it. Hm. Decisions decisions. -J

1 Like

Hi Julianna,

I have limited experience with the objet, so I can only speak from observation. First question/comment is that im surprised you dont have it on a service plan. If you’re getting such a low use out of the heads, maybe you should contact stratasys?

how are you identifying that the heads are failing? aka what led you to believe that thats the issue

thanks

1 Like

Thanks for writing this note, Pavel - you are making good points/ asking good questions.

OK, so we do have a service contract - BUT it doesn’t cover “consumables” and the heads are considered consumables. A tech came out a year ago and swapped heads (model-support) and that bought us more time. Thing is, they didn’t really give us great detailed instructions about how to clean the heads. We/ I thought I was following the directions but without proper training, the interpretation is wide. Plus, starting 6-mo after we got this printer, we used Durus material and it appears that Durus is harder on the heads (aka it gunks up faster) compared with Vero. The service contract NOW contains a once-per-year training and maintenance visit. That would have been great to have gotten last year.

The two main reasons why I think the heads are the problem are: (1) the July-service contract tech says so and (2) because the prints are bad (even on things that used to print fine). From knowing what the stl and solidworks model looked like, I can see where the support was meant to print and instead the model material above it has sunken down in the spot above it. I used to be able to print a whole bed of these small knobs and then a few months ago, I saw them “sinking” - the support not showing up most of the time and the model material blobbing down as if it were deposited but fell to the lower height since the support wasn’t there. One time this spring, I printed a whole bed and the parts were basically glued-down - no support, just model material straight on the print bed. I chipped them off and I’m very impressed that I didn’t scratch the print bed (which I believe is only aluminum) with my steel scraping tool! The tech that was here did a load cell calibration in July and said that the heads are bad but that he’s tried to get as much as he can out of them - I take that to mean he’s increased the voltage to the drivers/actuators that push the material thru and he said if we keep doing this, it will become erratic. I haven’t done a load cell cal yet myself - it’s been a month and we did a soak in alcohol since the last one. It’s on my list of things to do but I’m not looking forward to “erratic” behavior.

I took some photos and I’m due to post another note with “before” and “after” for the model/stl and then the real thing. It’s bad - you might want to get some tissues ready!

-Juliana

Juliana,

we had a similar story. turned out the z axis motor was gunking up or something.

I’m not sure how it relates to your situation, but our tech spent sometime until they figured it out.

Sean 6104768060

1 Like

Thanks for this idea, Sean. Never even thought of it. It is possible that some stuff got in there.

Do you recall what the test would be to check the z-axis motor? Thanks. -J

J

sorry for being confusing. I am Pavel.

Shawn is our tech that figured this out for us. And I honestly have no idea how he did it. I can get his email if it is easier than phone for you.

but ultimately, he opened up the machine and was watching the z axis rod rotate. that i do know

Hi Pavel - I would be happy to get an email or a phone number to see how your tech figured it out. Maybe he saw it slipping. Hm. Well, just knowing that a z-axis motor (which is covered in our service agreement) could be the problem is helpful. Thanks for the PM and for your help! -Juliana

Hi, you can take the heads out, make sure not to loose the small seals on each side, than you can put the heads in isopropanol and also fill the inside with isopropanol, leave it overnight , make sure not to damage the electronics and cover the isopropanol bath so it does not get evaporated over night, than blast with compressed air, if it is not better than you have to go for new heads, I am running an Eden 260 for more than 6 years, good luck

1 Like

Use pure IPA (isopropyl alcohol). Put it in a syringe (10 ml) and put a 1cm long rubber tubing instead of the needle. Remove the heads and clean them first with IPA (don’t forget to wear nitrile gloves, of course). Be sure to have pure IPA and clean (never used: no particles inside). Then, flush the head with the syringe through one of the holes on the head (where material refills the head usually), but don’t forget to close the other one with your finger (wear clean nitrile gloves for that) or you’ll have IPA in your face… Do it as long as the nozzles are clogged (typically 2-3 times).

Good luck!

