What is an undercut?

An undercut is a recession (a concave or indented area) or protrusion (an outward extension or raised area) on a part that prevents or complicates ejection from a mold (demolding).

What is the purpose of an undercut?

Generally, designers and manufacturers try to minimize undercuts as much as possible. Some parts, however, need an undercut to function. Let’s take a look at a few of the applications for which an undercut might be necessary.

-

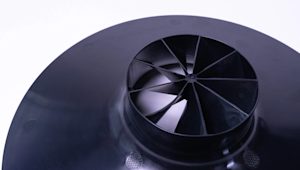

Threaded parts. You can use undercuts to create parts with threads, so you can incorporate screw-on or twist-on fastening mechanisms into them, such as closures, caps, or connectors.

-

Interlocking components. Undercuts enable you to design parts with interlocking features that help them fit together very precisely. A good example here is tool design, where the tool’s handle and tool’s head interlock together to ensure that they are stable and aligned.

-

Sealing mechanisms. If you want to create an effective seal on an injection-molded part – such as those in food packaging or medical devices, which often must be leak-proof or airtight – you’ll probably need to use an undercut.

-

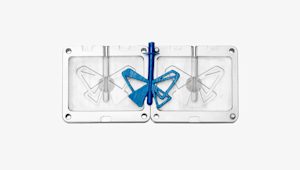

Clips and fasteners. Parts with clips or fasteners, especially in the form of hooks or tabs, often feature undercuts.

-

Molded handles. Handles with ergonomic grips are often designed with undercuts.

How to design undercuts for injection molding

When creating a part that you know will need an undercut, consider adding one or more of the following features to its design. They allow for additional movement or clearance for the undercut, helping ensure that your part is not damaged when demolding.

-

Side action cores. Side action cores are inserts that slide in as the mold closes and slide out before it opens. To be effective, however, side action cores must move perpendicularly to the opening direction of the mold, which may pose challenges to a part’s design.

-

Lifters. Designing parts with lifters is another way to successfully use undercuts. Lifters lift or shift certain features of a part during its ejection from a mold. Like side action cores, they must move perpendicularly to the mold’s opening direction.

-

Unscrewing mechanisms. Threaded components that rotate – like a bottle cap on a plastic bottle – can help a part with an undercut be more easily released from a mold.

-

Draft angles. Your parts should have sufficient draft angles to help it be more easily ejected from a mold. A draft angle is a tapered angle that is applied to the vertical walls of an injection-molded part. In general, you will want your part to have one degree of draft per one inch (2.2 cm) of cavity depth.

-

Parting line placement. You can easily deal with an undercut by moving the parting line of the mold so it intersects with the part feature. This solution is suitable for many designs with undercuts on an external surface. Don’t forget to adjust the draft angles accordingly.

-

Cam slides. Integrating cam slides into your part’s design helps it be ejected in a controlled lateral fashion.

-

Bumpoffs. Bumpoffs function like snaps on a shirt. These tend to work very well when integrated into parts with undercuts, however the material you use must be flexible enough to deform over the mold during ejection.

-

Hand-loaded inserts. Hand-loaded inserts are just that – machined components placed into a mold by hand before the part is injection molded. These components prevent plastic from flowing into certain areas of a mold, and are then removed by hand after the injection molding process.

Challenges in undercut design

Below are a few challenges we often see our customers face when designing parts with undercuts for injection molding. We’ve also provided a simple solution to each.

-

Complicated parts. The more complicated a part, the more difficult it will be to design an effective undercut. With this in mind, use DFM techniques to design your parts as simply as possible, especially if you think they will need an undercut.

-

Part rigidity. The more rigid the material you are using, the more difficult it will be to eject it from the mold. While this might not always be possible, think of materials with high degrees of flexibility and elasticity, such as TPE or TPU, when designing parts with undercuts.

-

Part assembly. Parts with undercuts may pose assembly challenges, especially if components need to precisely fit together. Be sure to design your parts with this in mind, using mating features or assembly aids – and conducting fit testing before committing to a full manufacturing run.

Start an injection molding project

Request a free quote to get your design manufactured with injection molding. You’ll receive expert assistance from our knowledgeable project engineers along the way.

To find out more, you can also find a breakdown of the costs involved in injection molding, how to design parts for molds, and tips for avoiding common manufacturing defects.

Frequently asked questions

Why are undercuts challenging?

Parts with undercuts tend to complicate mold design, demolding, and part production because they have more intricate geometries than those without.

Can you use any material for undercuts?

Ideally, flexible and elastic materials like TPE or TPU are suitable for undercuts.

Does part rigidity affect mold ejection?

Yes, more rigid materials pose more challenges during ejection than those with flexible or elastic properties.

What's the impact of tooling complexity for parts with undercuts?

The more complex mold, the more expensive it is to create and maintain. Work together with your manufacturing partner to find the best solution for your part.

Do undercuts affect part assembly?

Intricate undercuts might cause part assembly to be more complicated, so be sure to design with this in mind.