The Protolabs Network Standard

Managing our global network of suppliers

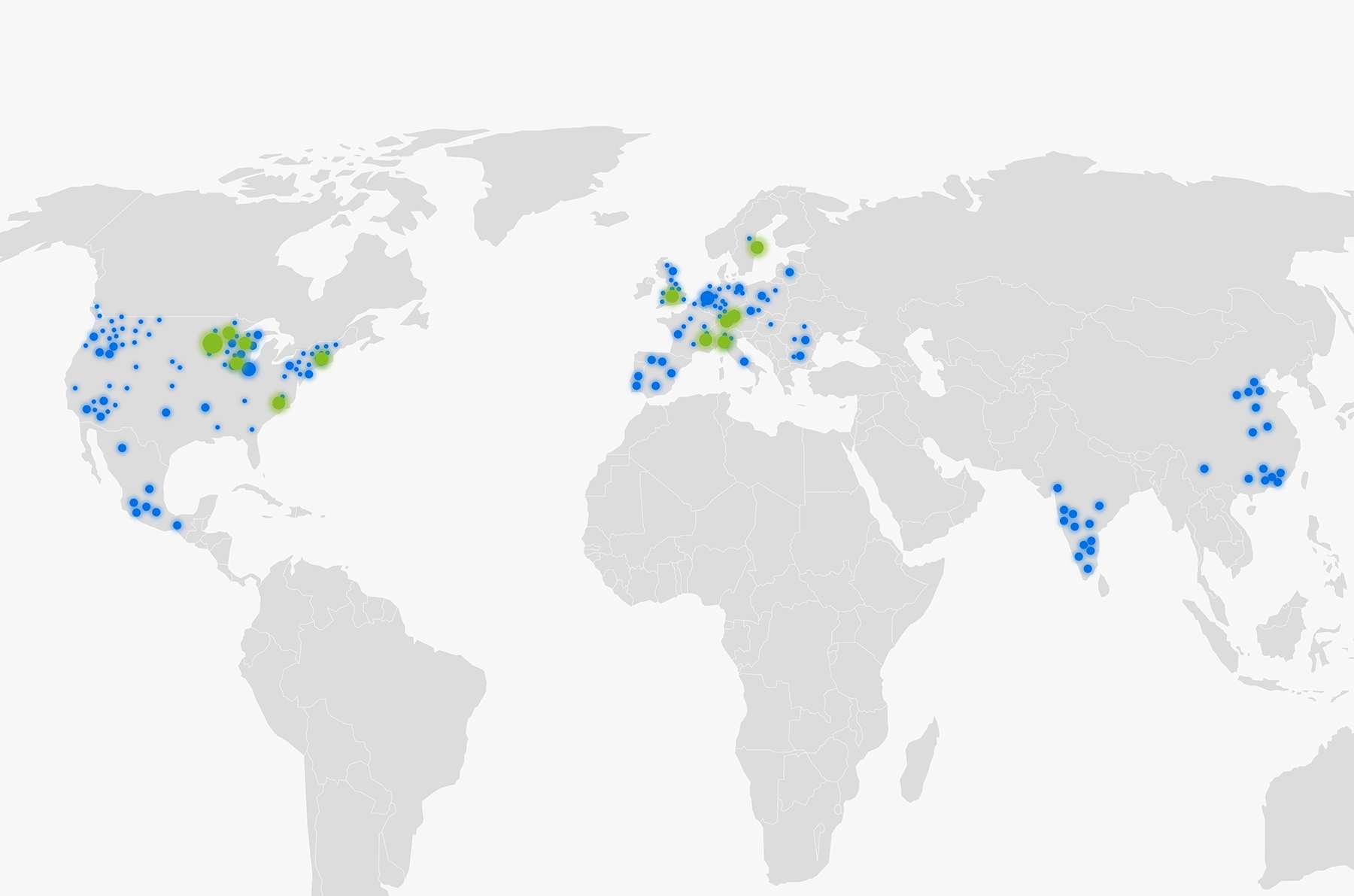

With Protolabs Network, you get access to a network of experienced, specialized manufacturers selected for operational excellence. Our network has the capabilities and capacity to handle any custom parts, giving you complete design freedom and a more resilient manufacturing supply chain.