1 Like

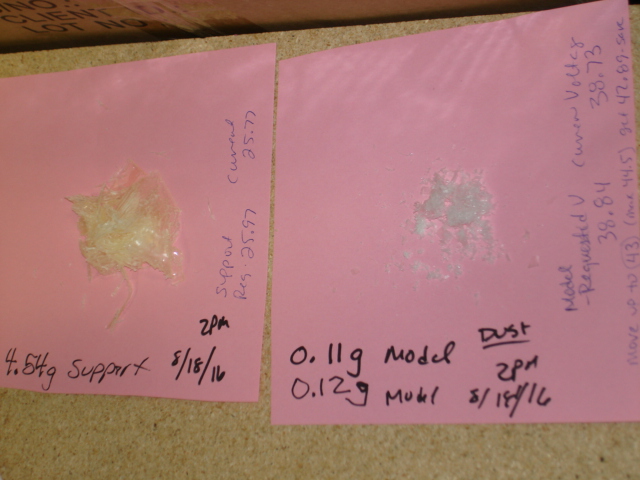

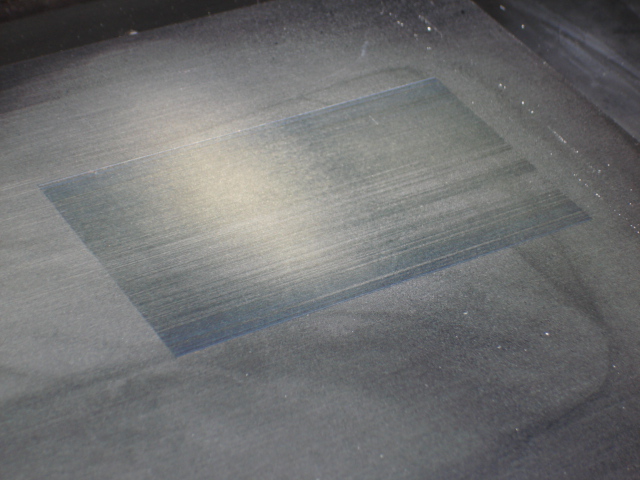

I took these photos almost a month ago and never posted them. I tried increasing the voltage to the piezoelectric controllers. (They are what control the opening and closing of the little doors that allow or restrict the flow of the uncured material.) The tech had the voltages pretty high and I just increased the model voltage to the max. Then I ran the weight cal test and it asks the printer to print 4 or 5 grams of material. What I got from the support head was close to what was requested. The model head just made a thin layer which I scraped off and weighed. It was just dust really and nowhere near the amount I want. The model head is BAD. Now, I’m just waiting for the $ to get a new one. Once we have a new one, I would like to try cleaning the old one with the methods described here but for now, I’m learning to live without a 3D printer. So sad… sniff, sniff! Thanks for all your help, 3dHubs. -J

Hi, I am a new user here and I was wondering if you had success with any of the cleaning methods in this thread? We are having the exact same problem and are also waiting on the $ to buy a new one as well so I thought I’d ask. We are on our first set of heads still so we can’t take one out and send it out to try to get it cleaned or we’d be leaving the printer idle too long.

Thanks and I look forward to your response! -EB

Hi EB. Well, I’m not sure this is going to be the standard answer, but… a few weeks after I posted this, my boss got on the phone with our 3D printer support/ reseller company - the people between Stratasys and us. I don’t recall the phone call being particularly loud or anything but a few weeks later, a new head arrived and we didn’t pay for it…! A few weeks after that, I was at a training event with our support people and I told them that I had wanted to say thank you but I didn’t want to get into a mess or overstep my station. They said that it didn’t come from them, and it would have come from Stratasys?!?! I don’t know that this will ever happen again but you could try. I think they (both groups) sold the Durus material without stressing that it needs an intense (and different than Vero) cleaning regime. When we got the new one, I wanted a proper tech to show me how to install it and when he did, he took the old one back! Too bad - we had plans for trying to clean it.

Unfortunately, as soon as it was clearly not working well, it just got worse and worse. I tried like crazy to clean it with alcohol and Print Head Wizard but it just kept getting more and more clogged. I did do the thing where you jack up the power to the piezo-electric gates. They were at their max and just about nothing was coming out. We sold our old Durus material on eBay and are promising ourselves not to buy/ use any more. Vero is not bad stuff. A little more brittle but at least it works!!

Good luck getting your heads clean! Let us all know if you figure out a way around replacing them. -Juliana

plvcpt

34

Hi Juliana,

In case you don’t know :

The brittleness of the Rigur (RGD450) is halfway between the Durus and the Vero white, black, grey and clear but if you use the Vero blue which is cheaper than the other Vero colors for some reason, it’s brittleness is between the Rigur and the other Vero colors while slightly less rigid.

If you tune your UV lamp at the lowest intensity that will not give you a sticky top surface after printing, your parts will also be less brittle than if the intensity is higher.

I hope this will help you…

Thanks for your input, plvcpt. Nice idea. -Juliana

Ok. Here is the UK head cleaning company which recover my objet30 print head.

www.ksprintservice.net

Kevin Spiers is the one you need to talk to.

Thanks.