Most common plastics used in CNC machining

Some plastics rise above the rest in terms of machinability, durability, and suitability for different applications. Here’s a look at the most commonly used plastics in CNC machining:

POM (Delrin/Acetal): Known for its high stiffness, low friction, and excellent dimensional stability, POM is a popular choice for precision parts like gears and bearings. It also has low moisture absorption, so it works well for plumbing and boat parts. But it isn’t a good fit for high-heat environments because it melts at around 165°C.

Nylon: This plastic may be best known for its use in stockings, but it is capable of so much thanks to its strength, flexibility and durability. Nylon’s material properties make it a great choice for bushings, washers, and other components that need to withstand physical stress. However, a common downside with nylon is that it is hygroscopic, so it will absorb moisture from the surrounding air. This can affect its material properties which makes it better for indoor use or in dry environments.

ABS: This thermoplastic is easy to machine and relatively impact resistant. It’s used a lot in the automotive industry for enclosures and prototyping.

PEEK: For high-performance applications, PEEK is the ticket. It offers excellent strength, high chemical resistance and heat resistance with a glass transition temperature (Tg) of approximately 143°C. However, those advantages come with a price tag and PEEK is one of the more expensive plastics to machine, so it's usually only used for critical applications in industries including aerospace and automotive.

PTFE (Teflon): PTFE is known for its low friction and non-stick properties, but it's softer and more prone to deformation under load than PEEK, for example, so it may not be the best option for high-stress components. PTFE has a Tg of approximately 115°C.

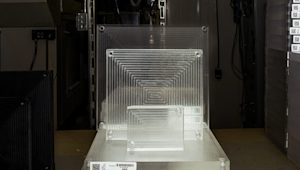

Polycarbonate: Tough and impact-resistant, polycarbonate is often used for transparent components like lenses and safety guards. For optimal results when making transparent parts, we recommend vapor smoothing as a post process.

Polyethylene: This material stands out for its strength-to-weight ratio, chemical resistance, and impact resistance. Polyethylene is often used in consumer products, packaging, and water tanks. It has a relatively low Tg (around 70°C), so it’s not a good choice for high-temperature applications.

PMMA (Acrylic): Often used as a substitute for glass due to its transparency and strength, PMMA is great for display windows, signage, and light diffusers.

PVC: PVC is both tough and chemical resistant. You’ll see it used in pipes, fittings, and industrial parts. It’s affordable and offers good mechanical properties, though its heat resistance is relatively low with a Tg of around 80°C.

Benefits of machining plastics

CNC machining plastics offers many advantages over metals. It is the preferred choice when a project requires a material with the following attributes:

Lighter weight: Plastics are, as you might guess, much lighter than metals, which is crucial for weight-sensitive applications in industries like aerospace and automotive.

Lower cost: Plastic materials and machining costs tend to be lower than metals, especially for prototypes and low-volume production runs.

Faster machining times: Plastics can be machined more quickly than metals, reducing production time.

Less tool wear: Plastics are easier on cutting tools, which leads to less tool wear and more consistent results across production runs.

Drawbacks of machining plastics

Despite the benefits, plastics also present some challenges for CNC machining:

Heat sensitivity: Many plastics can melt, deform, or soften under heat, which can complicate machining processes. Machinists have to dig into their bag of tricks, including staged cooling and slower cutting speeds, to maintain part accuracy.

Dimensional instability: Some plastics, like nylon, absorb moisture, which can cause dimensional changes over time. This can compromise the precision of parts that require tight tolerances.

Limited strength: Compared to metals, plastics generally have lower tensile strength and may not work for high-stress applications, with the exception of high-performance plastics like PEEK.

Surface finish limitations: Achieving a smooth, high-quality CNC surface finish can sometimes be more difficult with plastics, especially those prone to melting.

Geometric challenges: Due to the softness of plastics, some geometries are harder to produce with the same degree of accuracy as other materials, such as deep holes.

