Surface finishes

Aluminum anodizing services

We offer anodizing type II and III, which are ideal surface finishes for aluminum parts. Anodizing strengthens aluminum parts and is available in several colors, depending on the type. All types of anodizing will increase the lead time and cost per part.

Anodizing type II

| Surface preparation | Colors | Glossiness | Cosmetic availability | Thickness** | Visual appearance |

|---|---|---|---|---|---|

| As machined (Ra 3.2μm / Ra 126μin) | Clear, Black, Red, Blue, Orange, Gold | Glossy (Equal or above 10 GU) | No | for clear: minimum average thickness 10μm, minimum local thickness 8μm;black and color: minimum average thickness 15μm, minimum local thickness 12μm | Parts are anodized directly after machining. Machining marks will be visible. |

| Bead blasted | Clear, Black, Red, Blue, Orange, Gold | Matte (2-10 GU) | Cosmetic on request | Same as above | Grainy texture, matte finish |

| Bead blasted | Clear, Black, Red, Blue, Orange, Gold | Glossy (Equal or above 5 GU) | Cosmetic on request | Same as above | Grainy texture, glossy finish |

| Brushing(Ra 1.2μm / Ra 47μin) | Clear, Black, Red, Blue, Orange, Gold | Glossy (Equal or above 10 GU) | Cosmetic on request | Same as above | Parts are manually brushed to reduce marks, then anodized. Brushing lines will be visible.\ |

Anodizing type III

| Surface preparation | Colors | Cosmetic availability | Thickness | Visual appearance |

|---|---|---|---|---|

| As machined (Ra 3.2μm / Ra 126μin) | Black, Natural (thicker layers will appear darker) | No | 35 to 50μm(0.0013” to 0.0019”) | Parts are anodized directly after machining. Machining marks will be visible. |

| Bead blasted (Glass beads #120) | Black, Natural (thicker layers will appear darker) | Cosmetic on request | 35 to 50μm(0.0013” to 0.0019”) | Can be slightly visible if parts are “Not Cosmetic” Completely removed if parts are “Cosmetic” |

* We supply a range of standard colors (see color options). Minor color variations can occur naturally during the anodizing process. Exact shade matching between orders is not guaranteed. For best results, discuss color requirements with your account manager or networksales@protolabs.com.

**As a standard, our anodizing thickness will follow ISO 7599: ISO class AA10 (for clear) and ISO class AA15. If your parts require different standards, please contact networksales@protolabs.com

Color options for aluminum anodizing type II

Color anodizing can have some variation in color due to standard alloy tolerance variations. Check the color scheme below to see the color range.

