What is chemical resistance?

A material's chemical resistance refers to its ability to withstand exposure to harsh chemicals or solvents. Chemically resistant materials don’t typically require surface treatments or post-processing to achieve their properties as the polymers themselves exhibit chemical resistance.

Why chemical resistance is important

Chemical-resistant parts have long been important in manufacturing and packaging. They’re also one of the major advantages that plastic has over metal. In the absence of chemical resistance, parts may dissolve, become misshapen, or otherwise weaken when introduced to chemicals. This will result in parts or tools that are potentially unusable or unsafe, costing organizations time and money to replace.

How chemical resistance works

Take a look at the industries in which chemical-resistant parts are often used, commonly used chemical-resistant materials, and a few tips on using them.

What industries use chemical-resistant parts?

Chemical-resistant parts are used in a wide variety of industries for a wide variety of applications. Essentially any part that comes into contact with a potentially harsh chemical (whether it’s a solid, liquid, or gas) will need to show at least some chemical resistance. The automotive industry, for example, relies on chemically resistant parts in production plants, where oil, lubricants, and other chemicals are often present.

What are commonly used chemical-resistant materials?

These materials exhibit excellent chemical resistance along with other properties.

-

PP –semi-rigid, translucent, heat-resistant

-

PVDF – abrasion-resistant, UV-resistant, thermally stable

-

Nylon –strong, elastic, resilient, moisture-resistant

-

PA –wear-resistant, thermally stable, strong, hard

The following materials exhibit good chemical resistance along with other properties.

-

PC – strong, stiff, hard, tough

-

TPU – ductile, abrasion-resistant, transparent, elastic

-

PETG –hard, impact-resistant, ductile, transparent

-

ABS –low melting point, impact-resistant, high tensile strength

What are things to note when using chemical-resistant parts?

Considerations for using or creating chemical-resistant parts:

-

Degrees of chemical resistance. A part can be resistant, partially resistant, or non-resistant to chemicals. If partially chemical-resistant, a part or tool may be able to withstand chemicals for short periods of time but will deteriorate if exposed for longer durations.

-

External factors. Temperature, UV exposure, moisture levels, and other environmental forces will have an effect on your part, no matter its degree of chemical resistance. Keep this in mind when selecting the right material for the job at hand.

Designing parts with chemical-resistant materials

Learn about the factors that influence a material’s chemical resistance, applications for chemical-resistant parts, and more.

What are the main factors that influence a material’s chemical resistance?

A material’s chemical resistance is influenced by:

-

Surface area of exposure. The greater the exposure of a part’s surface, the faster and more extensively it will degrade over time.

-

Temperature. Typically, the higher the temperature to which a chemical-resistant material is exposed, the faster it degrades.

-

Chemical strength. The higher the chemical concentration, the harder a material has to work to resist it. This will result in faster degradation.

-

Length of exposure. A chemical-resistant part exposed to a chemical for a long period of time will degrade faster than one exposed to the same chemical for a shorter length of time.

-

Mechanical stress. If a chemical-resistant part is put to work in a stressful, hardworking environment, any resulting change at a molecular-level may lower its chemical-resistant properties.

-

Absorption. A material that absorbs moisture will more readily absorb the chemicals to which it is exposed, resulting in its weakening (either by softening or hardening).

Does chemical resistance depend on the application?

The factors listed above all play major roles in the efficacy of a material’s chemical resistance. This means chemical resistance does indeed depend on the application. Before selecting a material, be sure to understand all of its properties.

Best practices for chemical-resistant materials and parts

Follow these tips and note some design limitations for chemically resistant materials.

-

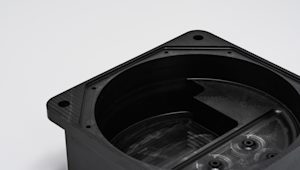

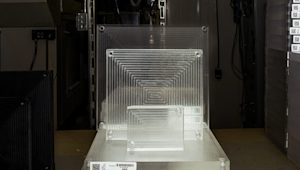

Part strength and design. A part with a complex geometry or a greater surface area exposed to chemicals will degrade faster than a part with a simpler design and a smaller area of exposure. Reinforcing areas of the part where exposure is high can help with its longevity.

-

Choose the right material. Not all materials categorized as chemically resistant are resistant to the same chemicals. This may seem obvious, but it is nevertheless important to consider the type of chemicals or solvents to which your part will be exposed. PVDF, for example, will be unaffected by strong acids and oxidants, while ABS holds up better against alcohols. PP, while resistant to most chemicals, cannot withstand exposure to acetone – to which Nylon is resistant.

Find out more about materials for manufacturing and how to choose the right one for your design.

To produce a part using chemically resistant materials, upload a CAD file for an instant quote and automatic DFM analysis. For further information or recommendations on materials with the right properties for your project, contact networksales@protolabs.com for assistance.

Frequently asked questions

What are the advantages of chemical-resistant parts?

Chemical-resistant parts are able to withstand prolonged exposure to harsh chemicals in industrial environments.

What are the disadvantages of chemical-resistant parts?

Chemical-resistant parts may not exhibit resistance to factors such as high temperatures or UV light.

Which industries use chemically resistant parts?

Chemical-resistant parts are used in all industries, but especially those in which oils, lubricants, solvents, or other chemicals are often present in manufacturing, such as automotive or aerospace.

Are chemical-resistant parts expensive? How do you cut costs on chemical-resistant parts?

Chemical-resistant parts aren’t necessarily expensive, but you can potentially cut costs by selecting the right material for the job at hand, avoiding the need for expensive iterations or replacements. Upload a part to view prices instantly.

How long does it take to produce chemically resistant parts?

The length of time it takes to produce chemical-resistant parts largely depends on the complexity and size of their design. The larger and more complex, the longer the production time.