Design considerations for machining with plastic

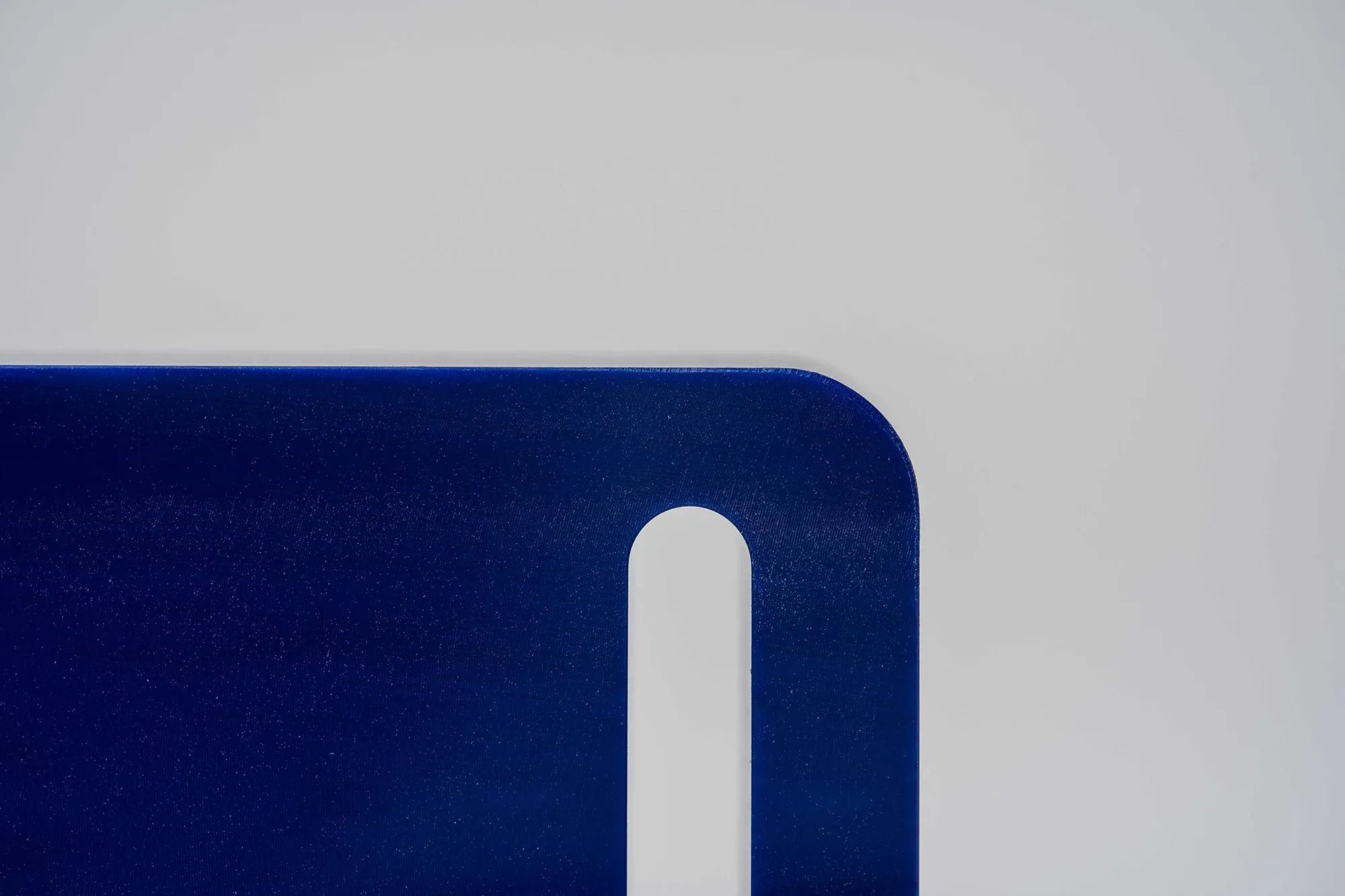

Designing plastic parts for CNC machining is somewhat different from designing metal parts. Plastic materials are less rigid than metals, so wall thickness, radii, and tolerances have to be adjusted accordingly. Engineers have to be wary of thin walls, which can warp during machining, and sharp internal corners, which can create areas of concentrated stress.

Heat buildup can also create complications. Because plastics can soften and deform under heat, it may be necessary to use slower cutting speeds and lighter cuts to prevent the material from warping. Adding cooling methods, such as compressed air or mist coolant, can also help keep temperatures down during machining.

Typical applications of CNC machined plastic parts

Plastics can be ideal for CNC machining precision components across a variety of applications. Here's a look at specific parts and their roles:

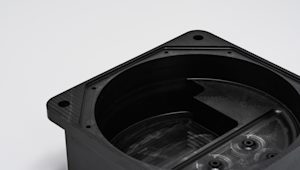

Gears and bearings: Materials like POM (Delrin/Acetal) are perfect for low-friction components including gears and bearings, where smooth motion and dimensional stability are crucial. For example, Inventas used POM to create parts of a cutting-edge bike trailer that required high stiffness and strength-to-weight ratio for components where low friction was essential.

