Is nylon a polyamide? This question might seem simple, but the relationship between the two can get a little confusing. For example, you’ll find different names used for materials with identical chemical properties. Don’t worry, we’re here to untangle the amide chains and extrude some clarity. This article will explore the similarities and differences between nylon and polyamides, covering their characteristics, applications, and future trends.

What is nylon?

Nylon is one of the most widely used synthetic polymers in modern manufacturing. It is a specific type of polyamide created through a process known as condensation polymerization, where molecules combine to form long chains and release water as a byproduct. Its structure arms it with several useful properties, such as high tensile strength, elasticity, and resistance to abrasion and chemicals.

Developed by DuPont in the 1930s, nylon became the first commercially successful synthetic fiber. It rose to fame for its use in stockings (ooh la la!) but soon found a place in countless other applications in industries that required strong, lightweight, and durable materials.

Types of nylon

Several different types of nylon are used in manufacturing. Ready for some more chemistry? The numbers in nylon types, such as Nylon 6, Nylon 6/6, and Nylon 12, refer to the number of carbon atoms between the amide groups in the polymer chain, which affects their mechanical and thermal properties.

-

Nylon 6: This is widely used in industrial applications, such as gears and bearings, and is chosen for its mechanical strength, toughness, and wear resistance.

-

Nylon 6/6: This material has high thermal stability and is popular in automotive and aerospace applications when heat resistance is required.

-

Nylon 12: With low moisture absorption and high flexibility, Nylon 12 is ideal for manufacturing tubing and other flexible components.

Characteristics of nylon

Nylon is often a first-draft pick for engineers thanks to its combination of mechanical properties and cost-effectiveness:

-

High strength: Nylon is durable and can bear high loads, so it is a good choice for mechanical components.

-

Wear resistance: Its resistance to abrasion makes nylon ideal for moving parts like gears and pulleys.

-

Chemical resistance: Nylon is also resistant to oils and greases, which makes it perfect for use in machinery.

How nylon is used in manufacturing

Nylon’s versatility makes it a favorite among manufacturing’s heavy-hitting industries, including:

-

Automotive: Nylon is often used in the production of engine components, such as radiator fans, timing belts, and fuel lines, due to its strength and heat resistance.

-

Textiles: Nylon fibers are used in apparel, particularly activewear, outdoor gear and, of course, stockings, because it has durability and elasticity but doesn’t easily break or fray.

-

Consumer goods: You’ll find plenty of nylon at the mall, with products like toothbrushes, kitchen utensils, and zippers all containing this wear-resistance material.

-

Electronics: Nylon is used in electrical connectors and cable ties because it is also a good insulator.

-

Aerospace: Reinforced nylon composites are used in the aerospace industry for parts that require high strength-to-weight ratios — think airframe components.

What are polyamides?

Polyamides are a type of polymer made up of repeating sections connected by amide bonds. Nylon is a specific type of polyamide, but polyamides as a group include both synthetic and naturally occurring materials. One of the most well-known natural polyamides is protein, which is composed of amino acids linked by amide bonds. Polyamides can be classified based on their source (whether synthetic or natural) or their structure (whether they are aliphatic, aromatic, or semi-aromatic). Nylon is classified as a synthetic and an aliphatic polyamide. Aromatic polyamides, like Kevlar and Nomex, have higher thermal and mechanical endurance than aliphatic polyamides like nylon.

Characteristics of polyamides

-

Versatility: Polyamides can be engineered to meet specific performance needs, such as higher chemical or heat resistance.

-

Thermal stability: Many polyamides can withstand extreme temperatures, making them a top choice for high-heat applications.

-

Customizability: Polyamides can be reinforced with glass or carbon fibers to boost their mechanical strength, rigidity, and dimensional stability — but those advantages come with a higher price tag.

How are polyamides used in manufacturing?

Polyamides are used across various industries, in applications where their specific properties—such as flexibility, chemical resistance, or high strength—are essential.

In some cases, a single material will have both a trade name (such Nylon 6) and a scientific name (such a Polyamide 6), but the exact same chemical properties. Just two different names for the same thing. However, there are also polyamides with distinct characteristics that don’t have a nylon counterpart, such as Polyamide 11 (PA11), Polyamide-imide (PAI), PA6T and PA46. Here are a few ways those polyamides are used in manufacturing:

-

Automotive: PA11 is used in automotive fuel lines due to its chemical resistance and flexibility.

-

Aerospace: PAI is used in aerospace applications for components like bearings, seals and electrical insulators, which call for high thermal stability, wear resistance, and chemical resistance.

-

Industrial machinery: Gear housings and many structural components in industrial machinery require PA6T because it can withstand high temperatures and mechanical stress.

-

Medical devices: PA11 is biocompatible, derived from castor oil, and is used in medical tubing, implants and for surgical tools.

-

Packaging: Polyamide films are used regularly in food packaging because of their strength, flexibility, and resistance to moisture and oxygen.

The biggest differences between nylon and polyamides

While nylon is a type of polyamide, not all polyamides are nylon. Here are the key distinctions between nylon and other polyamides:

-

Source and structure: Polyamides are a family of polymers that share a common chemical structure — amide bonds. This can include both synthetic and natural forms, as well as aromatic and semi-aromatic structure. Nylon is a specific type of synthetic polyamide with an aliphatic structure.