Maintaining the quality of an entire network

We work with a highly vetted network of more than 250 manufacturing partners and hold each of them to the highest quality standards. To ensure all partners uphold The Protolabs Network Standard, we’ve developed comprehensive systems for selecting and supporting our suppliers. We continually audit our protocols to guarantee we deliver quality parts, every time.

How we select and onboard suppliers

Our network of experienced, specialized suppliers gives us our breadth of capabilities and consistent quality. Protolabs Network has a strict selection and onboarding process for managing and growing this network. For every new supplier we bring onto the network, we use a comprehensive 8-step process:

We approach suppliers we believe meet our standard to gauge interest and assess the match.

We conduct an evaluation to see if the supplier meets Protolabs Network’s qualification criteria. We also provide detailed information on what it’s like to partner with us.

A Protolabs Network auditor assesses quality management performance and environmental/social compliance.

Every supplier has to hold the right registrations and licenses. We do full background checks and sign formal agreements to ensure compliance.

Once suppliers meet our standards, we give them access to the quote-building platform.

To ensure the process runs smoothly from ordering to delivery, we train every MP on the technical standards, logistics and communication requirements behind the platform.

Supply chain managers monitor the first 10 orders of every new supplier. We perform on-site quality control for pre and post-production.

To ensure that our network meets and exceeds industry standards, we audit our MPs on a regular basis and drive continual improvement.

How we audit our suppliers

Manufacturing partners must consistently prove their quality after joining the network. We conduct audits every two years to ensure consistent quality across our network. These audits include quality audits to test capabilities and quality control, and social audits, to confirm environmental and social compliance. We also do frequent spot checks at our major sites.

-

Certifications (ISO/AS)

-

Quality organization

-

Quality policy & objectives

-

Raw material (in & out record dates & Qties)

-

Manufacturing process records

-

Requirement level for suppliers/subcontractors

-

Safe hiring practices and workplace protections

-

Discrimination

-

Fair working hours, wages and remuneration

-

Identification of incoming materials

-

Quality control on incoming materials and records

-

Incoming and outgoing management (FIFO)

-

Identification of batches of ongoing orders

-

Machines & manufacturing equipment

-

Quality controls during production

-

Identification of finishes products/parts

-

Inspection of finished product

-

Health and safety conditions

We are always improving. Here is how we do it.

We aim to keep our line item non-conformance rate below 1% and minimize part issues. If issues do arise, a corrective action plan goes into effect. The MP involved finds the root cause of the issue and improves the process to ensure similar problems do not arise in the future. The Protolabs Network Standards help us ensure your parts are made to spec.

Read more about it on our Quality Assurance page

Some of our vetted manufacturing partners

ISO certifications

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 9001, AS 9100, ISO 13485, ISO 14001 and ISO TS16949. Contact your Account Manager or networksales@protolabs.com to find out more.

