jasu

1

Hi hubbers,

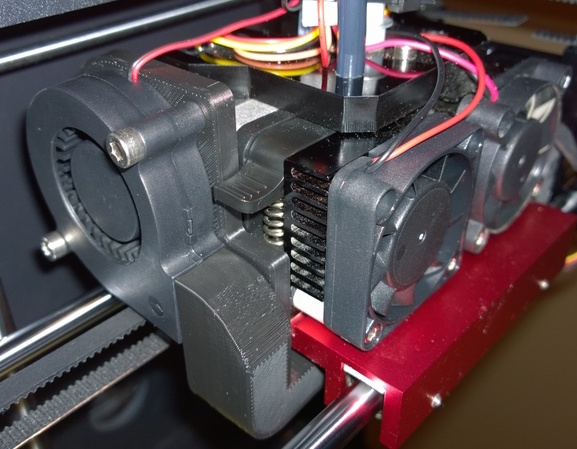

My PLA prints are still mediocre on an unmodified Flashforge Creator Pro. Since I saw recommendations for an active cooling system (go to time 2:38), I had a look around for designs. This is what I found to date:

On MMF from Flashforge a front fan modification with a 1 part fan duct.

Also on MMF, a design by Mark Ledwold. As above a front fan but with 2 parts only one of which seems to be on MMF (see comments).

On Thingiverse, I found this model by Markwal which keeps the fan on the side and probably cools filament coming out of the closer head more than the farther one. It’s a 2 part design.

How did you modify your Flashforge Creator Pro?

Which design did you choose and why?

Any tips for the mounting?

All the best

PS: These are related threads.

2 Likes

lkauf

2

I printed and installed one similar to this. It works great! I did that once and never looked back.

RXnCo

3

Hi,

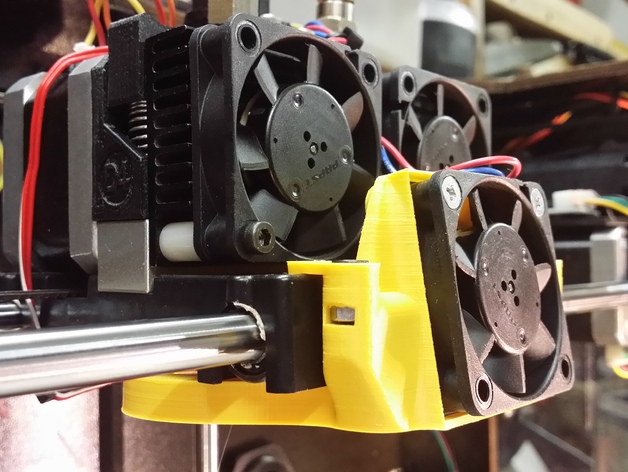

I have a Flashforge Creator X and I’m using this design “Active Cooling Fan Duct” from thruit00 on thingiverse and it works very very well !!!

Regards

3 Likes

KuL3D

4

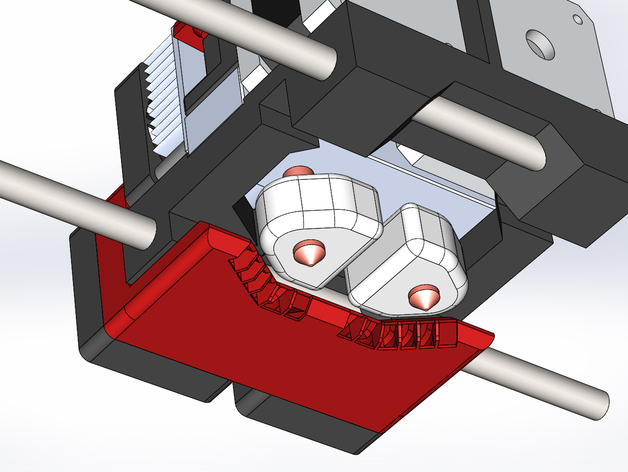

I’ve been using this: Makerbot Replicator 2x Filament Fan Duct w/Magnets!! by pwnate - Thingiverse

But I like the use of the squirrel cage fan…I might switch over.

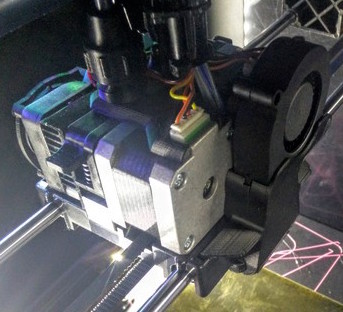

I would suggest the one I made for myself, which is a remix of a remix of the rear cooling duct.

I consider it vastly superior to front fan designs as it takes a lot less space, it’s not as close to the extruders (no risk of melting), and the air flow is better.

2 Likes

jasonk

6

I’m also running this one. Works like a champ! I just wired it to a transformer and plug it in when I want to use it. There is a way to wire it into the FFCP, but this way was just easier.

jasonk

8

Yeah, just moved here to the “homeland”. Designed and printed a set of coasters for my neighbors and they LOVED them. Easy to do with the FFCP.

