Standards & technical data

What are the essential industry standards for manufacturing and how do they help you design parts for manufacturability? This collection of standards, tables and conversion charts, including drill bit sizes for CNC machines, will help you source parts faster and smarter.

Understanding material stress vs. strain

“Can you handle the pressure?” That’s the question engineers have to ask of every material they consider when they are designing for manufacturability. Stress and strain are fundamentals of material science, helping engineers assess how materials hold up under different forces. Read on to find out how they are measured.

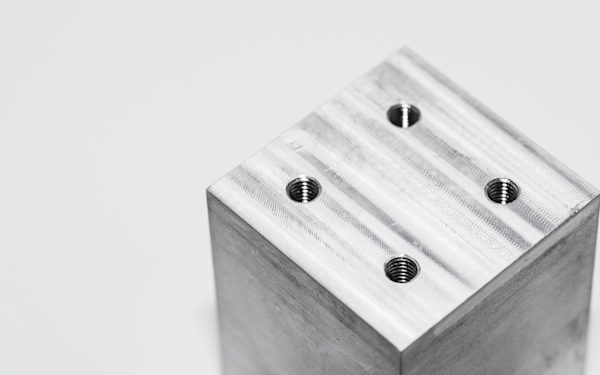

Understanding tapped vs. rolled threads

What are tapped and rolled threads, and what do engineers need to know about them to manufacture high-performance parts? Find out here.

What are countersinking holes and how do you use them?

Countersinking holes are conical holes designed to seat the head of a screw, bolt, or fastener so it sits flush with or just below the surface. This keeps the part’s outer layer smooth, which can improve its appearance, safety and performance. In this guide, we’ll drill into the ins and outs of countersinking, covering methods, applications, pros and cons, and tips for getting it just right.

Standard drill bit sizes for CNC machining

Use these conversion tables of standard drill bit sizes (metric, fractional inch, and wire gauge) common in CNC machining to reduce manufacturing costs from custom tooling.

Standard blank sizes for CNC machining (sheets & rods)

Tables of the standard blank sizes (sheets & rods) commonly used in CNC machining.

What are the different types of threads for manufacturing? Practical tips for engineers

What are the different types of threads for manufacturing? In this article, learn how to correctly design threads to reduce lead times and cost for your next CNC machining production run.