Whether it’s a prototype, housing for sensitive components, or a mechanical component, parts for electronics must meet stringent quality and performance standards. To ensure they do so, you must take a meticulous approach to their manufacture – one which encompasses materials, design, and production methods. In this article, we’ll take a look at all of the above, so you can make informed decisions about manufacturing parts for electronics.

Types of parts commonly manufactured for electronics

The types of parts you’ll need for electronics will of course depend on the product. However, the following parts are those that we often see our clients manufacture.

-

Plastic casings. Plastic injection molding is frequently used to manufacture sleek and lightweight casings for various electronic devices, providing durability and aesthetic appeal.

-

Metal enclosures. Aluminum and steel enclosures serve as protective shells for electronic devices like industrial control systems, server racks, and scientific instruments, shielding internal components from external elements.

-

Printed Circuit Board (PCB) mounting brackets. These brackets securely hold PCBs in place within electronics like medical devices and industrial sensors, ensuring stability and proper alignment of electronic components.

-

Battery housings. Battery compartments are precision-engineered to accommodate rechargeable and non-rechargeable batteries in various electronic applications, such as medical equipment, remote monitoring devices, and instrumentation, providing convenient power solutions.

-

Hinges and mechanical components. Used in electronics like field equipment, aerospace instrumentation, and industrial machinery, these components ensure reliable movement and functionality of critical parts.

-

Prototypes. Prototypes are often produced with various forms of 3D printing for a wide range of electronic applications, including custom sensors, research equipment, and specialized instrumentation, allowing for quick iterations and testing of new designs.

Manufacturing methods for electronics

Manufacturing methods for parts for electronics encompasses a spectrum of techniques, from injection molding to 3D printing to sheet metal fabrication. The right method for your use case should be chosen based on the final application for your part.

-

Injection molding. Injection molding is a widely used method for producing plastic components such as casings, enclosures, and keypads. Molten plastic is injected into a mold cavity and cooled to form the desired part. It's efficient for high-volume production and offers precise detailing.

-

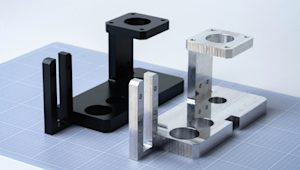

CNC machining. CNC machines precisely remove material from a solid block, creating parts with high tolerances and complex geometries. With CNC machining, you can create precise and intricate metal parts for electronics, such as aluminum enclosures with custom-designed cutouts for circuit boards and connectors.

-

Die-casting. Die-casting is employed to create metal parts with intricate shapes, such as aluminum or zinc alloy enclosures. Molten metal is injected into a mold, cooled, and then removed, resulting in highly detailed and durable components. It is a good choice for producing complex electronic components like heat sinks or lightweight yet durable aluminum alloy casings with intricate designs and fine details, such as those used for smartphones or tablets.

-

Sheet metal fabrication. Our sheet metal fabrication service involves cutting, bending, and assembling thin sheets of metal such as aluminum or steel to create various components like enclosures, brackets, and chassis. This method is especially suitable for parts requiring strength, durability, and electromagnetic shielding, often found in devices like computers, amplifiers, and servers.

-

3D printing. 3D printing allows for the creation of intricate, custom-designed components layer by layer. It’s advantageous for rapid prototyping and low-volume production of parts such as housing, unique connectors, specialized brackets, or prototypes of final products.

Selecting materials for parts for electronics

When selecting a material, you should consider several factors regarding the nature of the electronic your part is meant for. These factors will vary depending on the application, but here are a few important – if not universal – ones.

-

Functionality. Ensure the material meets the functional requirements of the part, such as electrical conductivity, insulation, heat resistance, or mechanical strength.

-

Durability. Consider the material's ability to withstand wear and tear, impacts, and environmental conditions relevant to the device's use.

-

Weight. Choose a material that balances the need for strength with the desire for lightweight components, especially for portable devices.

-

Cost. Material cost can significantly impact production expenses, so balance material performance with budget constraints.

-

Manufacturability. Assess whether the chosen material is compatible with the manufacturing processes needed to produce the part efficiently.

-

Heat dissipation. Determine if the material can dissipate heat effectively, which is crucial for components exposed to heat-generating electronics.

-

Dimensional stability. Choose materials that maintain their shape and dimensions under varying temperature and humidity conditions.