Color options for aluminum anodizing type III

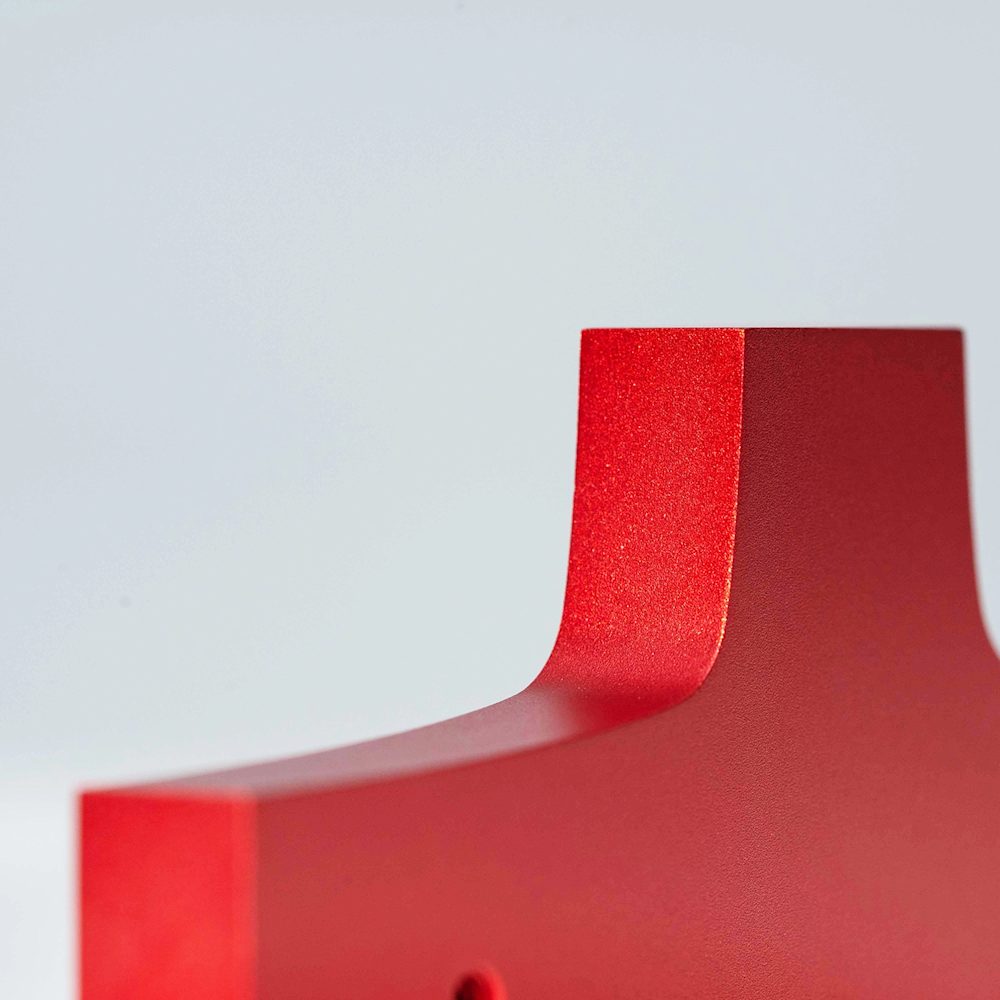

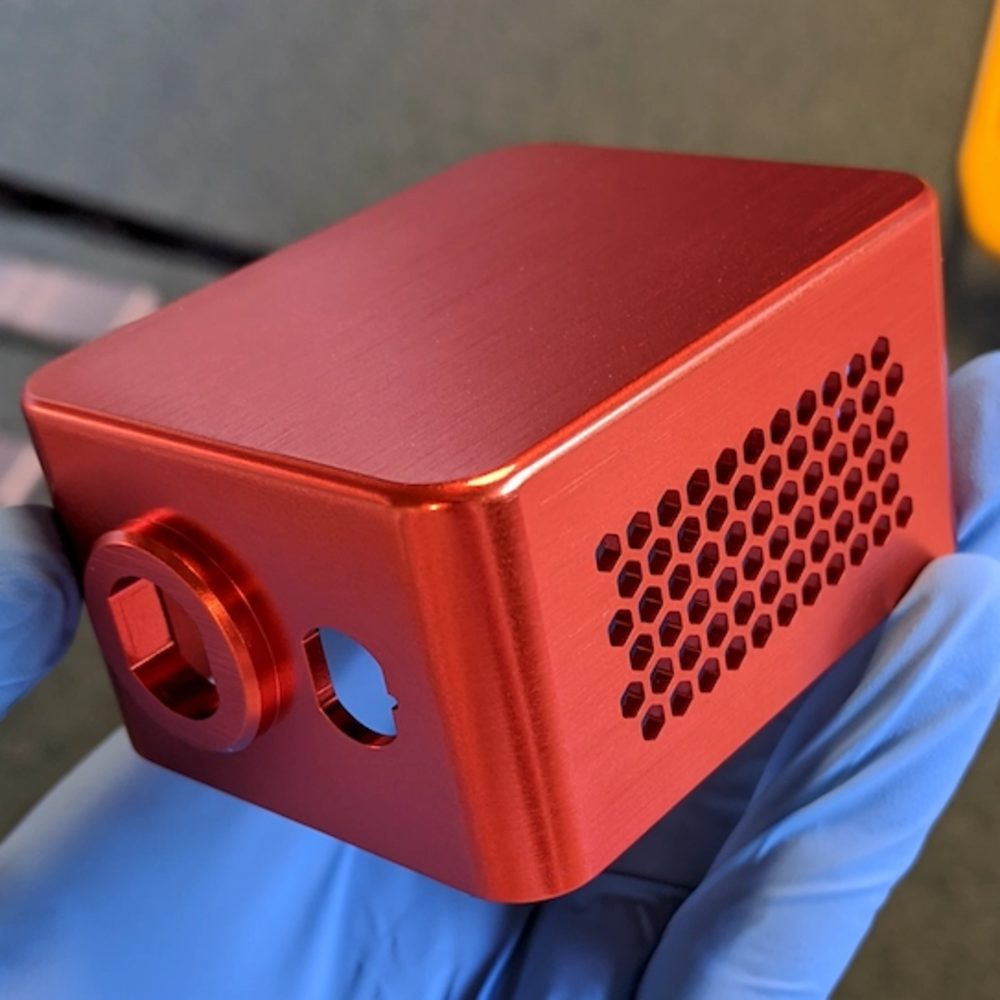

Example of an anodized part

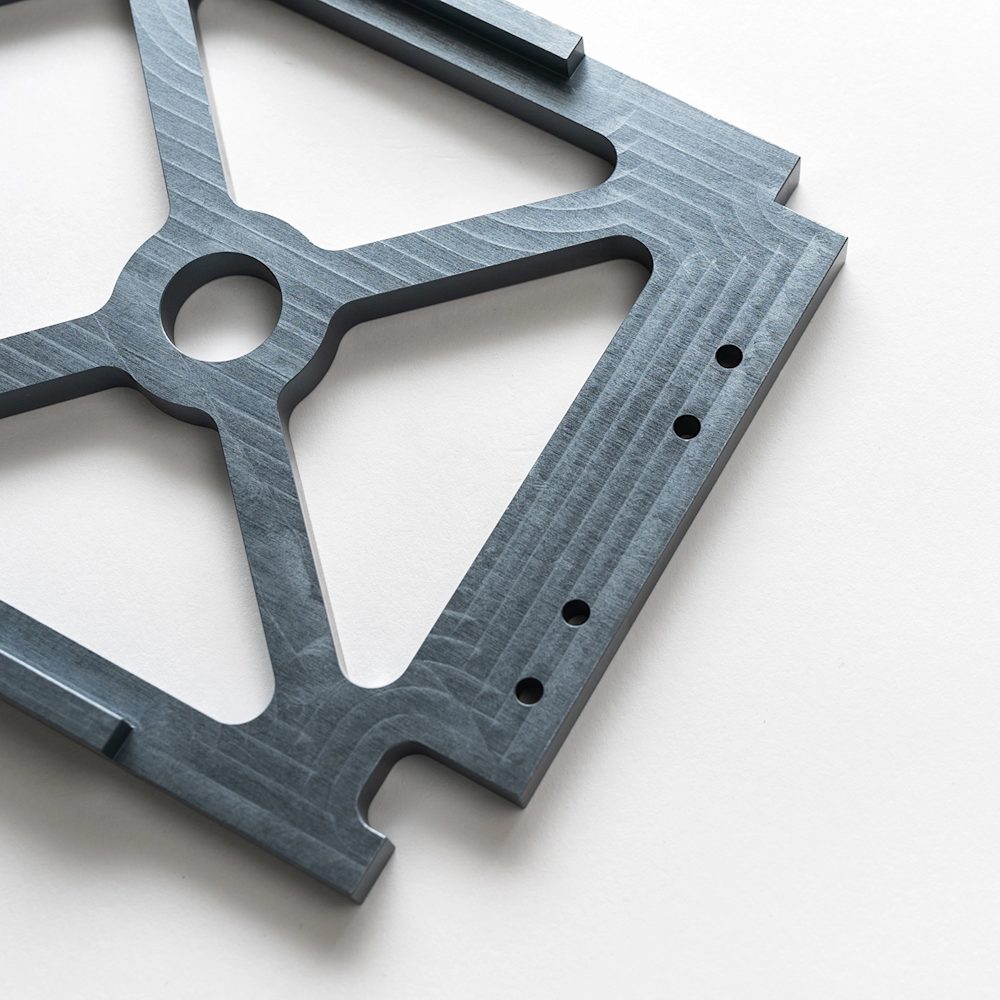

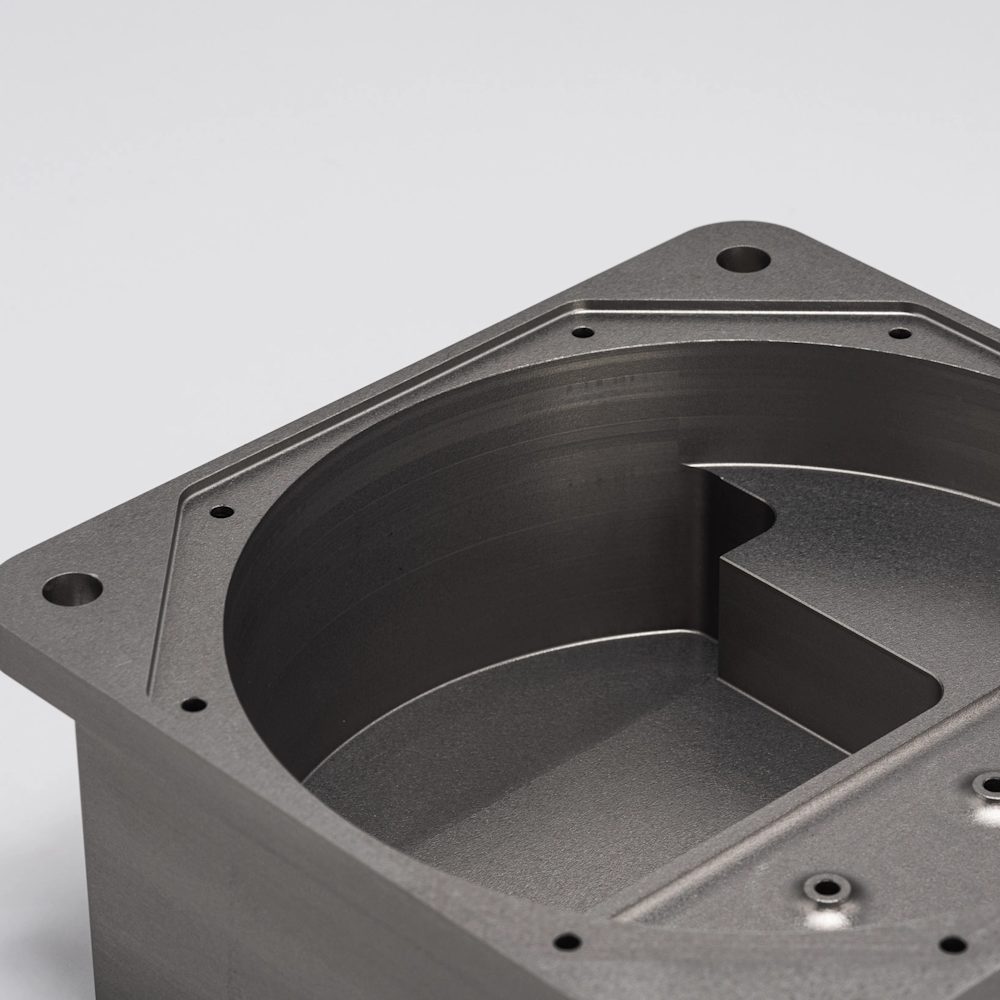

Gallery of anodized parts

Design considerations for aluminum anodizing

- Anodizing involves suspending parts via a “jig” or “rack.” This will leave marks on your part where anodizing wasn’t possible. If there are areas on which you can’t accept “jig” marks, please remember to include a technical drawing indicating these areas and follow our cosmetic procedure. Learn more about this on our surface finishing page

- Anodizing insulates your parts, reducing their conductivity.

- Masking is not required by default, as type II anodizing doesn’t raise the thickness of your part significantly. Remember to indicate in your CAD file whether you want specific part areas to be masked or plugged.

- Type III anodizing, however, adds substantial thickness to your part’s surface. We apply masking by default to protect threads and engineering fits. To have these features anodized without masking, please specify this when placing your order.

Our anodizing process

Anodizing is an electrolytic process both for protecting aluminum parts against wear and corrosion and for improving cosmetic appearances. Let’s break down the basic steps for anodizing a part:

-

Connect the part to an anode

-

Submerge the part in acidic electrolyte solution

-

Apply a cathode to a metal electrode in the solution

-

Positive ions react with negative O2 ions and the surface becomes porous

-

This grows a layer of aluminum oxide on the part

-

Use corrosion inhibitors or colored dyes for cosmetic purposes

-

Seal the nanopores

Aluminum anodizing video resources

Put your anodized parts into production today

Get instant quote