The Knowledge Base

Learn to design better parts for 3D printing, CNC machining, injection molding and sheet metal fabrication. Compare materials and post-processing methods. Keep leveling up your digital manufacturing expertise.

Learn how to manufacture better parts

Industry and lifecycle

How to manufacture parts for different industries and product lifecycle stages.

Read more3D printing

How do 3D printers turn digital models into physical parts?

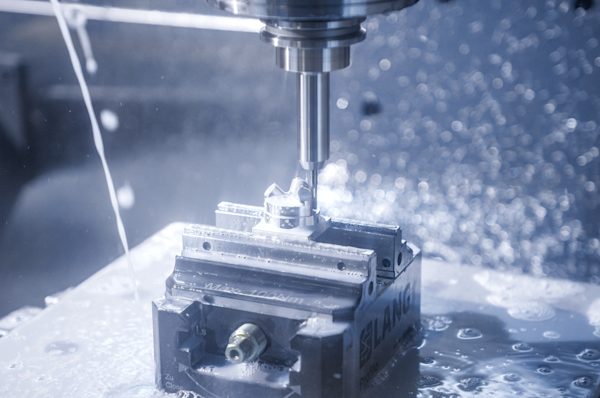

Read moreCNC machining

How do CNC machines make complex, precise parts?

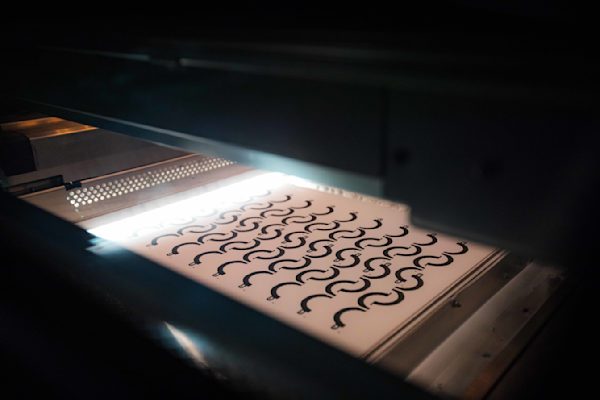

Read moreInjection molding

How does injection molding produce tons of parts efficiently?

Read moreDesign for 3D printing

How do you design parts for 3D print manufacturing?

Read moreDesign for CNC machining

How do you design parts for better CNC precision?

Read moreDesign for injection molding

How do you design parts for manufacturing at scale?

Read moreMaterials for manufacturing

What are custom parts made of?

Read morePost-processes & finishes

Understanding materials for manufacturing and how to get the most out of the last step of the manufacturing process?

Read moreStandards & technical data

What are the technical standards for digital manufacturing? Bookmark these rules and resources.

Read moreWhat engineers are reading now

Your complete, practical resource for everything digital manufacturing

Digital manufacturing is a complex topic. There’s always more to learn, especially as designers and engineers develop astounding new technologies and manufacturing processes evolve (and automate). The more you know about manufacturing technologies like 3D printing, CNC machining, injection molding and sheet metal fabrication, the better equipped you are to design products that can be manufactured easily and at the price point that works for you.

For nearly a decade, Protolabs Network has worked to produce comprehensive resources to help you develop revolutionary products. These include The 3D Printing Handbook, our complete guides on every Protolabs Network technology and the Knowledge Base, a growing collection of articles for new and seasoned engineers. The Knowledge Base is a tool for learning about manufacturing technologies, how to design for every process, key standards and best practices and a lot more.

The manufacturing knowledge in this resource will help you develop products faster and more cost-efficiently, advising on custom part sourcing for any stage of the innovation process. Whether you’re creating an initial prototype, sourcing parts for a more functional prototype, looking to scale toward full production or making parts to bring an older product back to life, the Knowledge Base is here to guide you.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quote