-

Aesthetics. The material's appearance and finish should align with the device's design and user expectations.

The exact material you need will also depend on the part’s intended application. However, we often see our clients use the following to create parts for electronics.

-

Plastics. PC, ABS, and PP are extensively used for 3D printed or injection-molded casings, enclosures, and various internal components due to their lightweight nature, versatility, and ease of molding. Additionally, PC, ABS, and PP offer different characteristics, such as impact resistance, heat resistance, and chemical resistance. Find out more about these and other materials commonly used in injection molding.

-

Aluminum. Aluminum is favored for its lightweight yet sturdy properties. It's commonly used for casings, heat sinks, and structural components in laptops, smartphones, and audio equipment. It offers excellent heat dissipation and a sleek appearance.

-

Steel. Steel, especially stainless steel, is employed for durable and corrosion-resistant components in electronics, including structural elements, fasteners, and hinges.

-

Silicone. Silicone rubber is valued for its flexibility, heat resistance, and electrical insulating properties. It is used in electronics for sealing, shock absorption, and as a protective covering for cables and connectors.

-

Carbon fiber. Carbon fiber composites are employed for their exceptional strength-to-weight ratio and resistance to electromagnetic interference (EMI). They are used in high-end or hard-working electronics for structural reinforcement and EMI shielding.

Surface finishes for parts for electronics

Surface finishes can provide parts with enhanced aesthetics, durability, and functionality. Here are five commonly used surface finishes, with examples of how they could be used in electronics-related applications.

-

Anodizing. Anodized aluminum surfaces with enhanced corrosion resistance and an attractive finish find application in electronics like aerospace components and medical instruments, where durability and appearance are critical.

-

Electroplating. Electroplated coatings like gold or chrome enhance the conductivity and appearance of connectors, switches, and buttons in various electronic systems, including telecommunications equipment and automotive electronics.

-

Painting and powder coating. These finishes provide customized colors and protective layers for plastic and metal components in electronic applications such as industrial control panels and outdoor electronics, ensuring both functionality and aesthetics.

-

Brushed and polished finishes. Stainless steel and aluminum components can be brushed or polished to achieve a premium appearance in electronic devices like high-end audio equipment, laboratory instruments, and precision measurement tools, enhancing their overall appeal.

Design for manufacturability for electronics

Design for manufacturability (DFM) is a critical aspect of creating efficient and cost-effective parts for electronics. Optimizing designs can streamline production processes and improve overall product quality. Our built-in DFM analysis considers these aspects of your part:

-

Simplicity. Minimize complexity to reduce manufacturing errors and costs.

-

Tolerances. Specify tolerances that balance precision with cost-effective manufacturing.

-

Assembly. Design parts that are easy to assemble, reducing labor and time.

-

Standardization. Use standardized components to simplify sourcing and reduce costs.

-

Testability. Incorporate features that ease quality control and testing during production.

Part consolidation. Combine multiple components into single parts where feasible, simplifying assembly and reducing the number of required parts.

Start production on electronics components

Find out more about using Hubs for the consumer electronics industry. Learn more about manufacturing consumer products, and popular topics on our Knowledge Base related to CNC machining, 3D printing and injection molding.

When you’re ready to put electronics parts into production, get an instant quote.

Frequently asked questions

Which materials are commonly used for electronics?

Commonly used materials include plastics, aluminum, and steel, each chosen based on specific functional and aesthetic requirements.

What are some key manufacturing methods for electronics?

Common manufacturing methods for electronics parts include injection molding, CNC machining, die-casting, and 3D printing, offering versatility and precision.

Why is Design for Manufacturability (DFM) important for electronics?

DFM is vital because it optimizes product designs to enhance manufacturability, reduce production costs, and ensure efficient, cost-effective production processes.

How do surface finishes enhance electronics?

Surface finishes, such as anodizing, painting, and electroplating, improve electronics' aesthetics, durability, and functionality, enhancing user appeal and product lifespan.

What factors should I consider when selecting materials for these parts?

When selecting materials for electronics, consider factors like functionality, durability, cost-effectiveness, and compliance with industry standards and regulations.

What are some common challenges in electronics manufacturing?

Common challenges in electronics manufacturing include achieving precision, maintaining high-quality standards, and meeting production deadlines, which require careful planning and execution