Right on. I miss AA. I’ve got a lot of experience with my form1+ but am just diving into the Flashforge, which I bought last week. I’m hoping to one day understand purge walls as well as you to get such nice dual extrusion prints!

1 Like

jasonk

10

Hit me up sometime and I can talk you through how I do it. Pretty easy. I use Tinkercad and Makerware. Also, I gave up on Abs. Just use PLA for now and enjoy the nice prints. Hatch box makes nice stuff… Message me your number if you want to talk sometime and I’ll share all my secrets… Lol. Take care!

jasu

11

Hi RiXnCo,

Thanks a lot for your suggestion. This design you are using (left below) doesn’t work with the round turbofan (right below) that comes pre-installed on recent models of FFCP. Did you put a rectangular fan instead to fit into the duct design? I presume one could just disconnect the turbo fan and buy a round one instead. It’s easier at this point though to go for a different design that uses the round turbo fan.

1 Like

jasu

12

Ciao Vincenzo,

This design looks great. I agree with you that rear mounting makes more sense. It’s a little squeezed to mount a bed fan in front of the 2 fans that cool the nozzles.

In your description it says, you might crash into the bed support. Did that ever happen to your knowledge with standard, unmodified gcode. That would be dangerous for our machine, since we have multiple users that won’t know about this additional requirement.

jasu

13

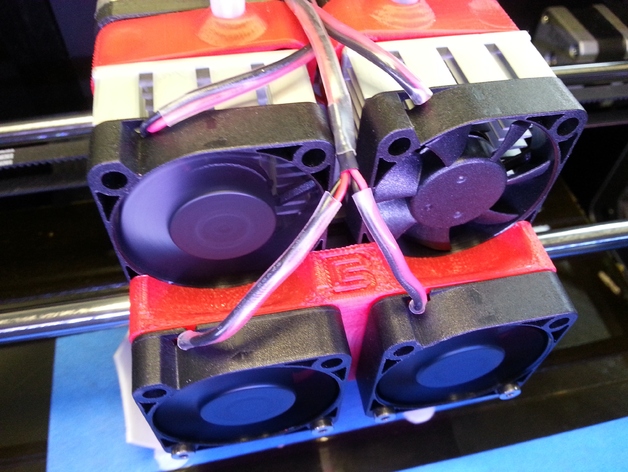

Hi KuL3D,

I initially thought that this was a suction design reusing the 2 main fans and pulling in air to the top (left schematic). Now, that would have been a cool design. But as seen on the right it actually needs 2 additional fans giving us a total of 4 on the FFCP which seems a bit cumbersome. Thanks for the suggestion, though.

jasu

14

Hi lkauf,

A front fan duct for a rectangular not the round turbo fan. I presume your Flashforge didn’t come with the turbo, didn’t it? Seems like a waste not to use a duct design that utilizes the turbo fan if you have one installed already. The rear and font design will probably produces better airflow than the factory sideways duct.

jasu

15

I did a test run with the factory sideways duct and the difference is stunning. This will probably be my most important upgrade.

RXnCo

16

Hi Jasu,

I’ve a 2 years old FFCX and it did not come with any cooling fan system. So I googled and made up one from scratch following tutos and advices. This was a great improvement !!!

So I googled and made up one from scratch following tutos and advices. This was a great improvement !!!

In your case, you could very certainly change the radial fan for an axial one and use the design I’ve pointed out.

Good luck in your quest

And let us know what you end up with. (Who knows I might buy a new FFCP in a near future)

I created a duct that connects the turbo fan to the active cooling duct design here http://www.thingiverse.com/thing:537918.

Works very well.

FanDuctFinal~ 5.stl (108 KB)

It does if you use the duct I made.

FanDuctFinal~ 5_0.stl (108 KB)

1 Like

jasu

19

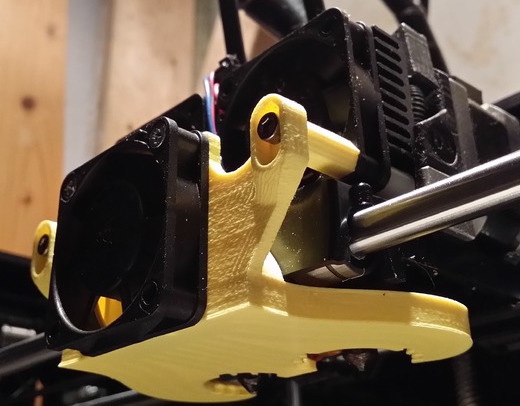

Printed this backside fan and have been using it for a few prints now. Tricky to print because the thin air tunnel needs internal support that is difficult to remove. Very easy to mount. Loosen the bottom screws, slide it in, click in the fan, and finished. No additional screw needed. I have also not experienced any collisions.

Well done. My favorite design off all the ones that I found an listed here.

jasu

20

Hi Chris, thanks for that. Didn’t spot it.