Design for injection molding

Injection molding is repeatable, reliable and highly efficient. It's often the best manufacturing solution for creating hundreds and thousands of parts, and the go-to for mass production. Learning how to optimize designs for injection molding will help you reduce costs, manufacture parts faster and ensure better consistency across production runs.

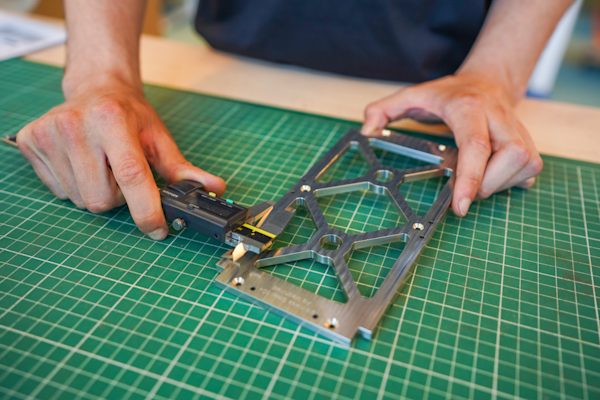

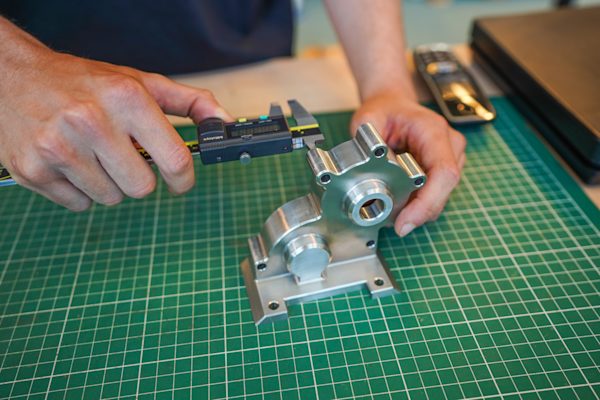

What is GD&T? How to reduce manufacturing errors and improve quality

What is Geometric Dimensioning and Tolerancing (GD&T) and how is it used? This article explores the basics of how and when to use GD&T to get the best results out of custom part manufacturing.

How to avoid common defects in injection molding

What are the most common defects in the injection molding process and how do you avoid them? This article provides six essential design tips for avoid production defects while reducing the cost and lead time of your molded parts.

What’s the best SPI surface finish for your injection molded part?

What SPI surface finishes does Protolabs Network have for injection molding custom parts? Check out the standard SPI mold finishes we offer and our material recommendations to get the most out of injection molding.

What is design for manufacturability (DFM)?

Design for manufacturing (DFM) means taking a design-first approach to manufacturing. In this article, we look at the overall DFM process, the necessary steps for a successful outcome, examples of DFM done right and how to get the most out of your own processes.

How do you design parts for injection molding?

How do you optimize part design for injection molding? This complete guide to designing for injection molding provides basic and advanced design tips, including guidelines for creating snap-fits, living hinges and undercuts, and accounting for optimial surface finishes.

What materials have the best repeatability?

Seeking consistency and predictability in your parts? Check out our guide on repeatability, which highlights the materials that will perform the same way time and time again.

Guide to designing for product scalability

How can you create a part or product that’s ready to move from prototype to production? Check out our article, which offers tips and tricks for designing with scalability in mind.

When to use 3D printing vs when to use injection molding

Learn what to consider when making a choice between 3D printing and injection molding, the benefits of each manufacturing method, and more.

How do you design undercuts for injection molding?

Want to learn how to design undercuts that don’t cause damage to your parts? Check out our article, which offers tips and tricks for DFM with undercuts, examples of when you might need them, and more.

Undercuts in injection-molded parts present a host of challenges to designers and manufacturers. In this article, we’ll take a look at the definition of undercuts, their purpose, applications, and tips for designing parts with them.