Prosthetics and surgical tools: Recycled polypropylene is often used in prosthetics to create durable, lightweight components. Companies like Circleg use CNC machining to transform recycled polypropylene into affordable, functional prosthetics.

Enclosures and housings: ABS and polycarbonate are commonly used for durable enclosures and housings in consumer electronics and automotive parts. For example, Lektri.co uses polycarbonate to develop electric vehicle charging station casings that are tough enough to withstand inclement outdoor conditions.

Optical lenses and display covers: PMMA (Acrylic) is often used for applications where transparency and durability are key, such as display windows and light diffusers.

Seals and gaskets: PTFE (teflon) is frequently used in seals and gaskets due to its chemical resistance and low friction. Conquering Horizons chose nylon and carbon fiber for complex wheelchair components that needed to be lightweight but strong.

Industries using plastic CNC machining for parts

Many industries rely heavily on CNC-machined plastic components, including:

-

Aerospace: The industry values lightweight materials like PEEK and polycarbonate for high-performance parts.

-

Medical: PEEK and PTFE are often used in surgical instruments, prosthetics, and implants due to their biocompatibility.

-

Automotive: Nylon, ABS, and POM are frequently used in interior and under-the-hood components.

-

Electronics: ABS and polycarbonate are versatile, combining protective properties with a customer-ready finish, so they are used for all sorts of consumer electronics, including smartphone cases and screens, laptop covers, camera housings and more.

-

Robotics: Delrin (POM) is commonly CNC machined to create gears or sliding components for robotic systems.

CNC plastic selection guide

Selecting the right plastic for your CNC machining project depends on several factors:

-

Temperature resistance: For high-temperature environments, materials like PEEK and PTFE should be considered, while lower heat applications might be better suited for ABS or polycarbonate.

-

Chemical resistance: Plastics like PTFE and PVC are ideal for environments with high chemical exposure.

-

Mechanical strength: If your part needs to withstand significant physical stress, PEEK or polycarbonate might be your best bet. For lower-stress applications, nylon and ABS are more cost-effective options.

-

Moisture exposure: POM is a great choice for applications exposed to moisture, while nylon might not be ideal due to its moisture absorption properties.

CNC plastics comparison chart

| Material | Moisture absorption (%) | Glass transition temperature (°C) | Tensile strength (MPa) | Chemical resistance | Wear resistance | Cost ($ per kg) |

|---|---|---|---|---|---|---|

| POM (Delrin) | Low (0.2%) | -10 | 70 | Good | High | 2.5 |

| Nylon | Moderate (up to 7%) | 47 | 85 | Good | Moderate | 3.5 |

| ABS | Low (0.3%) | 105 | 40 | Fair | Moderate | 1.8 |

| PEEK | Very Low (0.1%) | 140 | 90 | Excellent | High | 45 |

| PTFE (Teflon) | Very Low (0.01%) | 126 | 30 | Excellent | High | 30 |

| Polycarbonate | Low (0.15%) | 145 | 70 | Fair | Moderate | 3 |

| Polyethylene | Very Low (0.01%) | between -100 and -130 | 30 | Excellent | High | 1.5 |

| PMMA (Acrylic) | Low (0.3%) | 90 | 70 | Fair | Moderate | 2.8 |

| PVC | Low (0.04%) | 80 | 55 | Excellent | Moderate | 1.2 |

Where to learn more about selecting materials

Not sure which material is the best choice for your next project? Download this free PDF comparison of CNC machining materials or check out all the materials on offer at Protolabs Network.

Get a quote

Ready to get started? Upload your part now for a free, instant quote.

Frequently asked questions

Can all plastics be CNC machined?

No, not all plastics are ideal for CNC machining. While many rigid plastics like POM, ABS, and PEEK perform well, softer or more flexible materials, such as silicone or rubber, tend to deform or melt during the process, making them unsuitable.

What are the best plastics for CNC machining?

Some of the best plastics for CNC machining include POM, ABS, Nylon, PEEK, and polycarbonate. These materials offer a good balance of machinability, strength, and heat resistance.

Why is moisture absorption important for CNC machined plastics?

What is the biggest challenge when CNC machining plastics?

Heat is one of the biggest challenges. Plastics can soften or melt if not machined carefully. This is why materials like LDPE, which has a low melting point, may not machine well, as they can gum up or deform during the process.

Are CNC machined plastic parts durable?

Yes, CNC machined plastic parts can be very durable, especially when using materials like PEEK or polycarbonate, which offer high strength and wear resistance. The durability depends on the application and material choice.