Download our ISO 9001 certificate

Ensuring quality locally and globally

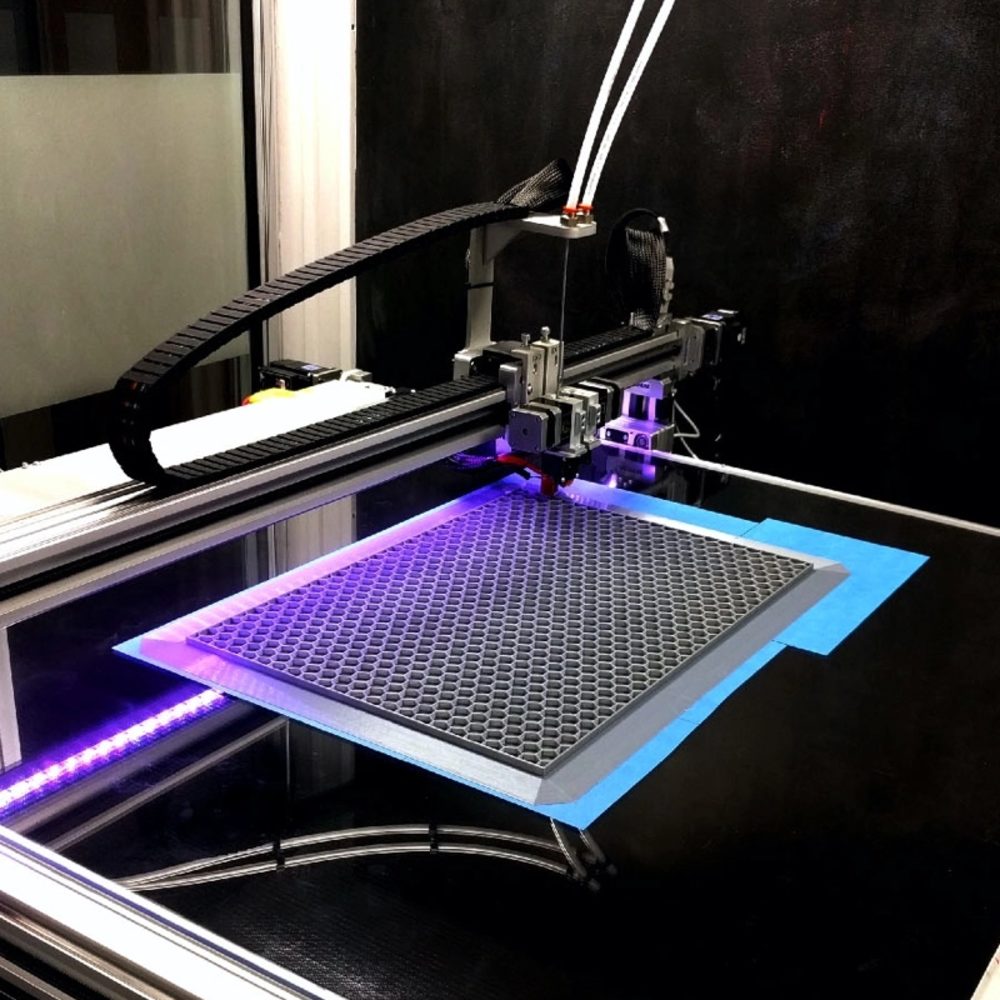

Our platform lets you choose between local and international manufacturing options. Local sourcing is typically faster, but more expensive. All 3D printing and some CNC orders are sourced locally, quality checked by the manufacturer and sent directly to you.

International sourcing is typically more economical. Certain complex CNC machining, injection molding and sheet metal orders can only be sourced globally, and we cover the cost of clearing customs for these orders when you ship to the EU, UK, or US. Depending where they’re manufactured and how complex the parts are, globally sourced orders are first shipped to our cross-docking facilities in Amsterdam or Minnesota for QC inspections, before shipping out to their final destinations.

| Local | Overseas | |

|---|---|---|

| Part quality | Good (The Protolabs Network Standard) | Good (The Protolabs Network Standard) |

| Capabilities | More narrow | Broad range |

| Time to parts in hands | Faster | Slower |

| Pricing | Higher | Lower |

| Shipping time | Shorter (low variance) | Longer (high variance) |

Quality control for parts sourced

Globally

All parts are thoroughly inspected by the manufacturing partner according to our guidelines. Depending on part complexity and the manufacturing location, some orders also undergo a second inspection at our cross-docks in Amsterdam or Minnesota.

Locally

Customers in the US and EU can choose to have their CNC orders sourced through manufacturing partners (MPs) within their custom-clearance borders. Our MPs perform QC inspections, then send the parts directly to you, resulting in fewer logistical hurdles and much faster delivery times. Find out more about local CNC machining.

Customers will be notified if their orders deviate from this standard supply chain flow. For more information, contact the Customer Success Team at networksupport@protolabs.com.

Your parts are in good hands with us. Start a production project today.

Get an instant quote