Hello Afiniacs!

I have a H480 with some minor mods.

I get GREAT results with Afinia ABS, Zortrax ABS, Afinia PLA and Polymakr PLA.

I get GREAT results with Octave ABS using the temp mod switch from Octave.

Now the bad:

I can not print with Colorfabb PLA, i bought the BlueGray that i think is a fantastic color, but it will not print for more that 12-15 minutes. I am working on more “invasive” mods to cool down the extruder motor and increase pressure/grip on the filament.

Are there any other filaments that work well with this machine, are there any no-brainer mods that allow Colorfabb filament to work?

Please comment.

4 Likes

The @ColorFabb should be able to give some support here

Alp

3

Hi Krosnyak,

Are you getting a nozzle clog? What is the symptom you’re seeing with the ColorFabb PLA?

Alp

Extruder gear carves into the filament and stops feeding. Maybe because the filament gets too hot and softens or because it’s too thin, I measured and it is well under 1.7mm with bad roundness. I read all over the Internet that colorfabb pla likes hotter temps and has very good dimensional consistency but it is not working for me…

Hi Krosnyak,

What temperature are you trying to print at? On the Makerbot Replicator 195 - 210C, 0.2mm layerheight at 70-80 mm/s works really well.

If you feel the spool is out of specification at many points on the filament please get in touch via support@colorfabb.com so get resolve your troubles.

best regards,

Gijs, team colorFabb

I did that already, they blamed the printer design…

I just Today I tried a spool of ToyBuilderLabs HIPS in their “cool gray” it printed great with no warping!!! I printed a large part using the machine default ABS settings on PEI surface with no raft.

Alp

8

I have the same problem with PLA. I consistently get stepper motor skipping on PLA. That’s why I stick to ABS.

I’ve made an encosure around my afinia which reduces almost all warping to 0.

Yes! That’s the way to go with ABS.

you should try the Z-ABS form ZORTRAX, Octave is selling it now, it is of the best quality and has beautiful colors.

Alp

10

Ill definitely check that out.

I’m curious to hear what you use on your print bed. Masking tape or liquid abs?

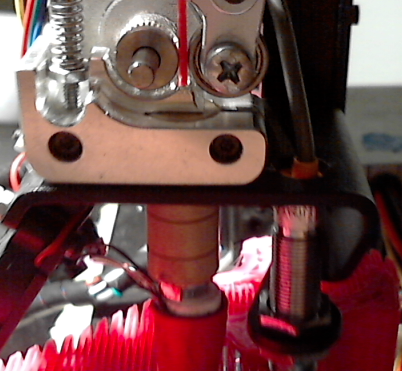

PEI, you find it at Amazon 0.1 inch thick, made some ABS clips to slide it in n out of the platform and hold it tight on the front with a paper clip. It comes glossy like glass, I sanded it down with 400 grit to have a smooth but flat finish. Don’t need to squish the material, actually give it enough room to lay down nicely. Let the bed heat well, make sure you are dead level too and go. ABS, PLA and HIPS stick perfectly, when the print is done, remove it, let it cool and flex a bit. That is it parts just pop off the plate. See pic.

Cheers!

Alp

12

Interesting I never hear of Polytherimide. Is this it? http://www.amazon.com/Polyetherimide-Natural-Standard-Tolerance-Thickness/dp/B00CPRDDLY/ref=sr_1_1?ie=UTF8&qid=1422728200&sr=8-1&keywords=pei&pebp=1422728559586&peasin=B0013HKZTA

I’ve been using the TAK printing surface from Afinia and find it a bit too adhesive. Removing models becomes a bit too intensive. I’m curious if you have experience with borosilicate glass. Does this work better? Also following up with HIPS. Just curious why you use HIPS for.

Yes that is the PEI I use, I never used glass, but the biggest benefit over glass would be the no messy abs slurry. I just sand and wipe with alcohol periodically and it shows no signs of wear or loss of performance.

I tried HIPS because I read something in the Internet that it was stronger than ABS but nearly zero warp like PLA, works well up to 260 degrees too.

it works perfect! Try it

I just bought a roll of colorfab. just tighten it until you get a bead of pla, then one or two more turns.

if you overtighten it, the rollers eject the line. problem I had was that the rollers weren’t pinching hard enough.

I have an UP! Mini which is basically an Afinia. I have had great prints using Makergeeks.com ABS filament, as well as eSun (just search on Amazon). I can’t really get any PLA to print reliably other than the Afinia brand, but they are 3x the price of everything else and only come in a very limited range of colors.

Which PolyMakr PLA did you use? PolyPLUS or PolyMAX? Did you have to make any adjustments or just set the printer to PLA?

Thanks!

I have used Polyplus pla with great success. I mean NO fails. I am sure polymax will work great too but it is expensive.

i have a Octave temp mod for generic ABS.

But pla is simple, just set the software to pla and use ONLY Afinia or Polymaker pla.

btw, polywood pla is awesome!

cheers!

Awesome! Thanks! I want to print with PLA but paying $40 for 500 grams seems a little outrageous, plus they seem to have a very limited color palate. Appreciate the help!