Whether you’re creating a prototype, a single part, or a high-volume production run, you’ll need a deep understanding of the manufacturing method you are using. Typically – and especially if you are creating plastic parts – this method will be either 3D printing or injection molding.

In this article, we’ll explore each method’s benefits, focusing on factors such as production volume, budget constraints, design complexity, material selection, surface finish needs, turnaround time, and tolerances.

What is 3D printing?

3D printing, a type of additive manufacturing, is a method in which parts are created layer by layer in a 3D printer. Parts are typically created with plastic or metal (this process is known as Direct Metal Laser Sintering), and are based on digital models. It is extensively used in the engineering industry, especially for prototypes.

What is injection molding?

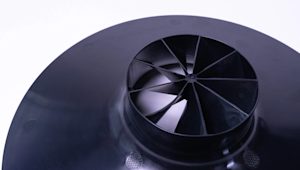

In injection molding, polymer granules are melted and injected under pressure into a mold. When the material cools and solidifies, it takes the shape of the mold. This results in identical parts with good tolerances. Injection molding is one of the most widely used manufacturing methods. Almost every plastic part around you was manufactured using injection molding.

How to choose between 3D printing and injection molding

When making a decision between 3D printing and injection molding, you’ll need to consider several basic factors about your project or the parts you intend to create. Let’s take a look at them – and at the questions you should ask yourself or your team regarding them – so we can be sure you’ll have all the information you need to make the best choice.

-

Production volume. How many parts do you need or intend to create? Will production volumes remain relatively consistent, or could there be fluctuations in demand?

-

Budget. What is the budget for your project or production run? Is the initial investment or per-unit cost more important?

-

Design complexity. How complex is the geometry of the part you intend to create? Does it contain or need undercuts, overhangs, or intricate features?

-

Material selection. Does your part require certain properties, such as strength? Do you need a wide range of materials to choose from?

-

Surface finish. Does your part need a certain surface finish or appearance, such as texture or smoothness? Will it need post-processing, such as vapor smoothing?

-

Turnaround time. How quickly do you need your parts? Will you need to create prototypes?

-

Part tolerances. How precise and/or tight do your parts’ tolerances need to be? Is there room for variation?

-

Physical and mechanical properties. What forces or environments will your parts be subjected to? Will they be under high pressure? Exposed to chemicals or high temperatures?

-

Functionality. Does your part need to be waterproof? Is weight a factor? How critical is ease of maintenance?

Once you have answers to the above questions, you’ll have a clearer idea of which technology to choose. You can use the below sections to get an idea of what manufacturing method – 3D printing or injection molding – will be best suited to your project.

When should you use 3D printing?

If your project aligns with one or more of the following criteria, you might want to consider 3D printing.

-

Prototyping and rapid iteration. 3D printing is typically a faster overall process than injection molding, as it does not require you to first create a mold or other tooling. This makes it a great choice if you’ll need to rapidly prototype and iterate on your part’s design.

-

Low to moderate production volumes. Because of its fast turnaround time, 3D printing lends itself well to – and is cost-effective for – small batch runs of parts.

-

Low setup costs. Because you don’t have to factor in mold creation, 3D printing often has a lower initial cost than injection molding. Read more about the costs of 3D printing.

-

Complex geometries. 3D printing parts can feature complex, intricate geometries without incurring a great deal of additional cost.

-

Material versatility. You’ll have more choice of materials with 3D printing. Additionally, you can create parts that consist of multiple materials. Find out more in our article on 3D printing for industrial purposes.

-

Time sensitivity. If you need a small quantity of parts in a short amount of time, 3D printing may be your best option.

When should you use injection molding?

If your project aligns with one or more of the following criteria, injection molding may be the best option.

-

Mass production. Injection molding is highly efficient for large-scale or mass production due to its faster cycle times. However, you’ll also need to factor the time it takes to create a mold. This means per-unit costs may be lower than 3D printing, but setup costs could be higher. Find out about the most common applications.

-

Part consistency. Parts created with injection molding are highly repeatable and exhibit very consistent quality. If your parts have tight tolerances, injection molding may be the best choice.

-

Parts with simple designs. Injection molding is suitable for simpler designs at higher volumes.

-

Strong parts. Injection molded parts are usually stronger than 3D printed parts, because they consist of one solid part, compared to the multiple layers of 3D printed parts.

-

Low per-unit costs. While injection molding may have higher initial setup costs, it is much more cost-effective for large production runs with a lower per-unit cost than 3D printing. Read about the costs of injection molding.

-

Smooth surfaces. 3D printed parts are created layer by layer. This means layer lines are usually visible on finished parts, and would require post-processing to achieve a smooth surface. Injection molding, however, results in smooth surfaces without post-processing.

At a glance – 3D printing or injection molding?

In a hurry? Let’s take a 30-second look at when you should choose 3D printing or injection molding.

In general, 3D printing is best suited for:

-

Low production volumes

-

Prototypes

-

Complex or intricate designs

-

Parts that consist of multiple materials

-

Fast turnaround times

-

Low initial setup costs

In general, injection molding is best suited for:

-

High-volume production

-

Consistent, repeatable parts

-

Simple designs

-

Single-material parts with high strength

-

Parts with smooth surfaces

-

Low per-unit costs

Start your next project

To create a part with 3D printing, upload a CAD file to receive an instant free quote and comprehensive DFM analysis. For injection molding, receive a detailed quote from our experts.

For more assistance with choosing the right production method for your project, refer to our articles on injection molding, 3D printing, and 3D printing for industrial purposes.

Frequently asked questions

Is 3D printing or injection molding faster?

3D printing is faster for prototyping, but injection molding is faster for large-scale production.

Can injection molding produce complex designs?

Yes, but they may result in incur higher tooling costs.

Is 3D printing or injection molding cheaper?

Injection molding involves higher initial tooling costs, but per-unit costs are lower large production runs.

Can 3D printing achieve the same surface finish as injection molding?

You can achieve smooth surfaces on 3D printed parts, but you may need to add a post-process to them to do so.

Which method is more flexible for design changes?

3D printing is more flexible for design changes as it doesn't involve the use of molds. This makes iterations faster and easier.