Electroless nickel plating is a post-processing technique that deposits a layer of nickel onto the surface of a part. It results in parts with improved corrosion resistance, wear resistance, and hardness. In this article, we’ll explore how electroless nickel plating works, its advantages, applications, commonly used materials, and more.

What is the difference between electroplating and electroless nickel plating?

While electroplating relies on an electrical current to drive the plating process, electroless nickel plating is a chemical reaction. This means it occurs spontaneously if you provide the proper conditions. Let’s take a look at how electroless nickel plating works in the following section.

How does electroless nickel plating work

Electroless nickel plating is the result of a chemical reaction between a reducing agent and nickel salts. Unlike other forms of plating, electroless nickel does not require an electrical charge through the part. The nickel salts used in electroless nickel plating typically contain phosphorous or boron. The type of nickel you will need depends on the desired properties of the final part.

-

Nickel-phosphorous. Offers good corrosion resistance and hardness. Protolabs Network offers nickel-phosphorous nickel plating

-

Nickel-boron. Offers good wear resistance and hardness.

Once you’ve decided on the type of nickel, the electroless nickel plating process looks something like this.

-

Surface preparation. First, the part’s surface is thoroughly cleaned to remove contaminants such as oils, greases, or oxides, to ensure good adhesion of the nickel layer.

-

Activation. The part’s surface is activated using a chemical solution, preparing it to attract and hold the nickel.

-

Immerse part in plating bath. The part is immersed in an electroless nickel plating bath, which contains nickel salts, a reducing agent, stabilizers, and other additives. The reducing agent reacts with the nickel salts, causing the nickel to deposit uniformly onto the part’s surface.

-

Controlled deposition in plating bath. The plating process is typically carried out at controlled temperatures and pH levels, so the final coating has your desired properties. Typically, the longer the plating time, the thicker the coating.

-

Post-processing. Once the plating process is completed, the nickel-plated part can be further post-processed, if desired. Common post-processing treatments for electroless nickel plated parts include heat treatment and sealing. Specific requirements for post-processing your electroless nickel-plated parts with Protolabs Network can be made as a custom request.

What materials can be electroless nickel plated?

You can use electroless nickel plating with number of materials. Here are a few that we see our customers most commonly use.

The materials listed in bold are offered by Protolabs Network. Those in italics are potentially available with plating as custom requests. If a material is neither bolded nor italicized, Protolabs Network does not currently offer it.

-

Steel, including carbon steel and stainless steel

-

Copper and copper alloys, such as brass and bronze

-

Magnesium

-

Certain ceramics

-

Composites

-

Glass

What are the advantages of electroless nickel plating?

Here are a few of the advantages that electroless nickel plating can provide to parts.

-

Uniform coating. Electroless nickel plating provides a uniform coating thickness to parts, even on complex shapes and internal surfaces.

-

Corrosion resistance. Parts that have electroless nickel coatings exhibit excellent corrosion resistance, making them ideal for parts exposed to harsh environments.

-

Wear resistance. The hardness of the nickel-phosphorus or nickel-boron alloys provides excellent wear resistance, increasing the lifespan of the coated parts.

-

Electrical and thermal properties. Coatings achieve with electroless nickel plating can also improve electrical conductivity and offer good thermal stability to parts.

What are the disadvantages of electroless nickel plating?

Electroless nickel plating also has its limitations. Let’s take a look.

-

Limited thickness control. Whereas you can precisely control electroplated coatings by adjusting the electrical current, electroless nickel plating offers a relatively limited control over coating thickness, compared to other forms of plating. You can partially influence thickness by plating time and temperature, but it might be challenging to achieve very precise levels – in terms of micrometers – of it.

-

Porosity. Electroless nickel coatings can be porous, especially when plating on certain materials or in less controlled conditions. This can lead to decreased corrosion resistance, and can also result in parts that are not fit for marine applications, in which they are exposed to prolonged wet or damp conditions.

-

Brittleness under heavy stress. High phosphorus electroless nickel coatings can be brittle under heavy stress, leading to cracking or chipping, especially if it is deposited in thick layers. However, good plating adhesion can help limit this.

Best practices for designing parts for electroless nickel plating

To achieve best results with electroless nickel plating, consider the following design tips.

-

Account for part geometry. Design parts with simple and uniform geometries to facilitate even plating thickness. Additionally, you should avoid sharp corners, crevices, and tight recesses, as they can lead to uneven plating.

-

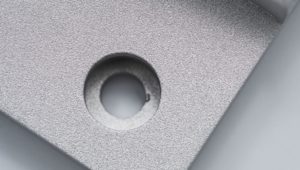

Drainage holes. Include proper drainage holes, slots, or channels to allow plating solutions to flow freely and avoid trapped air pockets. Blind holes may result in lower thickness or poorer adhesion in that area.

-

Surface finish and texture. Use parts with surface finishes that promote good adhesion of the electroless nickel coating. Typically, smooth finishes with Ra (roughness average) of between 2 and 4 micrometers work best. On average, plating will double the roughness of a part. For example, Protolabs Network’s electroless nickel plated parts start out by being smooth machined (Ra 1.6), so that after plating they return to a finish roughly equal to our standard (Ra 3.2).

-

Masking. Be sure to mask areas of your part that should not be plated. You can mask these areas with tape, plugs, or temporary coatings. Protolabs Network masks tapped holes by default – the rest can also be masked as a custom request.

-

Dimensional tolerances. Maintain tight dimensional tolerances, which account for the plating thickness, to ensure the nickel plating does not interfere with assembly or mating parts.

Which industries use electroless nickel plating?

Protolabs Network’s customers that use electroless nickel plating operate in the following industries.

-

Automotive. For corrosion- and wear-resistant engine components, fuel systems, and brake systems.

-

Aerospace. For coating aircraft components to improve their corrosion resistance and dimensional stability.

-

Electronics. To protect connectors, contacts, and other components.

-

Oil and gas. To coat valves, pumps, and other equipment for resistance to harsh chemicals and environments.

Order parts with electroless nickel plating

To get an instant quote for a custom part with electroless nickel plating as a post-process, upload a CAD file for instant pricing and lead times. Contact networksupport@protolabs.com to discuss your requirements.

You can also read more about post-processing and surface finishes, and how to choose the right process for CNC machined parts.

Frequently asked questions

What are typical phosphorus levels in high-phosphorus plating?

High-phosphorous nickel plating contains around 8-13% phosphorus.

Can you selectively apply electroless nickel plating?

You can use masking techniques to achieve more precise plating in specific areas of a part.

Is electroless nickel magnetic?

High phosphorus formulations of electroless nickel plating are usually not magnetic.