Transitioning from a prototype to a full production run is a big step, requiring a great deal of preparation. In this blog, we’ll take a look at the design practices, materials, post-processes, and other factors affecting product scalability that you may need to consider before heading into production.

What is product scalability?

In manufacturing, “scalability” refers to a part’s or product’s ability to be manufactured at increased volumes without sacrificing quality, resulting in disproportionate cost increases, or running into production difficulties.

Improving a part’s scalability involves a multipronged approach that encompasses your part’s design (including materials), the manufacturing processes used to create it, supply chain optimization, and continuous improvement. In several of the following sections, we’ll take a closer look at each aspect of product scalability, but first let’s examine how product scalability differs from Design for Manufacturability (DFM).

How is product scalability different from Design for Manufacturability (DFM)?

Product scalability and DFM might be related, but by no means the same concept. Product scalability focuses on handling increased demand or usage, while DFM optimizes product design for efficient, cost-effective production. As you’ll see below, DFM plays an important role in product scalability.

What are the benefits of product scalability?

Scalable products are, perhaps obviously, beneficial to manufacturers in a variety of ways. Take a look at the following.

-

Cost efficiency. Scalable products often benefit from economies of scale, meaning the cost per unit decreases as the production volume increases. This means your production costs will be lower, simultaneously helping you competitively price your finished product on the market and boosting your profit margins.

-

Flexibility. With products that are scalable, you are more easily able to adapt to changes in demand, ramping up or down production levels as needed without significant disruptions or excess inventory.

-

Streamlined operations. Scalable products are the result of streamlined processes and standardized operations, which themselves often lead to improved efficiency – in terms of reduced lead times and lower inventory costs, for example – throughout production and the supply chain.

What are the challenges involved in creating scalable products?

Conversely, achieving products that are scalable may pose several challenges to your organization. Addressing these challenges requires a combination of technical expertise, strategic planning, and continuous iteration and improvement throughout the product lifecycle.

Production capacity. One of the primary challenges in manufacturing scalability is ensuring that production capacity can meet increasing demand without compromising quality or efficiency.

Supply chain management. As you scale your manufacturing processes, you may need to scale the supply chain along with it. This will help ensure that you consistently and reliability have the materials and components you need to stay operational.

Quality control. To maintain consistent product quality, you’ll need effective quality control processes. Implementing these processes may become challenging as production volumes increase, as they often require continuous monitoring and improvement.

Inventory management. Balancing inventory levels to meet fluctuating demand while minimizing carrying costs and avoiding stockouts or overstock is a significant challenge in manufacturing scalability.

Design and product scalability

The first step in optimizing your product’s scalability is taking steps to optimize its design. Here, you’ll want to focus on the following factors.

-

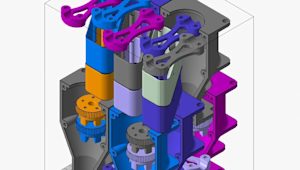

Simplify design. In the design phase, think about how you can reduce your product or part’s complexity. Maybe this means designing it with fewer parts, or with as few assembly steps as possible.

-

Design for Manufacturability (DFM). Optimize your design for ease of manufacturing, collaborating closely with manufacturers to ensure compatibility with their capabilities.

-

Tolerances and fits. Design parts with tolerances that strike a balance between precision and cost. That balance is key. Parts with very tight tolerances can be difficult to manufacture, but cut costs too much and you will risk losing functionality.

-

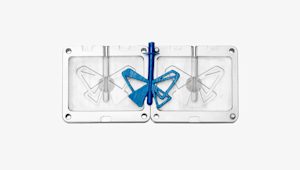

Standardization and modularity. If a feature – like a fastener or a connector – on your part or product can be standardized, standardize it. This will greatly help cut costs and streamline production. Additionally, and when possible, design with modularity in mind for easy assembly, disassembly, and repair.

Materials and product scalability

Once you’ve designed your part, it’s time to think about materials. Here are a few things to consider when choosing a material for a scalable product.

-

Manufacturability. Be sure your material is compatible with the manufacturing process you want to use. For injection molding, thermoplastics like ABS or polycarbonate are preferable, because of their melt flow properties and ability to efficiently fill complex molds. For CNC machining, hard materials are not as suitable as those that are ductile. For FDM, SLS, and MJF additive manufacturing, we prefer thermoplastic polymers, whereas, for SLA additive manufacturing, it is common to use thermoset polymers (resin).

-

Availability and lead times. Materials that are readily available and have short lead times will help ensure consistency for large-scale production. For example, metals like aluminum or steel are widely available and have established supply chains – and thus are often used to manufacture scalable products.

-

Cost-efficiency. Like your product’s design, balance is key – in this case between performance and cost. Engineering plastics such as nylon or polypropylene offer a good balance of performance and affordability.

-

Mechanical properties. Consider properties such as tensile strength, impact resistance, and stiffness – and whether your product needs them.

Post-processing and product scalability

Once your part has been manufactured, it may still need one or more post-processing techniques. Here, as in material selection and part design, you will need to think strategically.

-

Defining the purpose. The purpose of post-processing could be to have visually appealing parts or to enhance the surface strength or quality, such as corrosion resistance or wear resistance, etc. This means it is critical to determine this during the design phase, allowing you to define the active area of the part and select the right post-processing technique.

-

Environmental effect. Some post-processing techniques can be detrimental to the environment, which means it is better to avoid redundant processes. If the purpose of your product is clearly defined (as described above), you can potentially save a lot of time and energy during production.

-

Compatibility with automation. The post-processing techniques you use should be able to be easily automated. Certain surface finishes, such as polishing, have automation potential, but you should first consult with your manufacturing partner before making any hard decisions.

-

Material compatibility. Make sure your post-processing techniques are compatible with your chosen materials. For example, thermal treatments like annealing or stress relieving should be tailored to the material's properties to prevent distortion or material damage.

-

Complex design. Depending on your product’s geometry, post-processing might be required to remove support material. For example, when it comes to additive manufacturing, defining printing orientation correctly might help reduce post-processing time, thus decreasing production times.

-

Correct tolerances. Some post-processing techniques, such as type III anodizing, require high-thickness coatings. This means you should always consider and plan for your product’s tolerances.

Start a production project

Find out more about our complete order management for producing end-use parts. We offer a huge range of quality documentation and have manufacturing partners in our network with various industry certifications.

Frequently asked questions

Why is scalability important?

Scalability allows you to meet growing demand, maintain competitiveness, and efficiently adapt to changing market conditions.

How does scalability affect production costs?

Scalability often leads to lower production costs per unit, as economies of scale are achieved with increased production volumes.

Can scalability impact product quality?

If not properly managed, scalability can negatively potentially impact product quality due to increased production volumes or changes in manufacturing processes.