-

Applications: Nylon is often used in textiles, automotive, and consumer goods, while other polyamides, particularly PA11 and PA12, are commonly found in packaging, electronics, or medical applications.

-

Moisture absorption: Both nylon and other polyamides absorb moisture, but the degree of absorption and its impact on mechanical properties can vary depending on the specific type of polyamide.

-

Mechanical properties: Nylon is known for its high tensile strength and resistance to wear, but certain polyamides may offer even more flexibility, thermal stability, or chemical resistance. It all just depends on the molecular structure of the material.

Nylon vs. polyamides in manufacturing processes

Nylon and polyamide each offer distinct advantages across the various manufacturing processes, with nylon scoring points for its versatility and cost-effectiveness, while polyamides tip the leaderboard when specialized performance is required, such as improved thermal stability and chemical resistance.

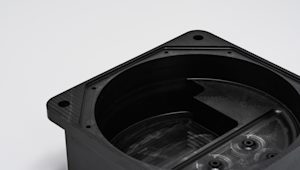

CNC machining: There are many different materials used in CNC machining and nylon and polyamides are both popular choices for prototyping and low-volume production. Thanks to their durability and ability to achieve tight tolerances, Nylon 6/6 and Polyamide 12 are go-tos for CNC-machined gears, bushings, and custom mechanical components.

Injection molding: Injection molding is the most widely used process for producing large volumes of nylon and polyamide parts. Nylon 6/6 and Polyamide 6 are popular IM materials as they can be molded into complex shapes. You’ll see them used often in automotive, aerospace, and consumer applications.

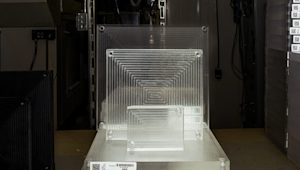

3D printing: Nylon is popping up in 3D printers far and wide, as polyamides gain traction, particularly for Selective Laser Sintering (SLS). Nylon 12 is the hot pick for low moisture absorption, dimensional stability, and for complex geometries. HP has also developed a nylon-based material for its MJF printers, as a growing number of new specialized 3D printing materials shake up the industry.

The future of nylon and polyamides

As the search for stronger, lighter, and more sustainable materials gains momentum, both nylon and polyamides are positioned for major advancements. Innovations in material science may lead to new formulations of nylon and polyamides that improve mechanical properties, environmental impact, and our overall carbon footprints. Here are two areas that we think look particularly promising.

Recycling and sustainability in material science

Recent experimentation with bioinspired materials has had a big impact on manufacturing. Bio-based polyamides, such as the castor-oil derived Nylon 11, offer similar performance to conventional polyamides but with less environmental impact. Both Nylon 6 and Nylon 6/6 can be recycled chemically through depolymerization, which allows for closed-loop recycling. It is early days for this technology, so the process is still evolving.

Smart materials in nylon and polyamides

Smart polyamides, such as shape-memory polymers and conductive polyamides, are being explored for applications in electronics and aerospace. For example, shape-memory materials would snap back to pre-programmed shapes when exposed to heat. Conductive polyamides would incorporate carbon fibers or other conductive materials to make them viable in sensors or smart textiles.

As industries such as automotive, aerospace, and consumer electronics demand stronger, lighter, and more environmentally friendly materials, both nylon and polyamides are answering the call.

The continued development of these materials will drive further innovation and expand the toolbox for engineers as they face the future’s forever unfolding challenges.

Manufacture nylon parts

To order custom parts using nylon, you can instantly view prices and lead times in our online Quote Builder. For more information about manufacturing materials, find out about nylon’s mechanical properties and materials for CNC machining, injection molding and SLS 3D printing.

Frequently asked questions

Are polyamides and nylon the same?

Nylon is a specific type of polyamide, but not all polyamides are nylon. Polyamides include a broader family of polymers with varying characteristics.

Is nylon a polyamide?

Yes, nylon is a synthetic polyamide known for its strength, flexibility, and wear resistance.

Are polyamides breathable?

Certain polyamides, like Nylon 6, can be breathable when used in textiles, but it depends on the application and the way the material is processed.

Is nylon identical to polyester?

No, nylon is a polyamide, while polyester is a different type of synthetic polymer. Nylon generally has higher strength and abrasion resistance compared to polyester.

What is the environmental impact of nylon and polyamides?

Nylon and polyamides, especially bio-based variants like Nylon 11, are becoming more sustainable through innovations in recycling and the development of bio-based alternatives. That said, traditional nylon production does rely on fossil fuels, which has environmental impacts.

How much do nylon and polyamides cost?

Polyamides, including nylon, vary in cost based on the specific grade and reinforcement. Nylon 6 and Nylon 6/6 are usually more affordable than higher-end polyamides like Polyamide 12 or Polyamide-imide (PAI), which perform better in demanding environments. Reinforced polyamides, such as glass-filled Nylon 6/6, offer even higher levels of strength and rigidity, making them more expensive. That additional cost may be required for applications that call for high mechanical performance, such as gears and structural components.