Properties of titanium

Titanium is corrosion resistant and has a high strength-to-weight ratio. Its density is approximately 4.5 g/cm³, so it is denser than aluminum but stronger. This allows engineers to use less titanium than aluminum while achieving the same structural integrity. Titanium is also biocompatible, making it ideal for medical implants. Another bonus: it can withstand high temperatures, which has many applications in theaerospace manufacturing industry.

Uses and applications of titanium

Thanks to its many benefits, titanium is used in a range of specialized industries:

-

Aerospace: Because it is both strong and lightweight, titanium is extensively used to manufacture aviation and aerospace components.

-

Medical: The metal’s biocompatibility makes it a popular choice for surgical implants such as joint replacements and dental prosthetics. Medical manufacturing relies heavily on titanium for devices that interact with the human body.

-

Automotive: Titanium is used in high-performance vehicles to reduce weight while maintaining strength in parts like exhausts and suspensions.

-

Marine: Titanium’s corrosion resistance makes it a great fit for producing deep-sea exploration equipment and other marine applications.

Titanium: advantages and disadvantages

Titanium has an exceptional strength-to-weight ratio but it can also be high cost and difficult to machine compared to metals like aluminum. Here are some of its greatest strengths and weaknesses.

Advantages

-

Strength-to-weight ratio: Titanium’s high strength means less material is required, so you can keep parts lightweight without compromising on performance.

-

Corrosion resistance: It can withstand extreme environments, including saltwater and chemical exposure, without corroding.

-

Biocompatibility: It is one of a few materials that work for medical applications, because it does not have an adverse reaction with living tissue.

Disadvantages

-

Cost: Titanium is pricier than aluminum, both in terms of raw material and processing, as tools can wear out faster while machining the (generally) harder metal.

-

Machinability: The difficulty of machining and welding titanium increases production time and costs.

Properties of aluminum

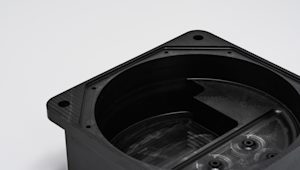

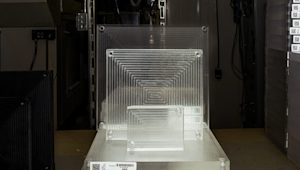

Aluminum has a lot of characteristics that engineers appreciate — it is lightweight, corrosion-resistant, and easy to machine. With a density of about 2.7 g/cm³, it is much lighter than titanium, but not as strong. Aluminum is also highly conductive, so it can be used for electrical applications. Anodizing aluminum builds its corrosion resistance and provides a smooth, matte, uniform finish, which is ideal for applications such as the haptic navigation system Smart-Ship manufactured through Protolabs Network.

Uses and applications of aluminum

Aluminum is widely used in a number of fields where a versatile and cost-efficient metal is required:

-

Automotive: Lightweight aluminum is used in vehicle body panels, engines, and wheels to improve fuel efficiency and cut down on the overall weight.

-

Aerospace: Aluminum is often the metal of choice for aircraft frames, fuselage panels, and other aviation and aerospace components.

-

Consumer electronics: Aluminum’s conductivity makes it useful for heat sinks, cables, and other electronics components.

Aluminum: advantages and disadvantages

Aluminum is a highly versatile metal known for being lightweight, corrosion-resistant and easy to machine. However, aluminum is not as strong as other metals like steel, which can affect its use in high-stress environments.

Advantages

-

Lightweight: Aluminum is significantly lighter than titanium, which is key for many manufacturing projects.

-

Cost-effective: Aluminum is more affordable than titanium, both in terms of raw material and ease of machining.

-

Thermal Conductivity: While it isn’t as resistant to heat as titanium, it has better thermal conductivity, which is useful in cookware, cooling plates, heat exchangers and a wide range of other automotive and electronic applications.

Disadvantages

-

Lower strength: Aluminum is weaker than titanium, which may limit its use in high-stress applications.

-

Fatigue resistance: Over time, aluminum tends to degrade faster than titanium in parts that are subject to intense use and/or bear high-loads.

Titanium and aluminum material comparison

| Property | Titanium | Aluminum |

|---|---|---|

| Density | ~4.5 g/cm³ | ~2.7 g/cm³ |

| Tensile Strength | 434 MPa - 1400 MPa (varies by alloy) | 90 MPa - 570 MPa (varies by alloy) |

| Corrosion Resistance | Excellent (even in marine environments) | Good (can be enhanced by anodization) |

| Melting point | 1795°C / 3263°F | 659°C / 1218°F |

| Electrical Conductivity | 1700 - 2200 MPa | 9030 MPa |

| Izod impact (notched) | Low | High (great for electrical uses) |

| Machinability | Difficult | Easy |

| Cost | One of most expensive | One of least expensive |

| Recyclability | High | High |

| Common Applications | Aerospace, medical, marine | Automotive, aerospace, electronics |

When to use titanium and aluminum in manufacturing

Whether to use titanium or aluminum depends largely on the exact requirements of your project.

-

Use titanium when you need strength, durability, and resistance to extreme environments. For example, inaerospace manufacturing and medical implants, where superior strength and corrosion resistance outweigh the higher cost and machining challenges.

-

Use aluminum when weight, cost-efficiency, and ease of manufacturing are the top priorities. Aluminum is often the better choice in automotive manufacturing, electronics, and general manufacturing where cost-efficiency may be more important than strength.

In some cases, combining both metals offers the best solution. For example, hybrid manufacturing can use titanium for high-stress components while opting for aluminum in less critical parts, to cut down on weight and cost.

Alternative material options

If titanium and aluminum don’t fully meet your manufacturing needs, there are plenty of CNC machining materials to choose from, including:

-

Stainless Steel: It has high strength and corrosion-resistance, but it is much heavier than either titanium or aluminum.

-

Mild Steel: This is a cost-effective material with good strength, but it is heavier and less resistant to corrosion than stainless steel or aluminum.

-

Copper: Known for its excellent conductivity and corrosion resistance, copper is heavier than aluminum or titanium, but not as strong, making it more suitable for electrical applications rather than structural ones.

Order aluminum and titanium parts

Get an instant quote for high-performance custom parts made from aluminum or titanium.

You can explore even more metals for CNC machining on our website or download our CNC materials comparison poster to find the best fit for your project.

Where to learn more about materials

In manufacturing, material selection lays the foundation for performance, cost-efficiency, and durability. Protolabs Network offers a solid selection of more than 80 metals and plastics to shape your manufacturing processes. Check out all the materials available on Protolabs Network.

Frequently asked questions

Is titanium stronger than aluminum?

Yes, titanium is stronger, but its strength comes with a trade-off in weight and cost.

Which metal is better for heat resistance?

Titanium has better heat resistance than aluminum, making it the better pick for high-temperature applications.

Why is aluminum more commonly used than titanium?

Aluminum is more affordable and easier to machine, so it is the more popular choice for large-scale manufacturing, including automotive and electronics manufacturing.

Can titanium and aluminum be used together in manufacturing?

Yes, titanium and aluminum can be used together in hybrid manufacturing, but manufacturers have to take measures to prevent galvanic corrosion when the two metals are in contact.

How does fatigue resistance differ between titanium and aluminum?

Titanium generally has better fatigue resistance than aluminum, especially in high-stress environments where aluminum is more prone to fatigue failure.

Which costs more, aluminum or titanium?

Titanium is more expensive than aluminum, both in terms of raw material and machining costs. But titanium's strength and durability could make it a better value when it comes to long-term savings in high-stress or corrosive environments where it requires less maintenance.