Once you have created an initial prototype, it is time to move on to the functional prototyping phase of the manufacturing process. While initial prototypes allow you to explore and test basic design concepts and ideas, they are often made much more quickly and cheaply than functional prototypes, and are not suitable for giving you an idea as to how your part will function in a real-life situation.

What is a functional prototype?

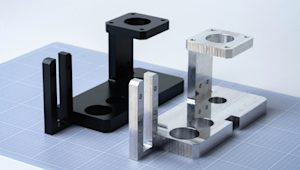

A functional prototype is a working model of a part that is used for testing or validating a concept. They are typically more advanced versions of initial prototypes, created with more durable materials, containing functional components, and ultimately closer to a final product.

Functional prototyping is an essential part of the design process, as it allows engineers and designers to identify and solve functionality issues before committing to a full production run. It also gives them an idea of a part’s manufacturability, helping validate the manufacturing process – as well as the potential return on investment of a particular design.

What materials are used to create functional prototypes?

A successful functional prototype is one that is for all intents and purposes a final part. Some slight tweaks may be required to get it all the way there, but essentially what you see is what you will get once production begins. This means that many – if not all – of a final part’s properties should be present in a functional prototype. The material you use to create your functional prototype, then, is extremely important. The following are three of the most common material categories used to manufacture functional prototypes.

-

Plastics. Used in functional prototyping due to their ease of manufacturing, versatility, and cost-effectiveness. ABS, PLA, and nylon are among the most commonly used plastics for functional prototypes.

-

Metals. Prototypes that require high strength and durability are often made of metal, such as aluminum, steel, or titanium.

-

Composites. Prototypes that must be lightweight – and also require high strength, stiffness, and durability – are often made of composites, such as carbon fiber or glass fiber.

How do you choose a material for functional prototypes?

Here are a few factors you’ll need to consider when selecting a material for functional prototyping.

-

Resistance. If a prototype will be exposed to chemicals or extreme temperatures, the material with which your prototype is manufactured must be able to withstand them.

-

Aesthetic properties. If a prototype’s purpose is to showcase how a finished part will look, you will need to choose a material that possesses those qualities, or consider the time and costs involved in post-processing.

-

Manufacturing process. A prototype’s material should be compatible with the manufacturing process used for prototyping. For example, CNC machining is compatible with a variety of metals and plastics, while 3D printing is better suited to different types of plastics.

-

Cost and availability. Depending on the scale of your project, cost and time may play large roles in creating a functional prototype. Smaller budgets will require low-cost materials, and tight deadlines need faster manufacturing methods.

What manufacturing processes are used to create functional prototypes?

Functional prototypes can technically be created using any manufacturing process. Some, however, are more practical than others. Choosing the right manufacturing process will greatly affect your project’s efficiency, in terms of both cost and time.

The most common manufacturing methods used to create functional prototypes are CNC machining and 3D printing. The right process will predominantly depend on the part’s complexity and required material properties, the quantity of prototypes you need, as well as any budget or time constraints.

-

CNC machining. With CNC machining, you can create functional prototypes in a wide range of materials, including metals, plastics, and composites. The technology’s precision and accuracy make it ideal for creating prototypes with tight tolerances and intricate geometries.

-

3D printing. Fused deposition modeling (FDM) and stereolithography (SLA) are two 3D printing technologies often used to create functional prototypes, especially when plastics are the right choice of material for your project. Both are relatively quick and affordable, and able to create complex geometries and structures.

How do you reduce cost and lead times when manufacturing functional prototypes?

While there are costs associated with functional prototyping, it is unwise to skip the phase entirely. Consider functional prototyping an early investment in batch production, as you will be able to identify design and manufacturability flaws in your part – as well as gain an understanding as to its future return on investment. That said, there are several steps you can take to reduce cost and lead times associated with functional prototyping.

-

Design for manufacturability (DFM). By designing a product with its manufacturability in mind, it's easier to create functional prototypes that accurately reflect the final product and that can be produced efficiently and cost-effectively. Protolabs Network's DFM tool assesses your design for optimal results at the quoting stage.

-

Outsourcing: Outsourcing the manufacturing of functional prototypes to a manufacturing network, such as Protolabs Network, can help reduce lead times and costs by offering instant quotes, optimized orders, and immediate feedback regarding prototype manufacturability.

-

Standardization. Standardizing the design and production processes for functional prototypes can help reduce costs and lead times by eliminating unnecessary variations.

How do you move from functional prototyping to batch production?

After a functional prototype has been created and approved, it is time to take steps toward batch production. However, this doesn't mean you should immediately dive in. A good production process is cautious yet efficient. To achieve this, you can take several steps. Find out more about producing end-use parts.

-

Conduct a pilot run. A pilot run involves producing a small batch of the product to test the manufacturing process and identify any potential issues that may arise.

-

Optimize the production process. Based on the results of the pilot run, the production process can be optimized to improve efficiency and reduce costs.

-

Scale up production. Once the production process has been optimized, batch production can be scaled up to meet demand.

-

Monitor and improve processes. Continuous monitoring and improvement of your production process can help reduce costs and improve efficiency over time.

Ready to get parts produced? Upload your CAD file for an instant quote and DFM analysis.

You can also learn more about the prototyping phase of the manufacturing process, or contact networksales@protolabs.com for personalized advice about your project

Frequently asked questions

What is a functional prototype?

A functional prototype is a physical model of a product that can be tested to validate its form, fit, and function before final production.

Why is functional prototyping important?

Functional prototyping allows you to identify and address potential issues early in the development process, reducing the time and cost associated with product design and production.

What materials are commonly used for functional prototyping?

Common materials used for functional prototyping include plastics, metals, and composites

How is a functional prototype manufactured?

Functional prototypes can be manufactured using a variety of techniques, including 3D printing and CNC machining.

What factors should be considered when designing a functional prototype?

Designers should consider the functional requirements of the part, its size, shape, and complexity, the material properties, and the manufacturing process used to create the part.

How long does it take to manufacture a functional prototype?

The time it takes to manufacture a functional prototype varies depending on the complexity of the part, the chosen manufacturing process and other factors.

Can functional prototypes be used for production?

Functional prototypes can serve as a basis for production, but additional testing and refinement may be necessary before final production.

What are the benefits of functional prototyping?

Functional prototyping provides an indication of the return on investment of your part. You’ll also be able to identify design flaws, and reduce lead times and costs of batch production.

Is functional prototyping expensive?

The cost of functional prototyping varies depending on materials used, part complexity, and manufacturing process, but it is often more cost-effective than moving straight from initial prototyping to batch production.